Sep . 28, 2025 06:55 Back to list

4-Hole UCFC 200 Series Bearing - Xingtai Botong|Heavy Load, Self-Aligning, Sealed Design

Introduction

The 4-Hole UCFC 200 Series Bearing is a specialized mechanical component designed to provide reliable performance in demanding industrial applications. This bearing combines the features of a pillow block bearing and a flange cartridge bearing into a single, integrated unit. Its robust design, self-aligning capabilities, and resistance to contaminants make it a preferred choice across various sectors, including automotive, agriculture, and construction. This article delves into the product's features, technical specifications, applications, and the background of its manufacturer, Xingtai Botong Machinery Technology Co., Ltd.

Product Overview

The UCFC 200 series bearing is a unitized pillow block flange cartridge bearing, designed to simplify installation and enhance durability. It integrates a spherical outer ring with a built-in flange, an inner ring with a cylindrical bore, and a set of balls held in place by a cage. The flange allows for secure mounting on machinery or structures, while the spherical outer ring ensures self-alignment, reducing wear and tear caused by misalignment.

The UCFC bearing is particularly suited for high-speed rotation and heavy-duty equipment due to its ability to distribute loads evenly across the balls and rings. This design minimizes the risk of failure under extreme conditions, making it ideal for applications where reliability is critical.

Key Features and Advantages

1. Heavy Load Capacity

The UCFC 200 series bearing is engineered to withstand heavy and shock loads. Its robust construction ensures that the load is evenly distributed, reducing stress on individual components. This feature is particularly beneficial in applications involving heavy machinery, such as construction equipment and agricultural tools.

2. Self-Aligning Capability

The spherical outer ring allows for slight misalignment between the shaft and housing, compensating for deviations that may occur during operation. This self-aligning feature reduces friction, minimizes wear, and extends the bearing's lifespan, ultimately improving the efficiency of the machinery it powers.

3. Sealed Design

The UCFC bearing is sealed on both sides, providing a protective barrier against contaminants such as dust, dirt, and moisture. This sealing mechanism ensures consistent performance even in harsh environments, making it suitable for outdoor and industrial applications.

4. Versatile Applications

Due to its durability and adaptability, the UCFC 200 series bearing is widely used in the automotive industry for engine components, in agriculture for machinery like tractors and harvesters, and in construction for equipment such as cranes and excavators. Its versatility is a key factor in its popularity across multiple sectors.

