RSCI Sprag Type One Way Clutch Bearing

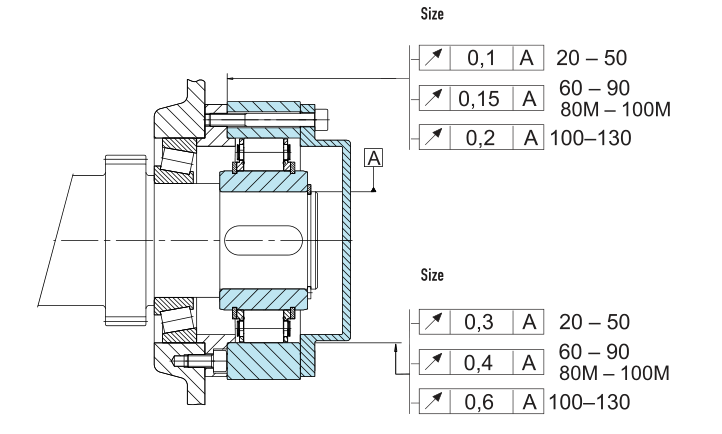

Type RSCI is a centrifugal lift off freewheel one way clutch with the inner race rotating. Only the inner race is designed for freewheeling. It is a non self- supported type.

Bearings must be provided to ensure concentricity of the inner and outer races support axial and radial loads, as shown overleaf.

Concentricity and runout limits must be observed. The RSCI type accepts all types of lubricant currently used in power transmission equipment. It is possible to mount these freewheels directly in gear-boxes without separate lubrication. An oil mist is generally sufficient. Grease lubrication may be acceptable if the unit works mostly in overrunning condition, as on E-motors.

When used as a backstop, it must be checked that the overrunning speed will not go below the minimum speed given in the characteristics table.

