Feb . 22, 2024 09:57 Back to list

Ceramic Bearings: Overview of Features and Advantages

Table of content

1.Structure and Function of Ceramic Bearings

2.Ceramic bearings have widespread applications in various industries

An Overview

Ceramic bearings are a special type of bearing where both the rolling elements and inner/outer rings are made of ceramic materials. While traditional bearings typically use metal or alloy materials, ceramic bearings leverage the properties and advantages of ceramics. Ceramic bearings capitalize on the characteristics of ceramic materials, offering benefits such as high wear resistance, corrosion resistance, and high-temperature resistance.

25MM UCFL305-16 Flange Unit Medium Duty BearingT

1.Structure and Function of Ceramic Bearings

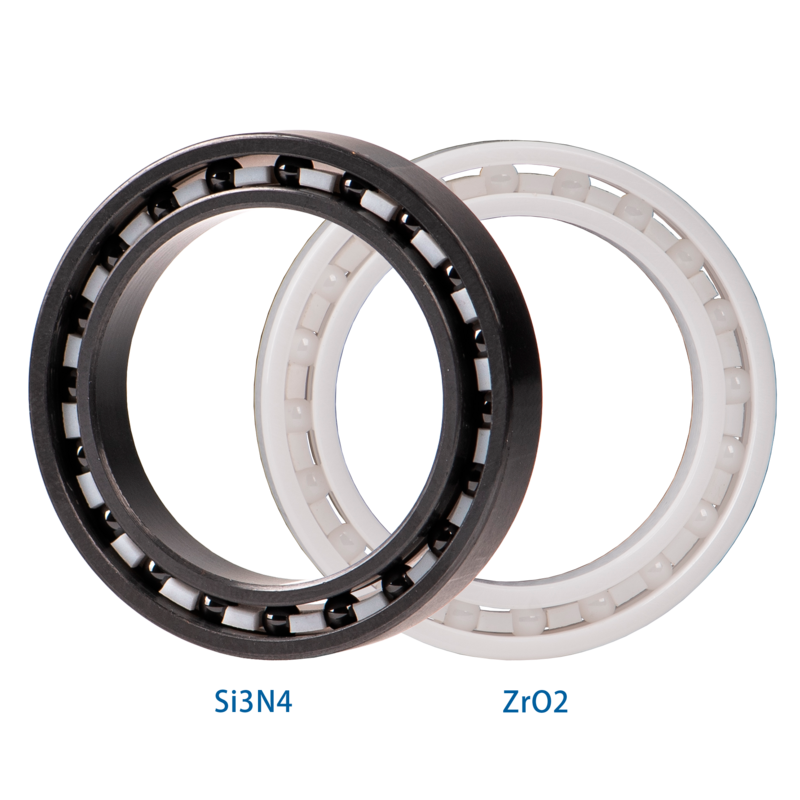

There are two main types of ceramic materials used in bearings:

zirconia ceramics (ZrO2) and silicon nitride ceramics (Si3N4). Both of these materials have excellent characteristics, allowing ceramic bearings to perform exceptionally well in specific applications.

Ceramic bearings have the following advantages:

- Firstly, ceramic bearings have superior wear resistance. Ceramic materials have high hardness and low friction coefficient, enabling ceramic bearings to withstand greater loads in high-speed and high-temperature environments while reducing wear and heat generation. This wear resistance makes ceramic bearings highly suitable for applications that require high speeds, high temperatures, and long service life.

- Secondly, ceramic bearings have excellent corrosion resistance. Ceramic materials exhibit excellent chemical stability, allowing them to operate for extended periods in harsh environments without being affected by corrosion. This makes ceramic bearings suitable for applications involving corrosive media or high humidity, such as in the chemical and marine industries.

- Additionally, ceramic bearings have lower thermal expansion coefficients and higher rigidity, which helps reduce deformation and vibration during operation, thereby improving the precision and stability of the bearings.

![]() Further Reading: Ceramic Bearing Specifications: Overview of Materials and Characteristics

Further Reading: Ceramic Bearing Specifications: Overview of Materials and Characteristics

In summary, ceramic bearings are a special type of bearing made of ceramic materials, offering superior wear resistance, corrosion resistance, and high-temperature performance. They provide excellent performance in applications requiring high speeds, high temperatures, and resistance to corrosion. However, their selection and application should be based on specific circumstances and considerations.

2.Ceramic bearings have widespread applications in various industries

Here are the common industrial uses of ceramic bearings:

High-speed machinery

Ceramic bearings are frequently used in high-speed machinery equipment such as high-speed power tools, turbo machinery, and wind turbines due to their excellent wear resistance and high-speed capabilities.

Corrosive environments

Ceramic bearings possess exceptional corrosion resistance, making them widely used in corrosive environments found in industries such as chemical manufacturing, marine engineering, and oil extraction.

High-temperature environments

Ceramic bearings can maintain excellent performance in high-temperature environments, making them extensively utilized in high-temperature industrial sectors such as steel smelting, glass production, and high-temperature furnaces.

HIGH TEMPERATURE BEARINGS

Medical equipment

Due to their excellent biocompatibility and low friction properties, ceramic bearings are widely employed in medical devices such as artificial joints, dental equipment, and medical imaging devices.

BEARINGS FOR MEDICAL INDUSTRY

Semiconductor manufacturing

Ceramic bearings find application in high-vacuum and high-temperature environments in the semiconductor manufacturing process. They are used to support and operate equipment, ensuring process stability and precision.

Aerospace

Ceramic bearings are extensively used in the aerospace industry due to their lightweight, high-temperature performance, and wear resistance. They are applied in aircraft turbine engines, aviation powerplants, and rocket engines.

It is important to note that the requirements and application environments differ in each industry. Therefore, when selecting and applying ceramic bearings, it is crucial to evaluate and choose based on specific application requirements to ensure proper operation and long lifespan of the bearings.

Latest news

-

25x52x44.4mm UEL205 Bearing with Eccentric Sleeve

NewsAug.19,2025

-

High Quality 6319 2RS Deep Groove Ball Bearing 95x200x45

NewsAug.18,2025

-

UCT205-15 Take Up Housing Pillow Block Bearing | Reliable

NewsAug.17,2025

-

CKZ-A Sprag Type Freewheels One Way Clutch - High Performance & Reliable

NewsAug.16,2025

-

ASNU 12-35 NFS TFS Roller Freewheel One Way Clutch Bearings

NewsAug.15,2025

-

Durable AK208 Pillow Block Housing | Reliable Bearing Support

NewsAug.14,2025