Feb . 21, 2024 15:55 Back to list

What is a Spherical Bearing?

Industrial bearings are essential in industrial machinery, enabling smooth operation and reducing wear for prolonged equipment life. There exists a wide array of bearing types, each designed for specific roles and load requirements. Spherical bearings have carved out a niche of particular importance. Designed to accommodate a wide range of motion and angles, these bearings provide solutions to some of the most challenging aspects of mechanical engineering. This blog post will provide a focused overview of spherical bearings, highlighting their unique design and application in modern industry.

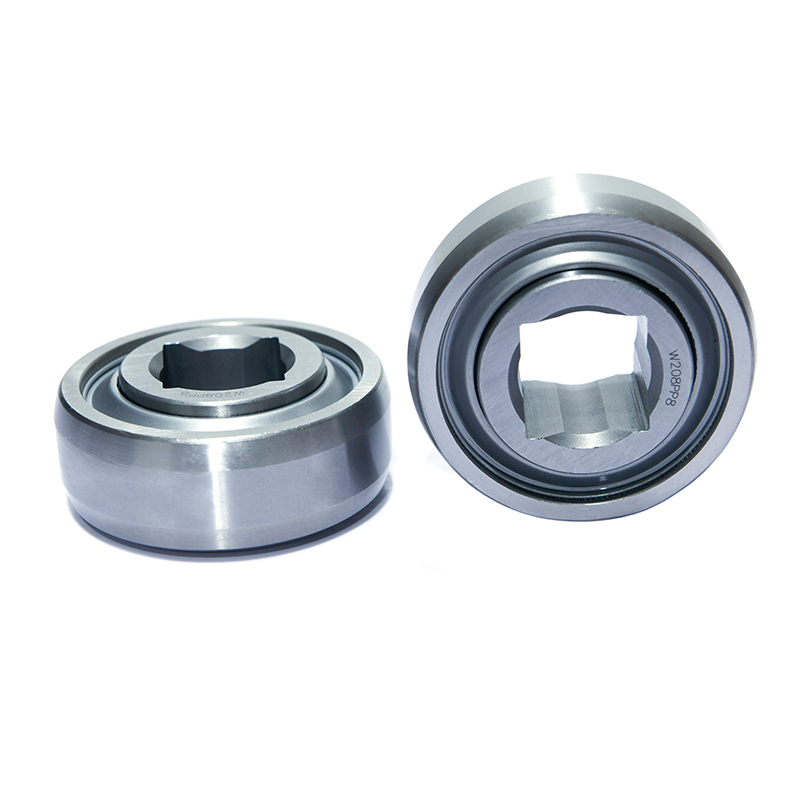

Square Bore W208PP8 Disc Harrow BearingT

Understanding Spherical Bearings

Spherical bearings, also known as spherical plain bearings, are a type of plain bearing that deal with angular motion (oscillating movements) at the interface between two components.

Design and Components

- Inner Ring: This is the part of the bearing that typically mounts onto a shaft and has a spherically convex outer surface.

- Outer Ring: This ring mounts into a housing and has a concave inner surface that is spherically shaped to match the outer surface of the inner ring.

- Sliding Contact: The bearing operates via sliding motion between the inner and outer rings, not rolling elements like ball bearings or roller bearings.

Features

- Self-aligning: Their design allows for self-alignment, which can accommodate shaft misalignment and mounting inaccuracies.

- Angular Rotation: They can facilitate angular rotation in a wide range of movement and are commonly used in applications that require oscillation or tilting movements.

- Load Capacity: Spherical plain bearings typically handle high radial loads but can also support certain levels of axial loads.

Types of Spherical Bearings

Depending on the application and requirements such as load capacity, self-lubrication, and maintenance, spherical plain bearings come in various types:

- Metal-on-Metal: These require regular lubrication and are durable for high-load and high-impact applications.

- Composite Material: Bearings with composite materials like PTFE liners can provide self-lubrication and are maintenance-free.

- Sealed Bearings: Some spherical plain bearings have seals to protect against contaminants and to retain lubrication.

Applications

Spherical bearings are used in applications that involve oscillating, rotating, and aligning movements, such as:

- Vehicle Suspensions: To accommodate changing load and road conditions while allowing for the misalignment between parts.

- Heavy Equipment: For articulating joints in construction, mining, and agricultural machinery.

- Hydraulic Cylinders: Acting as pivot points.

- Linkages: In industrial machines, aircraft control linkages, and marine applications for smooth articulation and movement.

When selecting a spherical plain bearing for an application, considerations such as load ratings, the range of motion, environmental conditions, and required lifespan are all important to ensure the correct bearing is chosen for the specific requirements.

What are Spherical Roller Bearings?

Spherical roller bearings are a type of rolling-element bearing that allow for angular misalignment and are designed to manage high radial loads, as well as moderate axial loads in both directions. These bearings have two rows of rollers, a common sphered outer ring raceway, and two inner ring raceways inclined at an angle to the bearing axis, offering excellent performance in situations where there may be shaft deflections or misalignment.

Types of Spherical Roller Bearings

The types of spherical roller bearings are mainly distinguished by whether they are sealed or non-sealed:

- Non-sealed/Open Bearings: These bearings do not have seals and rely on a clearance between the bearing components to permit the entry and exit of lubricant, allowing them to operate at higher speeds and temperatures. They are typically used in environments where they can be maintained and cleaned in place, such as in heavy-duty machinery and processing equipment.

- Sealed Spherical Roller Bearings: Sealed bearings come with inbuilt seals to keep lubricant in and contaminants out. This enhances bearing life and performance, especially in environments exposed to dust, moisture, and other potential contaminants. Sealed spherical roller bearings require less maintenance and can often be considered for more challenging environments.

