May . 27, 2024 11:59 Back to list

Ceramic Bearings vs Steel Bearings: An Engineering Analysis

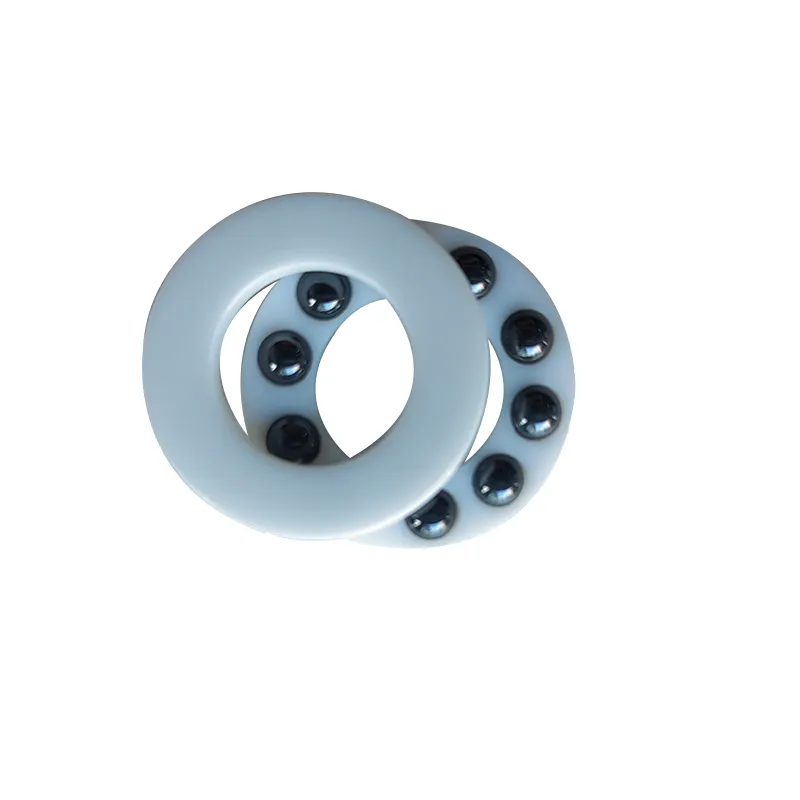

Internal Bearing construction – Ceramic bearings are not 100% ceramic

Ceramic bearings are in actual fact hybrid. They use ceramic balls and usually a steel inner and outer race. The ceramic balls are often silicon nitride or equivalent. Steel Bearings are commodity items that are composed of hardened steel balls and a steel inner and outer race. Geometrically, the contact points, inner and outer dimensions and thickness between steel and ceramic bearings is the same so they are interchangeable. The only real big noticeable difference between the two is the bearing clearance. On ceramic bearings, this is usually a C3 clearance whilst on steel it’s usually CN.

The bearing clearance is a measurement given to the small gap between the inner race, outer race and balls. It is required to prevent bearing seizure when it warms up and expands.

Another common difference in bearing construction is the cage type. The cage is required to keep the ball spacing even all of the way around the bearing. On steel bearings (usually by Japanese manufacturers NSK, NTN) the cage is a ribbon that is made from a piece of pressed metal and riveted between balls. This is a comparatively costly method of construction but improves friction characteristics at low speed and stiffness.

An alternative method of cage construction that has become popular is a composite or rubber cage. This cage snaps in and holds the ball spacing. Under high loads, the cage can often pop off or deforms and causes more friction. Almost all ceramic bearings use a composite or rubber cage.

External Bearing Construction – the Seals

Bearing seals come in 4 generic types. There are open bearings – these have no seals, metal shielded bearings – these have a metal strip over the bearing cage, non contact seal bearings and fully contacting sealed bearings.

In the bicycle industry, bearings generally have non contact or fully contacting seals. This is in light of the real risk of contamination from dirt and other ingress. In theory, non contacting seal will have the same friction level as a completely open unsealed bearing, in practice this is not quite the case because the seals generate a barrier for lubricant to ride up against and this is a frictional loss. Fully contacting seals touch both the inner and outer races to maintain the seal. This is definite frictional loss and they will always appear to be draggy when rotated in the hand. At operating speeds this loss from friction is still there but not so noticeable.

Basic bearing seal technology has not changed dramatically since the sixties and is largely governed by manufacturing costs rather than performance. Over time, the main improvements have come from sealing materials rather than geometrical differences.

Ceramic Ball Bearings

Bearing Production

Bearing production in volumes is an almost entirely automated process and was pioneered by the Japanese. The big four (SKF, NTN, NSK and FAG) produce thousands of bearings every second with little human intervention. The bearings are usually made on one site from raw material to boxed finished product. These bearings are almost always steel.

In contrast, the smaller ceramic suppliers (Enduro, Kogel, Ceramicspeed) have much more human intervention and often complete assembly of bearings by hand. The smaller companies do not have the ability to carry out the entire manufacturing process on site and typically subcontract the manufacturer of one or more parts of the bearing to a third party and then complete the final assembly in house.

Some suppliers of ceramic bearings buy in a generic hybrid assembly and laser etch their own brand name onto the side of the bearing. These bearings are purchased at very low sums ($5/£5/€5) from the far east and then sold on for 10 or even 20 times the price to consumers in the US and Europe. It’s easy to spot these manufacturers as they are usually sold by one supplier only and lack technical data.

There are three states. The first is out of the box. The second is the removal of grease and replacement with oil. The third is removal of grease, replacement of oil and removal of seals.

In out of the box configuration, the Enduro bearing has fractionally lower power loss. Once the grease has been removed, the power loss of both bearings is equal. After the seals have been removed, the NTN bearing has comfortably lower friction. This correlates well with the data provided by NTN, NSK, SKF and Schaeffler.

Bearing Friction vs Life

An often neglected part of tribology is how a bearing responds as it wears out. The graph below shows a comparison between two steel bearings (SKF and NTN) and a Ceramic bearing (Enduro). Initially the Enduro bearing has lower friction, at around 600km of use, the ceramic bearing has worn a track into the comparatively soft steel races and the bearing friction starts to increase dramatically. It is comfortably higher than steel bearings after a modest running in period. Hybrid ceramic bearings are the equivalent of trying to run a locomotive on an asphalt road – the hardness differential causes the road (raceway) to become damaged.

Total Power saving

The graph below shows how much power could be saved over 1000km between different bearing brands and their seal types. NTN, NSK and SKF dominate this chart and that is largely due to efficient seals and metal cages. The ceramic bearings which are coloured in red are not quite as efficient over a prolonged distance. If the evaluation window was extended to 10,000km, the ceramic bearings would perform much worse as a more significant track would have worn into the bearing races thereby increasing friction.

Latest news

-

Top Spherical Roller Bearing Material Exporter - High-Performance Alloys

NewsAug.27,2025

-

Durable PLC 110-190 Spherical Roller Bearing for Mixer Reducer

NewsAug.26,2025

-

CSK-2RS Sprag Clutch One Way Bearing: Sealed, High Torque, Durable

NewsAug.25,2025

-

CKZ-D Series One Way Overrunning Clutch: Reliable Power Control

NewsAug.24,2025

-

203KRR3 Round Bore Series Bearings | Cylindrical Outer Ring, Precision

NewsAug.23,2025

-

Top Spherical Roller Bearing Material Exporter - High Performance

NewsAug.22,2025