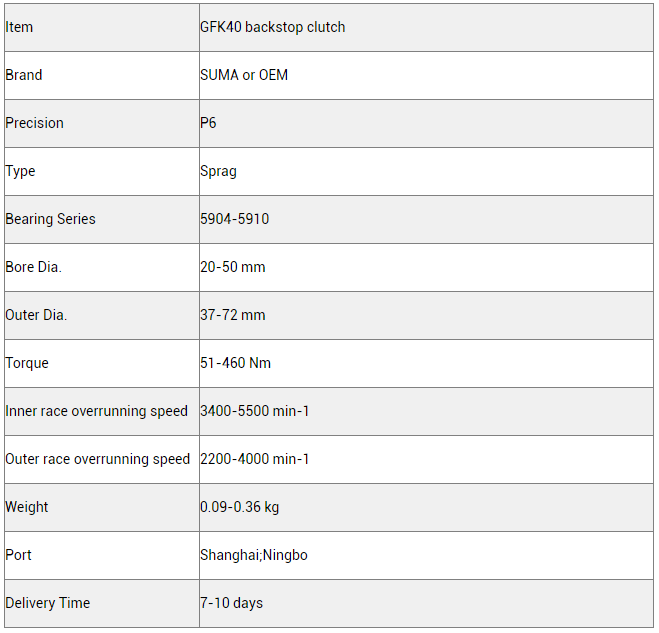

FGK GFK 35 40 45 High Speed Sprag Oneway Backstop Clutch Bearing

Production Introduction

Ball Bearing Is A Kind Of Rolling Bearing. The Ball Is Installed Between The Inner Steel Ring And The Outer Steel Ring And Can Bear Large Load. Also Called Ball Bearing.

Ball Bearing Is Mainly Composed Of Four Basic Elements: Ball, Inner Ring, Outer Ring And Retainer, Also Known As Cage Or Retainer.

The Purpose Of A Ball Bearing Is To Determine The Relative Position Of Two Parts (Usually A Shaft And A Housing) And To Ensure Their Free Rotation, While Transferring The Load Between Them. At High Rotational Speeds (Eg In Gyro Ball Bearings) This Use Can Be Extended To Include Free Rotation With Little Wear In The Bearing. To Achieve This State, The Two Parts Of The Bearing Are Separated By An Adherent Fluid Film Called An Elastohydrodynamic Lubricating Film.

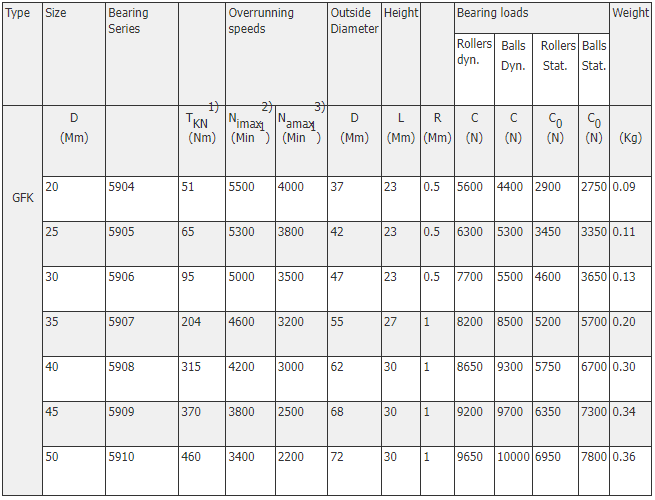

Type GFK Is A Sprag Type Freewheel Integrated Into A 59.Series Ball Bearing. This Design Provides High Torque Capacity For Minimal Outside Diameter. It Is A Bearing Supported Type, Delivered Grease Lubricated. Oil Bath Lubrication Is Also Possible. Whatever The Lubrication Type, Seals Should Be Provided, As Illustrated On The Next Page. Torque Transmission Must Be Ensured By A Press Fit Assembly Into A Rigid Outer Housing With R6 Tolerance, And Onto A Shaft With P5 Tolerance. Initial Radial Clearance Has Been Provided To Take Into Account This Heavy Press Fit. Operating Temperature Range: -20°C To +100°C. Peaks Up To +120°C Are Acceptable For Short Periods. Please Contact Us For Higher Temperatures.

Products Parameters