Importance of Choosing the Right Type

Choosing the right type of spherical roller bearing is crucial as it directly impacts the efficiency and longevity of the machinery. The correct selection must take into account factors like load capacities, rotational speeds, and the operational environment.

Non-sealed bearings might be chosen for high-speed applications where maintenance is possible, while sealed bearings would be more appropriate for difficult, contaminant-prone conditions where minimal maintenance is desired.

Hence, understanding the operational demands and conditions is key to selecting a bearing that will offer optimal performance and reliability.

Benefits of Spherical Roller Bearings

Spherical roller bearings offer numerous advantages:

- Reduced Friction and Smooth Rotation: Minimizing energy loss and enhancing operational efficiency.

- Angular Misalignment Tolerance: Capable of adjusting to alignment errors which are common in heavy-duty applications.

- Support for Rotating Axle: Delivering sturdy support for shafts and axles under heavy loads.

- Outstanding Load-carrying Capacity: Engineered to handle heavy radial and axial loads simultaneously.

- Moderate to High-speed Capability: Suited for a broad range of rotational speeds.

- Reduced Maintenance Requirements: Especially sealed versions which don't require regular lubrication.

- Extended Service Life: Long-lasting performance due to their robust construction.

- Reduced Noise and Vibration Levels: Enhancing the comfort and safety of machinery operation.

Applications of Spherical Roller Bearings

These bearings excel under the following conditions:

- Tough Operating Conditions: Ideal for environments with heavy loads, high speeds, and potential misalignment, these bearings maintain performance in demanding situations.

- Misalignment Applications: They compensate for angular misalignments, handling combined radial and axial loads effectively.

- Mechanical Uses: Spherical roller bearings are critical in various machines for their durability and self-aligning properties.

Industry Use Cases

Mining and Construction Equipment: Where high load and vibration are common.

- Textile Machinery: Where precision and reliability are key.

- Off-road Vehicles: Where reliability in rugged environments is crucial.

- Pumps and Mechanical Fans: Where steady and reliable rotation is essential.

- Marine Propulsion and Wind Turbines: Where varying loads and speeds are managed.

- Gearboxes: Where they manage the interface between different moving components.

Spherical Roller Bearings: Enhancing Performance

Beyond their specific advantages, spherical roller bearings contribute to overall machinery performance by:

- Friction and Noise Reduction: These bearings are precisely engineered to minimize friction, thereby enhancing machinery efficiency while concurrently reducing acoustic emissions.

- Angular Misalignment Tolerance: They are adept at handling misalignment between the shaft and housing, which is essential for optimal performance and reducing stress on the system.

- Read bearing shaft quality to learn more about shaft-related things.

- Reliability and Longevity: Spherical roller bearings are synonymous with high reliability, capable of withstanding substantial loads, which extends their operational lifespan and minimizes maintenance requirements.

Spherical Bearings Vs Spherical Roller Bearings

|

Feature |

Spherical Bearings (Plain) |

Spherical Roller Bearings |

|

Design |

Consist of an inner and outer ring with a spherical sliding contact surface. |

Comprise inner and outer rings with a spherical raceway, and spherical rolling elements (rollers). |

|

Rolling Elements |

None. Operate on sliding motion. |

Yes. Contain rollers that facilitate rolling motion. |

|

Load Capacity |

High radial load capacity; moderate axial load capacity. |

Very high radial and axial load capacities due to rolling elements. |

|

Misalignment Accommodation |

Excellent. Designed to accommodate high degrees of misalignment. |

Good. Can accommodate misalignment but to a lesser degree than spherical plain bearings. |

|

Speed |

Generally suited for lower speeds due to sliding contact. |

Can handle higher speeds, suitable for applications involving rotation. |

|

Lubrication |

Can be maintenance-free (self-lubricating) or require lubrication. |

Typically require lubrication to facilitate roller movement and reduce wear. |

|

Sealing |

May come with seals to protect from contaminants or without seals. |

Usually sealed to protect the rolling elements and raceway from contamination. |

|

Application Examples |

Hydraulic cylinders, articulating joints, suspension systems. |

Gearboxes, conveyors, pumps, fans, and industrial machinery. |

|

Angular Movement |

Primarily designed to handle oscillating and pivoting motion. |

Primarily designed to handle rotation with some capacity for misalignment. |

|

Typical Materials |

Steel, bronze, with or without composite liners like PTFE. |

Hardened steel, sometimes with surface treatments or coatings for durability. |

Conclusion

From the initial query of "what is a spherical bearing" to understanding the intricacies of spherical roller bearings, it's clear these components are vital to industrial machinery. The selection of the right bearing is paramount for ensuring optimal functionality and longevity. Our experts at Lily Bearing can guide you through the selection process, offering customization and manufacturing solutions tailored to your needs. Reach out to discover how we can enhance your machinery's performance with the right bearing solutions.

Latest news

-

Durable PLC 110-190 Spherical Roller Bearing for Mixer Reducer

NewsAug.26,2025

-

CSK-2RS Sprag Clutch One Way Bearing: Sealed, High Torque, Durable

NewsAug.25,2025

-

CKZ-D Series One Way Overrunning Clutch: Reliable Power Control

NewsAug.24,2025

-

203KRR3 Round Bore Series Bearings | Cylindrical Outer Ring, Precision

NewsAug.23,2025

-

Top Spherical Roller Bearing Material Exporter - High Performance

NewsAug.22,2025

-

Durable UCFC202-09 Round Flange Housing 4-Bolt Ball Bearing

NewsAug.21,2025