|

Size |

Torque |

Speeds |

NO. |

|

Weight

|

|||||||||||||||||

|

|

||||||||||||||||||||||

|

dH7 |

TKN1) |

nmax2) |

nimin3) |

nimax4) |

D5) |

D1h6 |

D2H7 |

D3 |

D4 |

z |

L |

I |

I1 |

I4 |

f×45° |

dmin |

m |

tmin |

||||

|

[mm] |

[Nm] |

[min-1] |

[min-1] |

min-1 |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

[kg] |

|||||

|

180 |

31500 |

115 |

285 |

1300 |

412 |

240 |

310 |

360 |

M20 |

12 |

90 |

80 |

53 |

5 |

3.5 |

280 |

18.6 |

3 |

59 |

|||

|

180M |

50000 |

90 |

220 |

1300 |

422 |

240 |

310 |

370 |

M20 |

18 |

120 |

120 |

83 |

0 |

4 |

280 |

18.5 |

2 |

92 |

|||

|

180II |

63000 |

115 |

285 |

1300 |

412 |

240 |

310 |

360 |

M20 |

24 |

160 |

160 |

118 |

0 |

3.5 |

280 |

21 |

3 |

116 |

|||

|

180II-M |

100000 |

90 |

220 |

1300 |

425 |

240 |

310 |

370 |

M24 |

24 |

240 |

240 |

176 |

0 |

4 |

280 |

32 |

3 |

190 |

|||

|

220 |

42500 |

110 |

265 |

1100 |

470 |

290 |

360 |

410 |

M20 |

16 |

105 |

80 |

60 |

12.5 |

4 |

330 |

19.5 |

3 |

90 |

|||

|

220M |

68000 |

85 |

205 |

1100 |

480 |

290 |

360 |

410 |

M24 |

16 |

120 |

120 |

83 |

0 |

4 |

330 |

18.5 |

2 |

109 |

|||

|

220II |

85000 |

110 |

265 |

1100 |

480 |

290 |

360 |

430 |

M24 |

18 |

160 |

160 |

130 |

0 |

4 |

330 |

15 |

3 |

159 |

|||

|

220II-M |

136000 |

85 |

205 |

1100 |

490 |

290 |

360 |

425 |

M30 |

20 |

240 |

240 |

176 |

0 |

4 |

330 |

32 |

2 |

249 |

|||

|

240 |

52000 |

105 |

250 |

1100 |

500 |

320 |

390 |

440 |

M20 |

16 |

105 |

90 |

60 |

7.5 |

4 |

360 |

15 |

2 |

95 |

|||

|

240M |

83000 |

80 |

195 |

1100 |

520 |

320 |

390 |

440 |

M24 |

16 |

120 |

120 |

83 |

0 |

4 |

360 |

18.5 |

2 |

137 |

|||

|

240II |

104000 |

105 |

250 |

1100 |

520 |

320 |

390 |

440 |

M24 |

24 |

180 |

180 |

132 |

0 |

4 |

360 |

24 |

2 |

191 |

|||

|

240II-M |

166000 |

80 |

195 |

1100 |

530 |

320 |

390 |

455 |

M30 |

24 |

240 |

240 |

181 |

0 |

4 |

360 |

32 |

2 |

250 |

|||

|

260 |

65000 |

100 |

240 |

1000 |

550 |

360 |

430 |

500 |

M24 |

16 |

105 |

105 |

60 |

0 |

4 |

400 |

22.5 |

2 |

130 |

|||

|

260M |

100000 |

75 |

185 |

1000 |

580 |

360 |

430 |

500 |

M24 |

24 |

125 |

125 |

83 |

0 |

4 |

400 |

21 |

2 |

183 |

|||

|

260II |

130000 |

100 |

240 |

1000 |

580 |

360 |

430 |

500 |

M24 |

24 |

210 |

210 |

132 |

0 |

4 |

400 |

39 |

2 |

262 |

|||

|

260II-M |

200000 |

75 |

185 |

1000 |

580 |

360 |

430 |

500 |

M30 |

24 |

250 |

250 |

176 |

0 |

4 |

400 |

37 |

2 |

369 |

|||

|

300 |

78000 |

90 |

225 |

1000 |

630 |

410 |

480 |

560 |

M24 |

24 |

105 |

105 |

60 |

0 |

4 |

460 |

22.5 |

3 |

174 |

|||

|

300M |

125000 |

70 |

175 |

1000 |

630 |

410 |

480 |

560 |

M24 |

24 |

125 |

125 |

83 |

0 |

4 |

460 |

21 |

3 |

210 |

|||

|

300II |

156000 |

90 |

225 |

1000 |

630 |

410 |

480 |

560 |

M24 |

24 |

210 |

210 |

134 |

0 |

4 |

460 |

38 |

3 |

351 |

|||

|

300II-M |

250000 |

70 |

175 |

1000 |

630 |

410 |

480 |

560 |

M30 |

24 |

250 |

250 |

182.6 |

0 |

4 |

460 |

33.7 |

3 |

457 |

|||

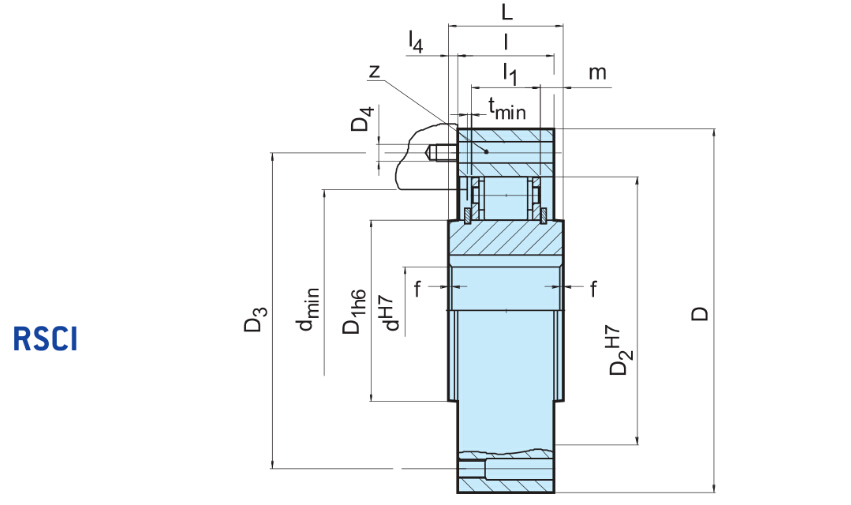

Mounting example: