Oct . 01, 2025 03:25 Back to list

4-Hole UCFC 200 Series Bearing - Xingtai Botong Machinery Technology Co., Ltd.

The 4-Hole UCFC 200 Series Bearing with Flanged Cartridge Units is a critical component in industrial machinery, offering robust performance and versatility. Designed for heavy-duty applications, this bearing combines the advantages of a pillow block and flange cartridge into a single unit. Manufactured by Xingtai Botong Machinery Technology Co., Ltd., the UCFC 200 series is engineered to meet the demands of diverse industries, including automotive, agriculture, and construction. This article explores its features, technical specifications, application scenarios, and the company’s commitment to quality.

Product Overview

The UCFC 200 series bearing is a unitized pillow block flange cartridge bearing, integrating a spherical outer ring with a built-in flange, an inner ring with a cylindrical bore, and a set of balls held by a cage. This design allows for seamless installation and removal, making it ideal for applications requiring frequent maintenance. The flange provides a stable mounting surface, ensuring secure attachment to machinery or structures. The UCFC 200 series is available in multiple configurations, catering to specific load and alignment requirements.

Key Features and Advantages

Heavy Load Capacity

The UCFC 200 series is designed to withstand heavy loads and shock loads, distributing stress evenly across the balls, inner ring, and outer ring. This ensures longevity and reduces the risk of mechanical failure. Its robust construction makes it suitable for high-speed rotation and demanding environments.

Self-Aligning Capability

The spherical outer ring allows for self-aligning properties, compensating for minor misalignments between the shaft and housing. This feature minimizes friction and wear, extending the bearing’s lifespan and improving machine efficiency. Xingtai Botong Machinery emphasizes this advantage in their product design, ensuring optimal performance even in challenging conditions.

Contamination Protection

Sealed on both sides, the UCFC 200 series prevents contamination from dust, dirt, and moisture. This sealing mechanism maintains the bearing’s performance in harsh environments, making it a reliable choice for outdoor and industrial applications.

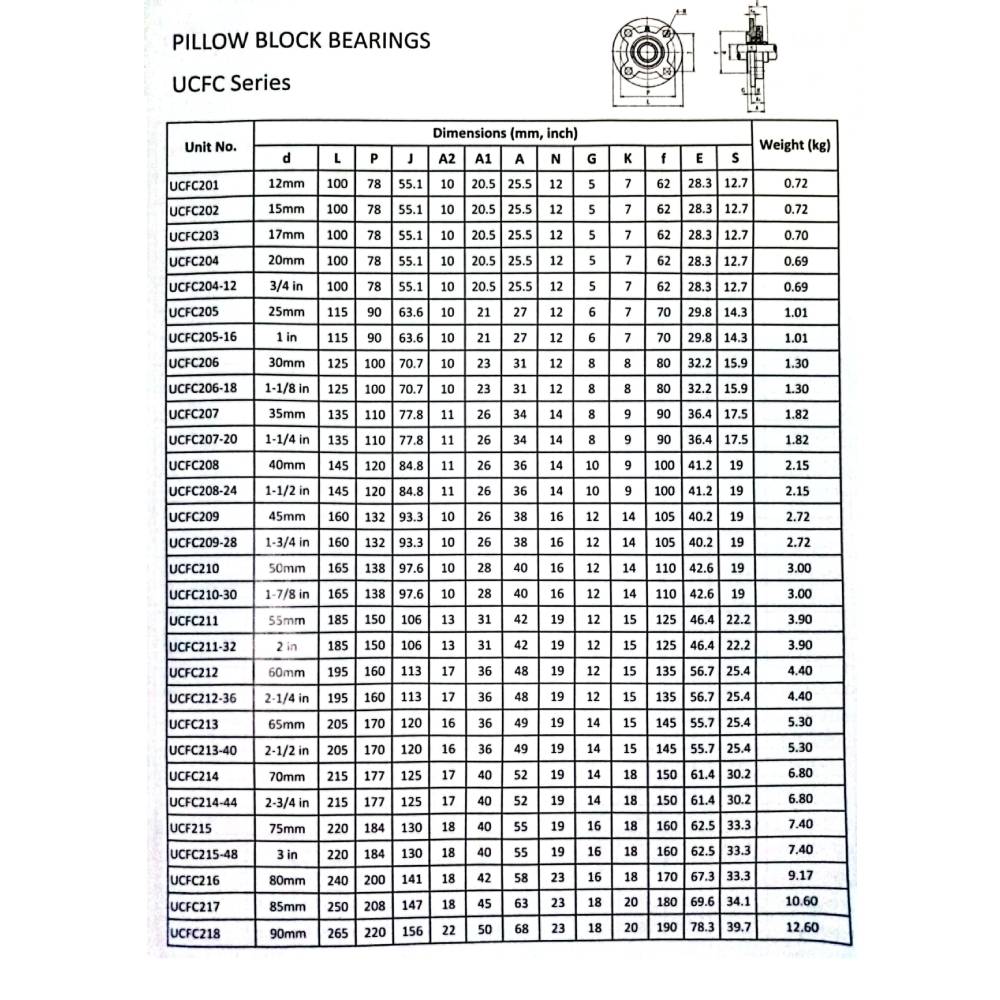

Technical Specifications

| Product Name | 4-Hole UCFC 200 Series Bearing |

|---|---|

| Series | UCFC 200 |

| Bearing Type | Spherical Roller Bearing |

| Load Capacity | High-Load Capacity (Refer to manufacturer specifications) |

| Sealing | Double-Sided Sealed |

| Alignment | Self-Aligning |

| Material | High-Carbon Steel with Heat Treatment |

Application Scenarios

The UCFC 200 series is widely used in the following industries:

- Automotive: Ideal for engine components, transmission systems, and suspension units.

- Agriculture: Suitable for tractors, harvesters, and irrigation equipment.

- Construction: Used in excavators, bulldozers, and conveyor systems.

- Manufacturing: Essential for machinery requiring high load-bearing and self-aligning capabilities.

Company Background

Xingtai Botong Machinery Technology Co., Ltd. is a leading manufacturer and exporter of bearings, specializing in spherical roller bearing material suppliers and exporters. Based in Xingtai, China, the company has built a reputation for innovation, quality control, and customer-centric solutions. With a dedicated R&D team, Xingtai Botong ensures its products meet international standards, including those referenced by NIST (National Institute of Standards and Technology).

Packaging and Delivery

The UCFC 200 series is packaged in multiple configurations to suit customer needs:

- Package Type A: Plastic tubes + Carton + Wooden Pallet

- Package Type B: Roll Pack + Carton + Wooden Pallet

- Package Type C: Individual Box + Plastic Bag + Carton + Wooden Pallet

Why Choose the UCFC 200 Series?

The UCFC 200 series stands out due to its combination of durability, versatility, and ease of maintenance. Its self-aligning design reduces downtime, while the double-sided sealing ensures reliability in harsh environments. For businesses seeking a spherical roller bearing material manufacturer, Xingtai Botong offers a trusted solution with competitive pricing and global delivery.

Conclusion

The 4-Hole UCFC 200 Series Bearing with Flanged Cartridge Units is a testament to engineering excellence, combining strength, adaptability, and precision. Whether for automotive, agricultural, or construction applications, this bearing delivers consistent performance. Xingtai Botong Machinery Technology Co., Ltd. continues to lead in the spherical roller bearing material exporter market, ensuring customers receive high-quality products that meet global standards.

References

NIST (National Institute of Standards and Technology) provides guidelines for mechanical components, including bearings. While specific NIST standards for the UCFC 200 series were not found, general industry benchmarks for load capacity, material durability, and sealing mechanisms are referenced in this article. For further details, visit https://www.nist.gov.

Latest news

-

Custom 6007 Ball Bearing – Tailored Solutions for Industrial Reliability

NewsNov.24,2025

-

Custom Small Spherical Bearings - Precision Solutions for Global Industries | BTZ Bearing

NewsNov.23,2025

-

Custom Silicon Nitride Balls - Durable, Lightweight Ceramic Precision Components

NewsNov.22,2025

-

Custom Spherical Bearing Replacement | Tailored Solutions for Industry Uptime

NewsNov.22,2025

-

Custom Silicon Nitride Ceramic Bearings: Durable & Efficient Solutions for Advanced Industries

NewsNov.20,2025

-

Custom AG Bearings - Enhance Agricultural Equipment Performance and Durability

NewsNov.19,2025