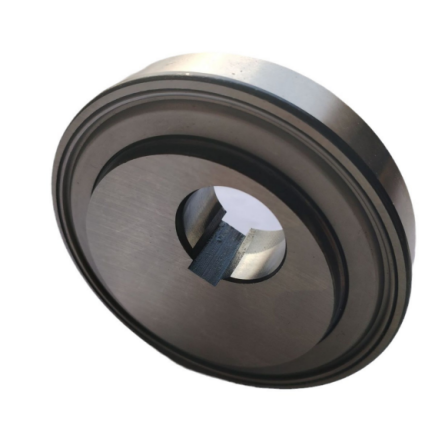

maintenance free 88102 eccentric bearing for agriculture machinery

Eccentric bearings have become a popular choice in various industries due to their unique advantages. One of the most significant benefits of these bearings is that they are maintenance-free. Once installed, eccentric bearings require no additional maintenance to function at their optimum level. This is because of their self-lubricating design, which eliminates the need for regular lubrication and reduces overall maintenance costs and effort required.

Unlike conventional bearings that need frequent lubrication to ensure smooth operation, eccentric bearings have an innovative design that incorporates self-lubricating properties. This means that the bearing is equipped with lubrication channels and reservoirs, allowing it to distribute oil or grease internally. As a result, the bearing can continuously lubricate itself during operation, ensuring smooth movement and preventing friction and wear.

The maintenance-free nature of eccentric bearings offers several advantages. Firstly, it reduces the overall cost of maintenance for industries and businesses. Traditional bearings often require regular lubrication, which adds to the ongoing maintenance cost. However, with eccentric bearings, this cost is significantly reduced as there is no need for constant lubrication. This can result in substantial cost savings over time, making eccentric bearings a cost-effective solution.

Secondly, the maintenance-free nature of eccentric bearings eliminates the need for regular inspection and lubrication, saving time and effort. Industries that rely on bearings for their operations can benefit greatly from this feature. With less time spent on maintenance tasks, businesses can focus on more critical aspects of their operations, improving productivity and efficiency.

Furthermore, eccentric bearings also support small batch customization, ensuring that each customer's specific needs are met. This level of customization allows for optimal performance and efficiency, as the bearings can be tailored to meet specific requirements. Whether it is for heavy-duty applications or specialized machinery, eccentric bearings can be customized to provide the best results.

In conclusion, the maintenance-free nature of eccentric bearings offers significant advantages for various industries. Not only do they eliminate the need for regular lubrication, reducing maintenance costs, and effort, but they also support customization, ensuring optimal performance for individual requirements. With these benefits, eccentric bearings have become a preferred choice for many industries seeking reliable and efficient bearing solutions.

1.Made of bearing steel, it has large bearing capacity, reduces cracks and extends service life.

2.Ingenious production process, corrosion resistance, quality guaranteed

3.Smooth surface, fine workmanship and texture

88102 Bearings are critical components used in machinery. These bearings play a vital role in ensuring smooth and efficient operation of machinery during the harvesting process.

|

Packaging & Delivery: |

|

|

Packaging Details |

Standard exporting packing or according to the customer's requirements |

|

Package Type: |

A. Plastic tubes Pack + Carton + Wooden Pallet |

|

|

B. Roll Pack + Carton + Wooden Pallet |

|

|

C. Individual Box +Plastic bag+ Carton + Wooden Palle |