Mar . 12, 2024 19:09 Back to list

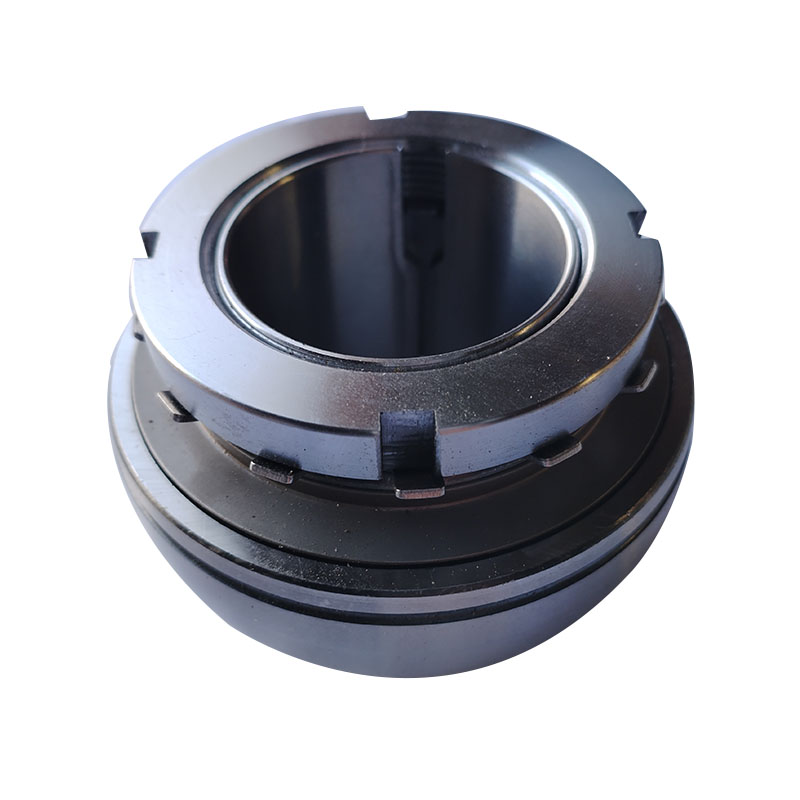

Zirconium Oxide Bearings

Custom zirconium oxide bearings are designed with precision to excel in environments where standard bearings may fall short. Unlike off-the-shelf bearings, which may not be optimized for specific operating conditions, these bearings are tailored to meet the precise needs of the equipment they support.

Manufacturers employ advanced materials and manufacturing techniques to produce custom zirconium oxide bearings of unparalleled quality. Zirconium oxide, also known as zirconia, is chosen for its exceptional hardness, wear resistance, and corrosion resistance, making it ideal for demanding applications.

The applications of custom zirconium oxide bearings are diverse and far-reaching, spanning industries such as aerospace, medical technology, and semiconductor manufacturing. In aerospace applications, these bearings provide critical support for flight control systems and engine components, ensuring precision and reliability in extreme environments. Similarly, in medical devices such as surgical instruments and imaging equipment, custom zirconium oxide bearings deliver exceptional performance and longevity.

As technology continues to advance, so does the evolution of custom zirconium oxide bearings. Manufacturers are constantly innovating to enhance performance and efficiency. From the development of advanced materials to the integration of precision machining techniques, the future of custom zirconium oxide bearings holds exciting possibilities.

Customization remains a key aspect of bearing design, allowing engineers to tailor bearings to specific applications and operating conditions. Whether optimizing load capacity for high-speed machinery or enhancing corrosion resistance for harsh environments, custom zirconium oxide bearings offer endless opportunities for customization.

In conclusion, custom zirconium oxide bearings represent the pinnacle of engineering excellence in the realm of precision machinery. Their ability to withstand extreme conditions, provide essential support, and deliver reliable performance makes them indispensable components for a wide range of applications. As technology continues to advance, these bearings will remain essential assets, driving innovation and reliability in various industries.

Latest news

-

25x52x44.4mm UEL205 Bearing with Eccentric Sleeve

NewsAug.19,2025

-

High Quality 6319 2RS Deep Groove Ball Bearing 95x200x45

NewsAug.18,2025

-

UCT205-15 Take Up Housing Pillow Block Bearing | Reliable

NewsAug.17,2025

-

CKZ-A Sprag Type Freewheels One Way Clutch - High Performance & Reliable

NewsAug.16,2025

-

ASNU 12-35 NFS TFS Roller Freewheel One Way Clutch Bearings

NewsAug.15,2025

-

Durable AK208 Pillow Block Housing | Reliable Bearing Support

NewsAug.14,2025