May . 06, 2024 15:59 Back to list

Basic Knowledge of Deep Groove Ball Bearings

Basic Knowledge of Deep Groove Ball Bearings

Basic parameters of deep groove ball bearings:

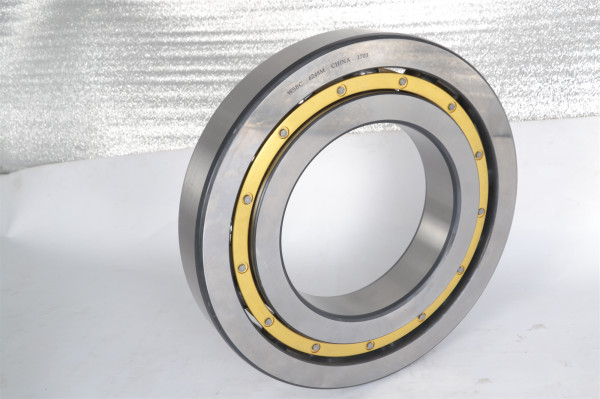

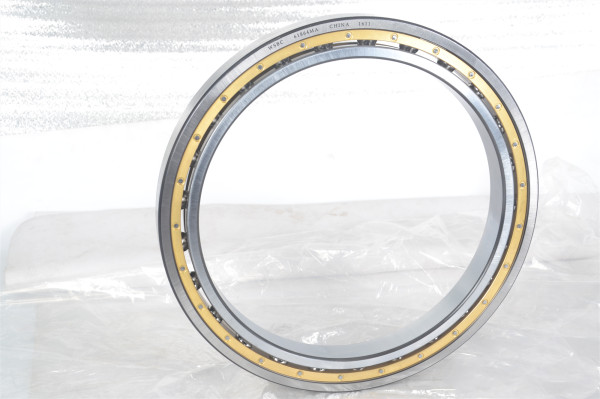

Deep groove ball bearings are the most common type of rolling bearing. The basic deep groove ball bearing consists of an outer ring, an inner ring, a set of steel balls, and a set of cages. There are two types of deep groove ball bearings: single-row and double-row. The deep groove ball structure is also divided into two types: sealed and open. And oil-proof seal type. The cover material of the dust-proof and sealed deep groove ball is stamped with a steel plate, which only serves to prevent dust from entering the bearing raceway. The oil-proof deep groove ball bearing is a contact oil seal, which can effectively prevent the grease in the bearing from overflowing. The single row deep groove ball bearing is coded as 6, and the double row deep groove ball bearing is coded as 4. Its simple structure and convenient use make it the most popular and widely used bearing.

Working principle of deep groove ball bearings

Deep groove ball bearings mainly bear radial load, and can also carry radial load and axial load at the same time. When it is only subjected to radial loads, the contact angle is zero. When a deep groove ball bearing has an ample radial clearance, it has the performance of an angular contact bearing and can withstand a large axial load. The deep groove ball bearing has a small friction coefficient and a high limit speed.

Characteristics of deep groove ball bearings

Deep groove ball bearings are the most commonly used rolling bearings. Its structure is simple and easy to use. It is mainly used to bear radial loads, but when the bearing radial clearance is increased, it has an absolute angular contact ball bearing performance and can carry combined radial and axial loads. It can also be used to take the pure axial load when the speed is high, and the thrust ball bearing is not suitable. Compared with other types of bearings with the same specifications as deep groove ball bearings, this type of bearing has a small friction coefficient and high limiting speed. But it is not resistant to impact and is not suitable for heavy loads.

After the deep groove ball bearing is installed on the shaft, the axial displacement of the rod or the housing can be limited in the axial clearance of the bearing so that it can be axially positioned in both directions. In addition, this type of bearing also has a specific self-aligning ability. When it is inclined 2 ′ to 10 ′ relatives to the housing hole, it can still work usually, but it has a particular impact on the bearing life.

20*47*14mm 6204-2RS C3 Deep Groove Ball Bearing

Structure of deep groove ball bearings

Deep groove ball bearings have a simple structure and are easy to achieve higher manufacturing accuracy than other types, so they are convenient for mass production in series, the manufacturing cost is low, and they are ubiquitous. In addition to the primary model, deep groove ball bearings have various modified structures, such as deep groove ball bearings with dust cover, deep groove ball bearings with rubber seals, deep groove ball bearings with retaining grooves, and Deep groove ball bearing with ball notch and large load capacity, double row deep groove ball bearing.

Deep groove ball bearing installation method:

1. Method 1: Press-fit

The inner ring of the bearing and the shaft are tightly fitted. When the outer ring and the bearing seat hole are loosely fitted, the bearing can be press-fitted on the pole with a press, and then the shaft and the bearing are inserted into the bearing seat hole. On the end face of the bearing inner ring, a soft metal material assembly sleeve (copper or mild steel) is cushioned. The outer bearing ring is tightly fitted with the bearing seat hole. When the inner circle and the shaft are loosely fitted, the bearing can be pressed into the bearing first. In the seat hole, the outer diameter of the mounting sleeve should be slightly smaller than the width of the seat hole. If the bearing ring is tightly fitted with the shaft and the seat hole, the inner and outer rings must be pressed into the shaft and the seat hole at the same time. The structure of the mounting sleeve should be able to tighten the end faces of the bearing inner ring and outer ring at the same time.

2. Method 2: Heating

By heating the bearing or bearing seat, the thermal expansion is used to convert the tight fit into a loose fit. It is a commonly used and labor-saving installation method. This method is suitable for the installation of bearings with a large interference amount. The ferrule of the separable bearing is put into the oil tank and heated evenly at 80-100 ℃, and then it is taken out of the oil and installed on the shaft as soon as possible. Axial tightening. When the outer bearing ring is tightly matched with a light metal bearing seat, a hot mounting method using a heated bearing seat can be used to prevent the mating surface from being scratched. When heating the bearing with an oil tank, a grid should be placed at a certain distance from the bottom of the tank, or the bearing should be hung with a hook. The bearing cannot be placed on the bottom of the tank to prevent impurities from entering the bearing or uneven heating. There must be a thermometer in the tank. Strictly control the oil temperature not to exceed 100 ℃ to prevent the tempering effect and reduce the hardness of the ferrule.

Latest news

-

25x52x44.4mm UEL205 Bearing with Eccentric Sleeve

NewsAug.19,2025

-

High Quality 6319 2RS Deep Groove Ball Bearing 95x200x45

NewsAug.18,2025

-

UCT205-15 Take Up Housing Pillow Block Bearing | Reliable

NewsAug.17,2025

-

CKZ-A Sprag Type Freewheels One Way Clutch - High Performance & Reliable

NewsAug.16,2025

-

ASNU 12-35 NFS TFS Roller Freewheel One Way Clutch Bearings

NewsAug.15,2025

-

Durable AK208 Pillow Block Housing | Reliable Bearing Support

NewsAug.14,2025