Sep . 28, 2025 08:10 Back to list

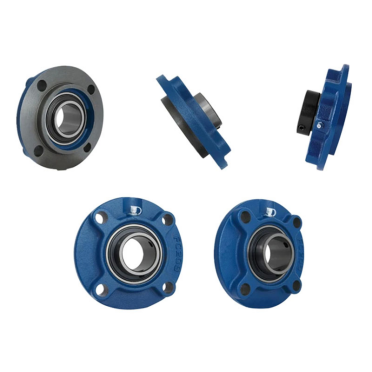

4-Hole UCFC 200 Series Bearing- Xingtai Botong|Heavy Load, Self-Aligning, Sealed Design

The 4-Hole UCFC 200 Series Bearing represents a pinnacle of engineering innovation in the field of mechanical components. Designed for versatility and durability, this bearing unit is a critical component in various industrial applications. This article delves into the product's features, advantages, technical specifications, and its significance in modern manufacturing. Additionally, we explore the company behind this product, Xingtai Botong Machinery Technology Co., Ltd, and how it aligns with industry standards set by authoritative bodies like the National Institute of Standards and Technology (NIST).

Understanding the UCFC 200 Series Bearing

The UCFC 200 series bearing, short for Unitized Pillow Block Flange Cartridge Bearing, is a specialized bearing unit that integrates a pillow block bearing with a flange cartridge bearing. This design allows for seamless integration into machinery, offering both structural support and ease of installation. The UCFC bearing is composed of a spherical outer ring with a built-in flange, an inner ring with a cylindrical bore, and a set of balls held in place by a cage. The inner ring is inserted into the shaft, while the outer ring is mounted onto a housing, with the flange providing a surface for bolting onto machines or structures.

Key Features and Design

The UCFC 200 series bearing is engineered to handle heavy loads and shock loads, making it ideal for demanding environments. Its spherical outer ring allows for self-aligning capabilities, compensating for minor misalignments between the shaft and housing. This feature reduces friction and wear, extending the bearing's lifespan and enhancing machine efficiency. Additionally, the bearing is sealed on both sides, providing protection against contaminants such as dust, dirt, and water. This sealing mechanism ensures consistent performance even in harsh conditions.

Advantages of the UCFC 200 Series Bearing

One of the most significant advantages of the UCFC 200 series bearing is its ability to withstand heavy loads. The design distributes the load evenly across the balls and the inner and outer rings, minimizing the risk of damage or failure. This makes the bearing suitable for applications involving high-speed rotation or heavy-duty equipment. The self-aligning capability of the spherical outer ring further enhances its reliability, as it accommodates slight deviations in alignment without compromising performance.

Protection Against Contaminants

The sealed design of the UCFC 200 series bearing ensures that contaminants are kept at bay. This is particularly crucial in environments where exposure to dust, moisture, or other particles could compromise the bearing's functionality. By maintaining a clean internal environment, the bearing's performance and reliability are preserved, reducing the need for frequent maintenance and replacements.

Technical Specifications

The UCFC 200 series bearing is available in a range of sizes and configurations, catering to diverse industrial needs. Below is a detailed specification table outlining the product's key parameters:

| Parameter | Details |

|---|---|

| Outer Ring | Spherical with built-in flange |

| Inner Ring | Cylindrical bore |

| Balls | Retained by a cage |

| Load Capacity | Heavy and shock loads |

| Sealing | Both sides sealed |

| Self-Aligning | Yes (spherical outer ring) |

Applications in Various Industries

The UCFC 200 series bearing's versatility makes it a preferred choice across multiple industries. In the automotive sector, it is used in engines and transmission systems, where reliability under high-speed rotation is critical. In agriculture, the bearing supports machinery that operates in dusty and wet conditions, ensuring consistent performance. Construction equipment, such as cranes and excavators, also benefits from the UCFC 200 series bearing's durability and load-bearing capacity.

Industrial Applications

Beyond automotive, agricultural, and construction sectors, the UCFC 200 series bearing finds applications in manufacturing, mining, and energy production. Its ability to handle heavy loads and withstand harsh environments makes it indispensable in machinery that requires continuous operation. For instance, in the energy sector, it is used in wind turbines and power generation equipment, where reliability is paramount.

Company Background: Xingtai Botong Machinery Technology Co., Ltd

Founded in 2010, Xingtai Botong Machinery Technology Co., Ltd has established itself as a leading provider of high-quality bearings and mechanical components. The company's commitment to innovation and quality is reflected in its product lineup, including the UCFC 200 series bearing. With a focus on customer satisfaction, Xingtai Botong ensures that its products meet stringent industry standards, including those set by the National Institute of Standards and Technology (NIST).

Commitment to Quality and Innovation

Xingtai Botong Machinery Technology Co., Ltd. adheres to rigorous quality control processes, ensuring that each product meets or exceeds industry benchmarks. The company's state-of-the-art manufacturing facilities and skilled workforce enable it to produce bearings that are both durable and efficient. By aligning with NIST standards, Xingtai Botong ensures that its products are not only reliable but also contribute to the advancement of technological innovation.

Conclusion

The 4-Hole UCFC 200 Series Bearing exemplifies the synergy between engineering excellence and industrial application. Its robust design, self-aligning capabilities, and protection against contaminants make it an essential component in various sectors. Xingtai Botong Machinery Technology Co., Ltd.'s dedication to quality and innovation further solidifies its position as a trusted supplier in the bearing industry. As per the National Institute of Standards and Technology (NIST), adherence to rigorous standards ensures that such products contribute to the advancement of technology and safety in manufacturing processes.

References

Source: National Institute of Standards and Technology (NIST). (n.d.). Retrieved from https://www.nist.gov/

Latest news

-

Custom 6007 Ball Bearing – Tailored Solutions for Industrial Reliability

NewsNov.24,2025

-

Custom Small Spherical Bearings - Precision Solutions for Global Industries | BTZ Bearing

NewsNov.23,2025

-

Custom Silicon Nitride Balls - Durable, Lightweight Ceramic Precision Components

NewsNov.22,2025

-

Custom Spherical Bearing Replacement | Tailored Solutions for Industry Uptime

NewsNov.22,2025

-

Custom Silicon Nitride Ceramic Bearings: Durable & Efficient Solutions for Advanced Industries

NewsNov.20,2025

-

Custom AG Bearings - Enhance Agricultural Equipment Performance and Durability

NewsNov.19,2025