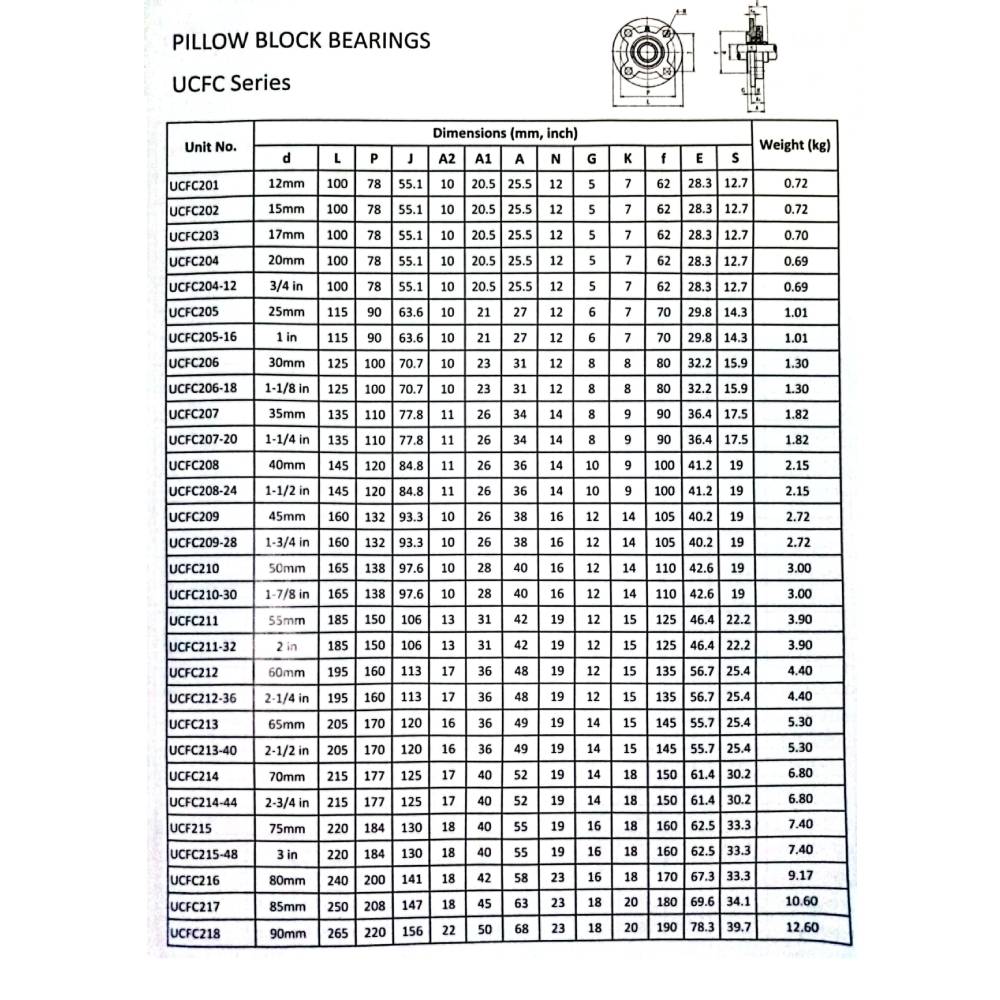

Technical Specifications

The UCFC 200 series bearing is available in various sizes and configurations to meet specific application requirements. Below is a detailed specification table outlining the product's key parameters:

| Parameter | Details |

|---|---|

| Outer Ring Type | Spherical with Flange |

| Inner Ring Bore | Cylindrical |

| Ball Configuration | Caged Balls |

| Load Capacity | Heavy and Shock Loads |

| Sealing | Double-Sided Sealed |

| Mounting | Flange Bolted to Housing |

| Material | High-Strength Steel |

Applications in Industry

The UCFC 200 series bearing is a critical component in various industrial applications. Here are some of the key areas where it is utilized:

1. Automotive Industry

In automotive engines, the UCFC bearing supports high-speed rotation and absorbs shock loads, ensuring smooth operation. Its sealed design protects against oil and debris, making it suitable for use in vehicle components such as alternators and water pumps.

2. Agricultural Machinery

Tractors, harvesters, and other agricultural equipment rely on the UCFC bearing for its durability and resistance to harsh environments. The self-aligning feature is particularly valuable in ensuring consistent performance under varying conditions.

3. Construction Equipment

Construction machinery like cranes, excavators, and bulldozers benefit from the UCFC bearing's ability to handle heavy loads and withstand extreme temperatures. Its flange mounting simplifies installation, reducing downtime during maintenance.

Company Background: Xingtai Botong Machinery Technology Co., Ltd

Xingtai Botong Machinery Technology Co., Ltd is a leading manufacturer and supplier of high-quality bearings, including the UCFC 200 series bearing. With a focus on innovation and precision, the company has established itself as a trusted name in the industry. Their commitment to quality is reflected in their rigorous testing processes and adherence to international standards.

As a spherical roller bearing material manufacturer, Xingtai Botong ensures that their products meet the highest performance criteria. They also serve as a spherical roller bearing material exporter, supplying bearings to clients worldwide. Their extensive product range and customer-centric approach have earned them a reputation for reliability and excellence.

Packaging and Delivery

Xingtai Botong offers flexible packaging options to ensure the safe transportation of their UCFC 200 series bearings. The standard packaging includes:

- A. Plastic Tubes Pack + Carton + Wooden Pallet

- B. Roll Pack + Carton + Wooden Pallet

- C. Individual Box + Plastic Bag + Carton + Wooden Pallet

Custom packaging solutions are also available upon request, allowing clients to choose the option that best suits their needs. The company ensures that all bearings are securely packed to prevent damage during transit.

Conclusion

The 4-Hole UCFC 200 Series Bearing is a versatile and durable solution for a wide range of industrial applications. Its unique design, combined with the expertise of Xingtai Botong Machinery Technology Co., Ltd, ensures that it meets the demands of even the most challenging environments. Whether in automotive, agriculture, or construction, this bearing delivers reliable performance and long-term value.

References

NIST (National Institute of Standards and Technology) plays a critical role in advancing technology through precise measurements and standards. Their work in material testing and engineering standards ensures the reliability of components like the UCFC 200 series bearing. For more information, visit the NIST website.

Latest news

-

Custom 6007 Ball Bearing – Tailored Solutions for Industrial Reliability

NewsNov.24,2025

-

Custom Small Spherical Bearings - Precision Solutions for Global Industries | BTZ Bearing

NewsNov.23,2025

-

Custom Silicon Nitride Balls - Durable, Lightweight Ceramic Precision Components

NewsNov.22,2025

-

Custom Spherical Bearing Replacement | Tailored Solutions for Industry Uptime

NewsNov.22,2025

-

Custom Silicon Nitride Ceramic Bearings: Durable & Efficient Solutions for Advanced Industries

NewsNov.20,2025

-

Custom AG Bearings - Enhance Agricultural Equipment Performance and Durability

NewsNov.19,2025