May . 27, 2024 11:56 Back to list

Are ceramic bearings worth it?

Why do riders choose ceramic bearings for mountain bikes?

Bearings live a challenging component life in any off-road bike, especially if you are riding in the UK, or notoriously muddy regions of Europe or North America.

Suppose you are a committed all-weather rider, invested in severe weather gear, allowing you to ride all year. In that case, your mountain or gravel bike’s wheel hub and bottom bracket bearings will be exposed to a lot of potential mud contact and moisture ingress. Even the slightest trace of dirt or grime inside a bearing assembly starts becoming a grinding agent – ruining the perfectly spherical shape of your bearings and shortening their lifecycle.

Grime as a grinding agent is one issue, but moisture ingress is the other, triggering rust with traditional steel bearings. Ceramic bearings don’t corrode and rust, as steel bearings do when moisture seeps into your bottom bracket, hubs or headset. For mountain bikers seeking true ‘fit-and-forget’ components that contain bearings, the appeal of ceramic’s corrosion resistance is obvious.

Ceramic bearings spin better

The theoretical long-term maintenance benefits of ceramic bearings are appealing but for many riders, ceramic bearing upgrades to their bottom bracket, hubs or drivetrain pulleys are performance-related.

Ceramic bearings are nearly a third harder than steel. That means greater force can be applied during manufacturing, creating a more perfectly spherical shape with smaller tolerances. Because ceramic bearings are much harder than steel and more perfectly round, there’s a lower probability of misalignment and friction losses over time.

But does a tiny reduction in friction matter when you pedal a mountain bike across uneven and textured terrain, where smooth cadence and power transfer aren’t possible, as it would be on a track bike, riding at a velodrome?

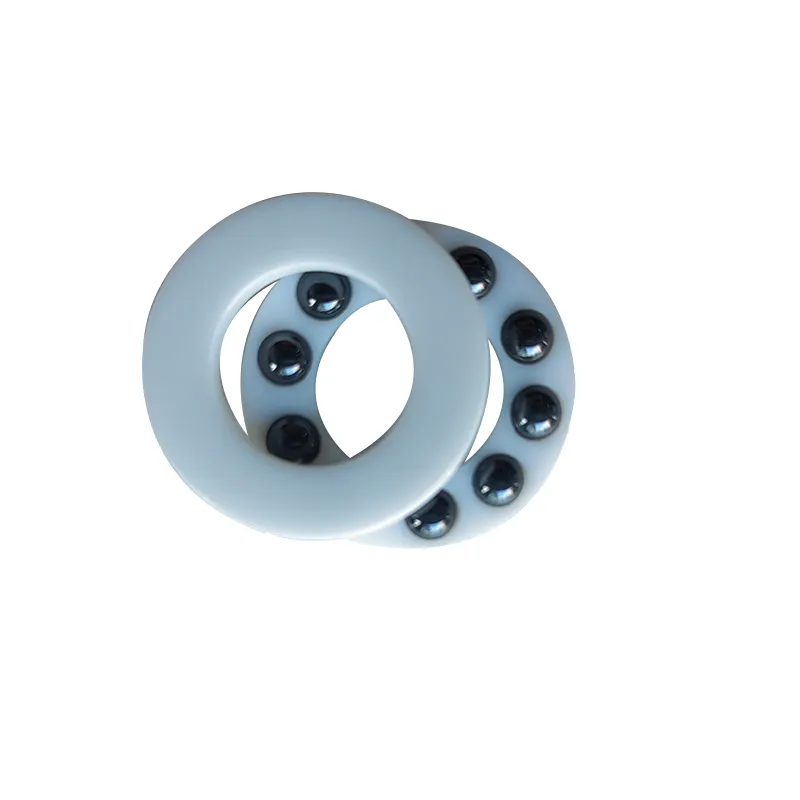

Ceramic Ball Bearings

The rotational speed counterargument

As with all deeply technical features in off-road cycling, like aero or carbon strength, there’s a lot of laboratory and test data supporting specifics of the ceramic bearing efficiency argument. In isolation, ceramic bearings do spin with less friction than steel – the difference is undeniable. But whether it makes an actual difference at mountain biking speeds, is debatable.

Ceramic bearing upgrades are very expensive. Although they can save a few watts, in theory, most mountain bikers will never spin the cranks with enough revolutions per minute to benefit from the friction reduction. It would help if you spun dizzyingly high revolutions to benefit from ceramic bearings and their lower coefficient of friction, but rider biomechanics are too mild.

A real-world example is comparing how ceramic bearings are used for industrial applications, where the friction reduction benefits are unlocked by machinery spinning at 20 000rpm. That’s a lot more than a 300rpm climbing cadence that riders might spin, when grinding along in 12th gear, on a 52t cassette.

For time trial road riders, the tiny friction reduction benefits that accumulate and compound on a slick TT bike built with ceramic hubs, bottom bracket, and drivetrain pulley wheels might make a tiny difference. But you’ll never notice the difference when grinding a mountain bike up that rocky Highlands climb.

The truth is that mountain bike cranks will never spin near the required cadence, to warrant a performance differential between ceramic and steel bearings for the argument of relatable riding efficiency. If they’re not going to save you that many watts during a mountain bike ride, why would you invest in ceramic bearings for your off-road bike?

Latest news

-

Durable PLC 110-190 Spherical Roller Bearing for Mixer Reducer

NewsAug.26,2025

-

CSK-2RS Sprag Clutch One Way Bearing: Sealed, High Torque, Durable

NewsAug.25,2025

-

CKZ-D Series One Way Overrunning Clutch: Reliable Power Control

NewsAug.24,2025

-

203KRR3 Round Bore Series Bearings | Cylindrical Outer Ring, Precision

NewsAug.23,2025

-

Top Spherical Roller Bearing Material Exporter - High Performance

NewsAug.22,2025

-

Durable UCFC202-09 Round Flange Housing 4-Bolt Ball Bearing

NewsAug.21,2025