PEEK/PI high temperature resistant PTFE/PVDF corrosion resistant POM/PA ultra-precision plastic bearings

Description

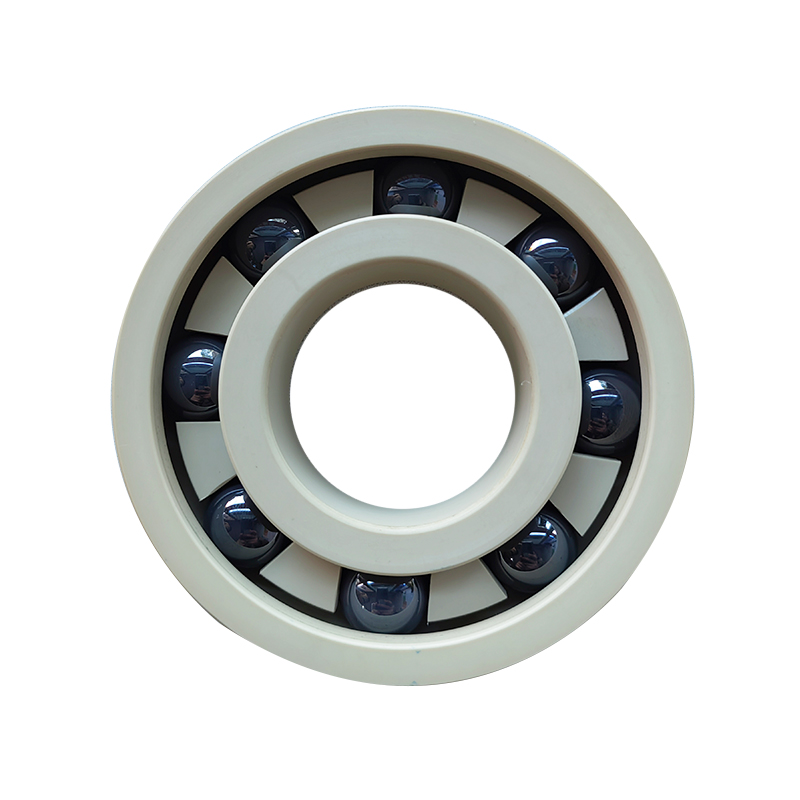

PEEK/PI plastic bearings (high temperature resistant plastic bearings)

As emerging engineering plastic materials, PEEK and PI have been proven to have the best mechanical strength, dimensional stability and high temperature resistance among all known engineering plastics. Among them, PEEK's long-term

use temperature reaches 260C, and PI's long-term use temperature is as high as 300C. It has excellent corrosion resistance and can still operate freely in medium-strength acid and alkali corrosive environments. Therefore, it is

generally used to make bearings that need to operate precisely in relatively harsh environments. Its disadvantage is that the material itself is relatively expensive, so the cost of use is relatively high. High, generally the inner

and outer ring materials are PEEK or PI, the cage materials are PTFE, PEEK or P1, and the balls are generally ZrO2 or Si3N4 ceramic balls.

