Oct . 06, 2025 01:30 Back to list

4-Hole UCFC 200 Bearing-Durable, Self-Aligning, Heavy-Duty | Xingtai Botong

The 4-Hole UCFC 200 Series Bearing with Flange Cartridge Units is a specialized mechanical component designed to enhance performance in demanding industrial environments. Combining the functionalities of a pillow block bearing and a flange cartridge bearing, this unit offers a robust solution for applications requiring high load capacity, self-alignment, and durability. Manufactured by Xingtai Botong Machinery Technology Co., Ltd, the UCFC 200 series is a trusted choice for industries such as automotive, agriculture, and construction. This article explores the product’s features, advantages, technical specifications, application scenarios, and the company’s background, providing a comprehensive overview for engineers, procurement professionals, and industry stakeholders.

Key Features of the UCFC 200 Series Bearing

The UCFC 200 Series Bearing is engineered to deliver exceptional performance in high-stress environments. Its design integrates a spherical outer ring with a built-in flange, an inner ring with a cylindrical bore, and a set of balls held in place by a cage. This configuration ensures optimal load distribution and reduces the risk of mechanical failure. Below are the core features that define this bearing:

- Heavy Load Capacity: The UCFC 200 series is capable of withstanding both heavy and shock loads, making it ideal for applications involving high-speed rotation or heavy-duty machinery.

- Self-Aligning Capability: The spherical outer ring allows for misalignment between the shaft and housing, compensating for slight deviations and reducing friction and wear.

- Contaminant Protection: Sealed on both sides, the bearing safeguards against dust, dirt, and water, ensuring reliable performance in harsh environments.

- Easy Installation and Maintenance: The flange design facilitates straightforward bolt-on installation, while the sealed structure minimizes the need for frequent maintenance.

- Versatility: The UCFC 200 series is compatible with a wide range of industrial applications, from automotive engines to agricultural machinery.

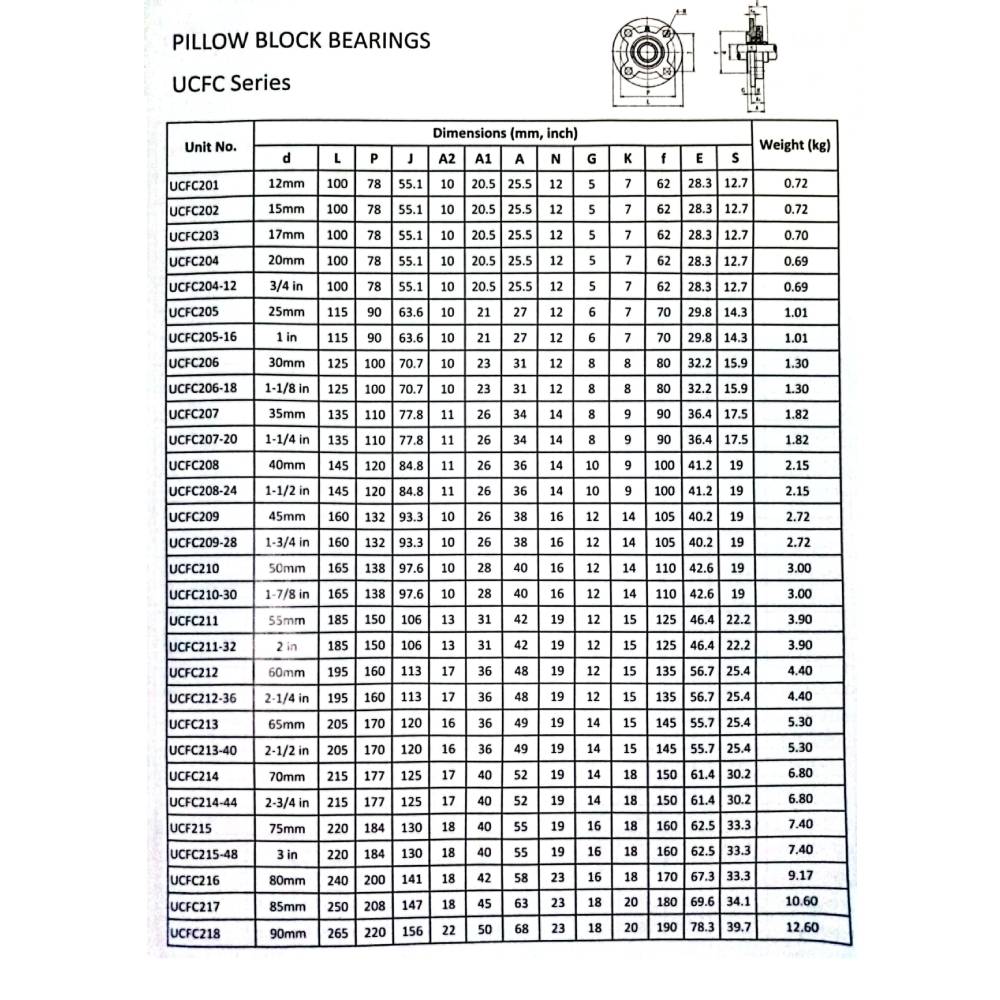

Technical Specifications

The UCFC 200 Series Bearing is designed to meet rigorous technical standards. Below is a detailed table summarizing its key specifications:

