Apr . 29, 2024 10:36 Back to list

Understanding Tapered vs. Spherical Roller Bearings

Choosing the right bearing can feel like navigating a labyrinth of acronyms and technical jargon. But fear not gearheads! Today, we’re taking the mystery out of two powerhouse players in the bearing world: Tapered Roller Bearing vs. Spherical Roller Bearing. Get ready to dive into the deep end of load capacities, misalignment tolerance, and the nitty-gritty of how these champions of rotation keep the industrial world humming

Whether you’re a seasoned engineer navigating complex machinery or a curious tinkerer building your dream workshop cart, understanding the nuances of Tapered Roller Bearing vs. Spherical Roller Bearings and finding the best bearings and bushes suppliers will empower you to make informed decisions and keep your projects spinning smoothly. So, buckle up, grab your grease rag, and let’s delve into the thrilling world of bearing mechanics!

What is Tapered Roller Bearings?

Tapered roller bearings embody a specialized design featuring tapered rollers positioned amidst inner and outer ring raceways. These rollers are engineered with inner and outer ring raceways and rollers that converge at a singular point along the bearing axis, creating conical apices. These bearings utilize trapezoidal tapered rollers guided by a substantial rib on the inner ring.

Benefits of Tappered Roller Bearings

- High Load-Carrying Capacity: Noteworthy for their capacity to support substantial loads owing to a larger contact area facilitated by their tapered design.

- Precision and Operational Accuracy: Famed for precision, ideal for applications demanding meticulous control over bearing movements and loads.

- Handling Axial and Radial Loads: Versatile in managing both axial (thrust) and radial loads, a unique trait derived from their design.

Common Applications of Tapered Bearings

Automotive Industry

- Car Wheel Bearings: Both tapered and spherical roller bearings are used, with tapered bearings preferred for their ability to handle combined radial and axial loads in high-speed applications. For independent suspension systems, spherical roller bearings can provide better misalignment tolerance.

- Drivetrain Components: Tapered roller bearings are often found in transmissions, differentials, and propeller shafts due to their high load capacity and ability to handle both radial and axial forces.

-

W208PPB6 Agriculture DISC Harrow Bearing

- Steering Systems: Spherical roller bearings can be found in steering linkages and columns due to their ability to accommodate misalignment from road imperfections and maneuvering.

Heavy Machinery

- Construction Equipment: Tapered roller bearings are crucial in excavators, loaders, and bulldozers for their exceptional load capacity and resistance to shock loads. Spherical roller bearings can be found in applications with high misalignment, like bucket linkages and slewing rings.

- Mining Equipment: Both bearings are used in crushers, mills, and conveyors due to their durability and ability to handle harsh environments and heavy loads. Tapered bearings handle combined loads, while spherical bearings accommodate misalignment in rotating components.

Agricultural Equipment

- Tractors and Combine Harvesters: Tapered roller bearings are used in axles, gearboxes, and PTO shafts due to their high load capacity and resistance to dust and dirt. Spherical roller bearings can be found in steering systems and implement linkages for their misalignment tolerance.

- Tillage Equipment: Both bearings are used in plows, cultivators, and planters due to their ability to handle heavy loads and resist wear and tear in demanding soil conditions.

Latest news

-

Spherical Bearings Enabling Bionic Joint Over-Rotation

NewsAug.22,2025

-

Stainless Steel Sphericals: Botong's Harsh-Environment Heroes

NewsAug.22,2025

-

Spherical Roller Thrust Bearings For Space Elevator Anchors

NewsAug.22,2025

-

Axial Spherical Roller Bearing: Xingtai's Motion Architects

NewsAug.22,2025

-

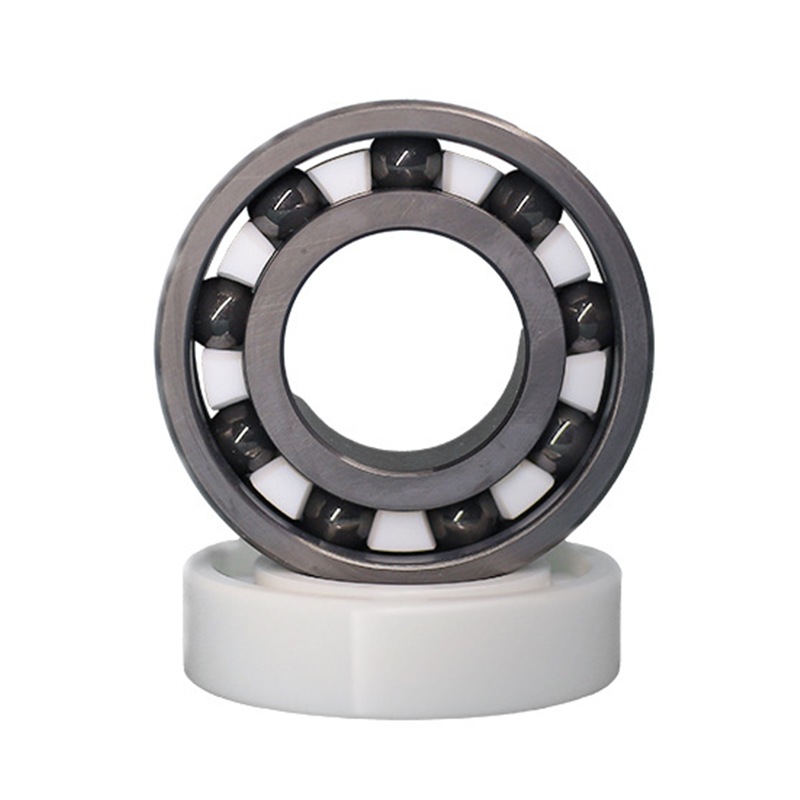

Ceramic Coated Bearings For Fusion Reactor Plasma Whirlpools

NewsAug.22,2025

-

Botong's Zirconia Bearing: Defying Metal Limits

NewsAug.22,2025