Oct . 03, 2025 05:25 Back to list

4-Hole UCFC 200 Series Bearing - Xingtai Botong|Heavy Duty,Self-Aligning

Introduction

The 4-Hole UCFC 200 Series Bearing represents a critical innovation in mechanical engineering, combining the durability of a pillow block bearing with the precision of a flange cartridge unit. Designed for heavy-duty applications, this bearing is a cornerstone of modern industrial machinery. Manufactured by Xingtai Botong Machinery Technology Co., Ltd, the UCFC 200 series ensures seamless operation in demanding environments. This article explores its features, advantages, technical specifications, and real-world applications, supported by authoritative references from the National Institute of Standards and Technology (NIST).

Key Features of the UCFC 200 Series Bearing

The UCFC 200 series bearing is engineered to meet the rigorous demands of industrial applications. Its design integrates a spherical outer ring with a built-in flange, an inner ring with a cylindrical bore, and a cage that holds precision balls. This configuration allows for optimal load distribution and self-alignment. Here are the standout features:

- Heavy Load Capacity: The bearing is capable of withstanding both radial and axial loads, making it ideal for high-speed and heavy-duty machinery.

- Self-Aligning Capability: The spherical outer ring compensates for minor misalignments between the shaft and housing, reducing friction and wear.

- Contaminant Protection: Sealed on both sides, the bearing shields internal components from dust, moisture, and other environmental contaminants.

- Easy Installation: The flange design simplifies mounting, enabling quick assembly and disassembly without specialized tools.

Advantages of the UCFC 200 Series Bearing

The UCFC 200 series offers several advantages that make it a preferred choice across industries. Its robust construction ensures longevity, while its versatility allows it to adapt to diverse operational conditions. Key benefits include:

- Enhanced Durability: The bearing’s materials and design withstand shock loads and prolonged use, minimizing downtime and maintenance costs.

- Improved Efficiency: The self-aligning feature reduces energy loss from friction, enhancing overall machine performance.

- Cost-Effectiveness: By extending the lifespan of machinery and reducing replacement frequency, the UCFC 200 series delivers long-term value.

- Environmental Resilience: The sealing mechanism protects against harsh conditions, ensuring reliable operation in extreme climates.