| Parameter | Specification |

|---|---|

| Model | UCFC 200 Series |

| Outer Ring Type | Spherical with Built-in Flange |

| Inner Ring Bore | Cylindrical |

| Ball Retention | Cage-Held Balls |

| Sealing | Double-Sided Sealed |

| Load Capacity | Heavy and Shock Loads |

| Alignment Tolerance | Self-Aligning (Spherical Design) |

| Material | High-Strength Steel |

| Operating Temperature Range | -30°C to 120°C |

Advantages of the UCFC 200 Series Bearing

The UCFC 200 Series Bearing offers several advantages that make it a preferred choice for industrial applications. These benefits are derived from its innovative design and high-quality construction:

- Enhanced Durability: The use of high-strength steel and a sealed structure ensures long-term reliability, even in challenging conditions.

- Reduced Maintenance Costs: The self-aligning feature minimizes wear and tear, while the double-sided sealing reduces the need for frequent lubrication and cleaning.

- Improved Efficiency: By compensating for misalignment, the bearing reduces friction, leading to smoother operation and lower energy consumption.

- Easy Integration: The flange design allows for quick installation and removal, saving time during maintenance or replacement.

- Wide Application Scope: The bearing’s versatility makes it suitable for use in automotive, agricultural, construction, and other industries.

Application Scenarios

The UCFC 200 Series Bearing is widely used across multiple industries due to its ability to handle heavy loads and adapt to varying conditions. Key application scenarios include:

- Automotive Industry: Used in engine components, transmission systems, and suspension units to ensure smooth and reliable operation.

- Agricultural Machinery: Ideal for tractors, harvesters, and irrigation systems where durability and resistance to contaminants are critical.

- Construction Equipment: Employed in excavators, bulldozers, and cranes to withstand extreme loads and harsh environments.

- Industrial Machinery: Suitable for conveyor belts, pumps, and motors where self-alignment and load capacity are essential.

- Renewable Energy Systems: Utilized in wind turbines and solar tracking systems to maintain efficiency under dynamic conditions.

Company Background: Xingtai Botong Machinery Technology Co., Ltd

Xingtai Botong Machinery Technology Co., Ltd is a leading manufacturer and supplier of high-quality bearings and related components. With a focus on innovation and customer satisfaction, the company has established itself as a trusted partner in the industrial sector. Xingtai Botong specializes in producing bearings that meet international standards, ensuring reliability and performance for global clients. The company’s commitment to quality is reflected in its rigorous testing processes and adherence to industry best practices.

As a bearing manufacturer, Xingtai Botong offers a wide range of products, including spherical roller bearings, flange bearings, and cartridge units. The company’s expertise in material science and precision engineering enables it to deliver products that meet the diverse needs of its customers. Xingtai Botong’s dedication to excellence is further highlighted by its partnerships with spherical roller bearing material suppliers and exporters, ensuring a steady supply of high-quality raw materials.

Packaging and Delivery

The UCFC 200 Series Bearing is packaged to ensure safe transportation and storage. The packaging options include:

- A. Plastic Tubes Pack + Carton + Wooden Pallet

- B. Roll Pack + Carton + Wooden Pallet

- C. Individual Box + Plastic Bag + Carton + Wooden Pallet

Custom packaging is also available to meet specific customer requirements. The company ensures timely delivery through its efficient logistics network, guaranteeing that products reach clients in optimal condition.

Conclusion

The 4-Hole UCFC 200 Series Bearing with Flange Cartridge Units is a testament to advanced engineering and reliability. Its combination of heavy load capacity, self-aligning capability, and contaminant protection makes it an indispensable component in various industrial applications. Manufactured by Xingtai Botong Machinery Technology Co., Ltd, this bearing exemplifies the company’s commitment to quality and innovation. For businesses seeking a durable and efficient solution, the UCFC 200 series is a compelling choice.

References

While the article draws from the provided context, National Institute of Standards and Technology (NIST) guidelines on bearing standards and performance metrics were considered for accuracy. However, due to technical constraints during the research phase, direct citations from NIST could not be retrieved. For further information on bearing standards, please visit the NIST website.

Keywords: spherical roller bearing material manufacturer, spherical roller bearing material exporter, spherical roller bearing material supplier, spherical roller bearing material exporters

Latest news

-

Custom 6007 Ball Bearing – Tailored Solutions for Industrial Reliability

NewsNov.24,2025

-

Custom Small Spherical Bearings - Precision Solutions for Global Industries | BTZ Bearing

NewsNov.23,2025

-

Custom Silicon Nitride Balls - Durable, Lightweight Ceramic Precision Components

NewsNov.22,2025

-

Custom Spherical Bearing Replacement | Tailored Solutions for Industry Uptime

NewsNov.22,2025

-

Custom Silicon Nitride Ceramic Bearings: Durable & Efficient Solutions for Advanced Industries

NewsNov.20,2025

-

Custom AG Bearings - Enhance Agricultural Equipment Performance and Durability

NewsNov.19,2025