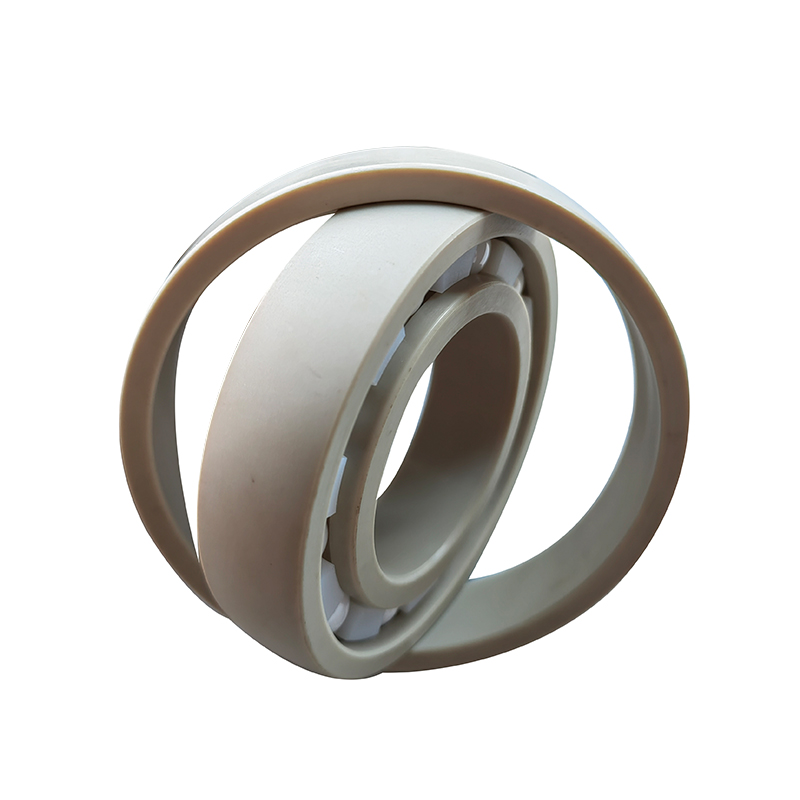

PTFE/PVDF plastic bearings (corrosion-resistant plastic bearings)

As the most typical varieties of fluoroplastics, PTFE and PVDF have the best corrosion resistance. PTFE has the best corrosion resistance among all known engineering plastics and can be used in all concentrated acid and alkali situations,

including HF and fuming sulfuric acid and nitric acid (more than 98%), etc., and have good high temperature performance. PTFE is proven to be able to be used at high temperatures of 180C. PVDF can also be used at 150C, but the PTFE material

has extremely low mechanical strength and poor dimensional stability. Temperature deformation is large, and PVDF has better overall performance in comparison. Generally, PTFE or PVDF is used as the material of the inner and outer rings,

PTFE or PVDF as the cage material, and the balls are generally glass balls or ceramic balls.

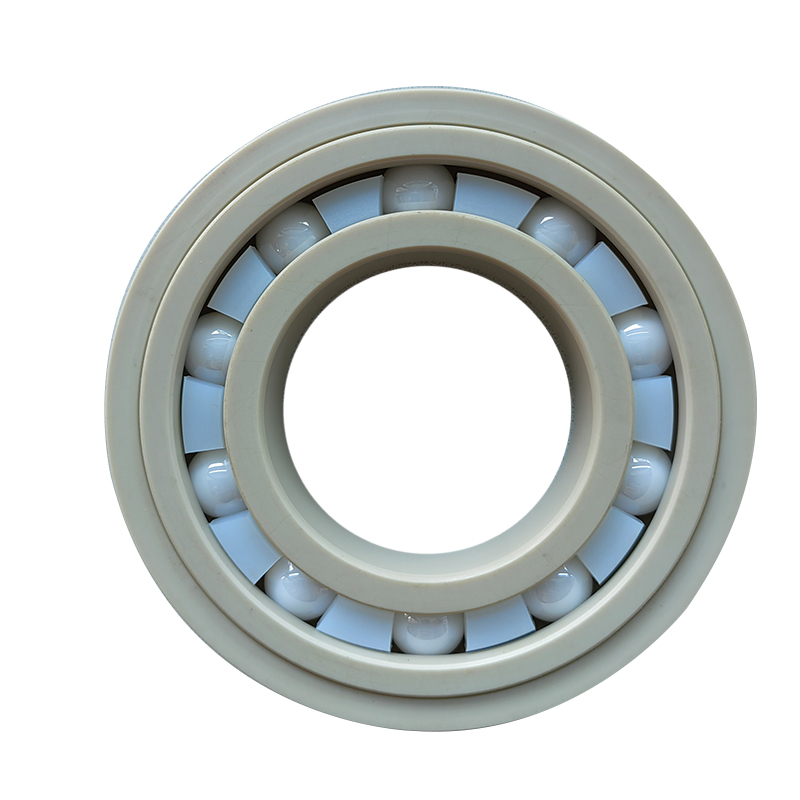

POM/PA plastic bearings (precision plastic bearings)

Generally, the inner and outer balls are made of POM or PA, and the cage is made of glass fiber reinforced nylon 66 (GRPA66-25). The balls are glass balls, stainless steel balls or ceramic balls. This kind of bearing performs well

in alkaline environments but is not suitable for acidic corrosion. environment.