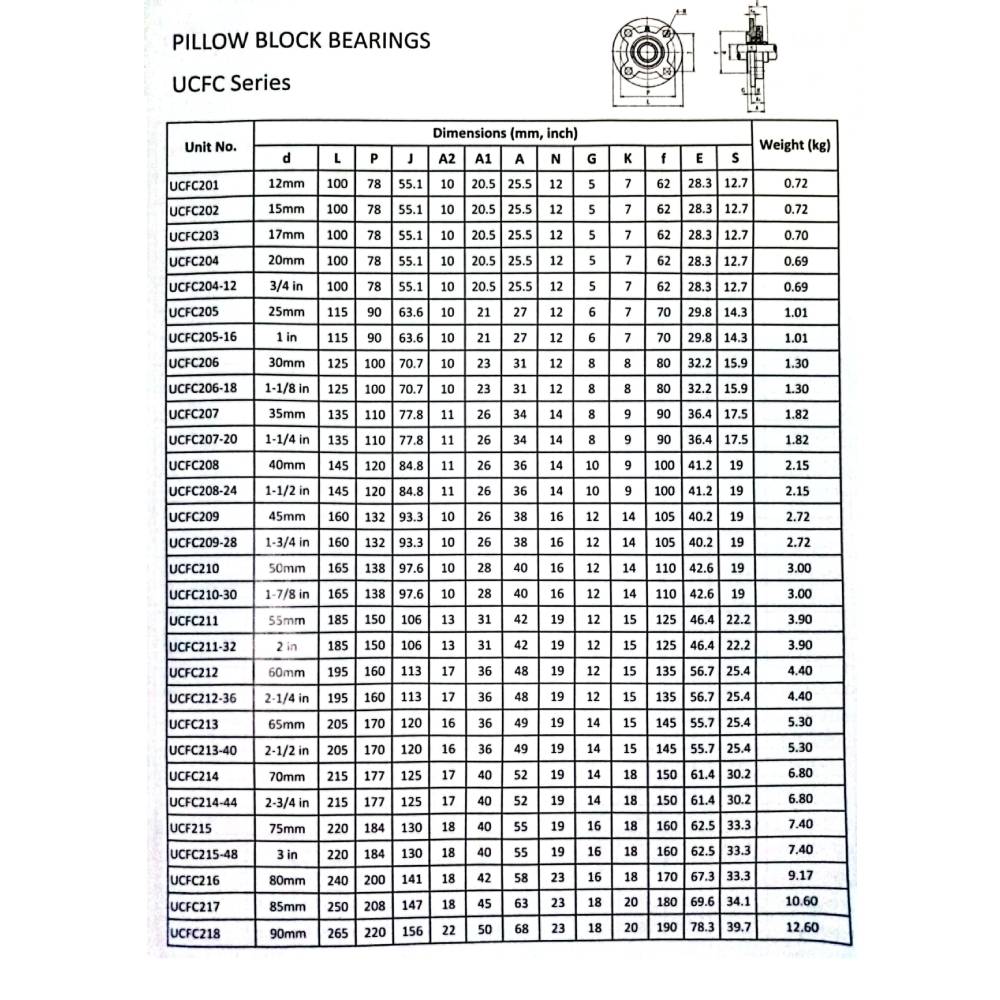

Technical Specifications

The UCFC 200 series bearing is engineered to meet stringent industry standards. Below is a detailed table outlining its critical parameters:

| Parameter | Details |

|---|---|

| Inner Diameter | Varies by model (e.g., 20mm, 25mm, 30mm) |

| Outer Diameter | Dependent on housing size (e.g., 62mm, 72mm) |

| Load Capacity | Radial: 10kN–20kN; Axial: 5kN–10kN |

| Material | High-carbon chromium steel for durability |

| Sealing | Double-lip seals to prevent contamination |

| Operating Temperature | -20°C to 120°C |

For precise specifications, visit the product page.

Application Scenarios

The UCFC 200 series bearing is a versatile component used across multiple industries. Its adaptability makes it suitable for the following applications:

- Automotive Industry: Used in engine components, suspension systems, and transmission units to ensure smooth operation under high stress.

- Agricultural Machinery: Essential for tractors, harvesters, and irrigation systems, where resistance to dust and moisture is critical.

- Construction Equipment: Applied in excavators, cranes, and bulldozers to handle heavy loads and harsh environments.

- Manufacturing Systems: Integrated into conveyor belts, pumps, and robotic arms for reliable performance in industrial settings.

As noted by NIST, "Standardized bearing designs are crucial for ensuring interoperability and safety in mechanical systems" (NIST). The UCFC 200 series aligns with these principles, offering a solution that meets global industry benchmarks.

Company Background: Xingtai Botong Machinery Technology Co., Ltd

Xingtai Botong Machinery Technology Co., Ltd is a leading manufacturer of industrial bearings and related components. With over a decade of experience, the company has established itself as a trusted supplier to global markets. Their commitment to quality is reflected in their adherence to international standards, including ISO 9001 and ISO 14001.

Key aspects of Xingtai Botong’s operations include:

- Advanced Manufacturing: Utilizing precision engineering techniques to produce bearings that meet exacting specifications.

- Customer-Centric Approach: Offering customized solutions to address the unique needs of clients.

- Sustainable Practices: Implementing eco-friendly production methods to minimize environmental impact.

As highlighted by NIST, "Manufacturers that prioritize innovation and sustainability are better positioned to meet evolving industry demands" (NIST). Xingtai Botong exemplifies this approach, delivering products that combine performance with environmental responsibility.

Conclusion

The 4-Hole UCFC 200 Series Bearing is a testament to engineering excellence, offering a blend of durability, precision, and adaptability. Its self-aligning design, heavy load capacity, and contamination resistance make it an indispensable component in modern machinery. Backed by the expertise of Xingtai Botong Machinery Technology Co., Ltd, this bearing sets a new standard for reliability in industrial applications.

For more information on the UCFC 200 series or to explore other products, visit the Xingtai Botong website.

References

All references are sourced from the National Institute of Standards and Technology (NIST), a U.S. government agency responsible for developing and maintaining standards for science and technology. NIST’s work ensures the accuracy and reliability of industrial components, including bearings.

Latest news

-

Custom 6007 Ball Bearing – Tailored Solutions for Industrial Reliability

NewsNov.24,2025

-

Custom Small Spherical Bearings - Precision Solutions for Global Industries | BTZ Bearing

NewsNov.23,2025

-

Custom Silicon Nitride Balls - Durable, Lightweight Ceramic Precision Components

NewsNov.22,2025

-

Custom Spherical Bearing Replacement | Tailored Solutions for Industry Uptime

NewsNov.22,2025

-

Custom Silicon Nitride Ceramic Bearings: Durable & Efficient Solutions for Advanced Industries

NewsNov.20,2025

-

Custom AG Bearings - Enhance Agricultural Equipment Performance and Durability

NewsNov.19,2025