Apr . 29, 2024 10:32 Back to list

What do you know about Spherical Roller Bearings?

Despite what their name may imply, spherical roller bearings are not truly spherical in shape. The rolling elements of spherical roller bearings are mainly cylindrical in shape, but have a profile that makes them appear like cylinders that have been slightly over inflated. As with every other kind of bearing, the purpose of these bearings is to reduce friction between moving parts, but their design is meant to permit greater angular misalignment than other cylindrical bearings.

W208PPB6 Agriculture DISC Harrow Bearing

Spherical roller bearings typically consist of an inner ring with two raceways inclined at an angle to the bearing axis, an outer ring with a common spherical raceway, spherical rollers, cages and in certain designs also internal guide rings or center rings. The design of these bearings means that they are naturally self-aligning and can handle very heavy radial and axial loads at moderate speeds. The internal design of these bearings is not standardized by ISO, so it varies between different manufacturers and different series.

Spherical roller bearings can be found in a variety of applications including gear boxes, wind turbines and pumps. They are most commonly made from chrome steel with cages made from brass, machined steel, sheet steel or polyamide.

Latest news

-

Spherical Bearing Installation

NewsJun.11,2025

-

Sphere Bearing Applications About Key Uses

NewsJun.11,2025

-

Long-Lasting Bearing Options

NewsJun.11,2025

-

Deep Groove Ball Bearing Basics

NewsJun.11,2025

-

Comprehensive Guide to Zirconia Bearing Testing

NewsJun.11,2025

-

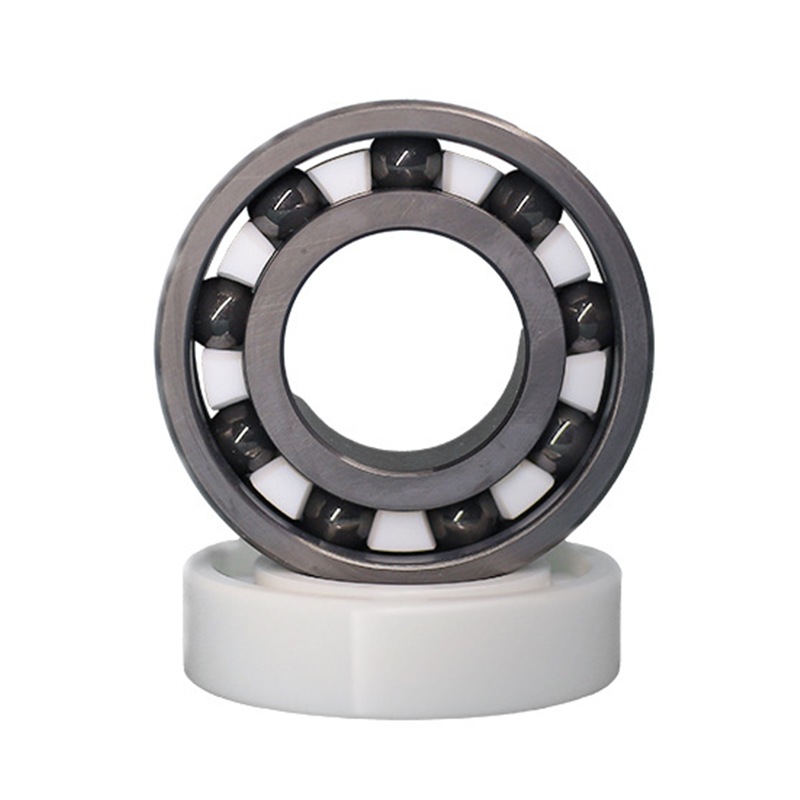

Ceramic Bearing Selection Guide

NewsJun.11,2025