What are Bearings?

Bearings are mechanical components designed to reduce friction between moving parts and to support and guide rotational or linear motion. On a bicycle, bearings are used in wheel hubs, bottom brackets, headsets, jockey wheels, and suspension forks.

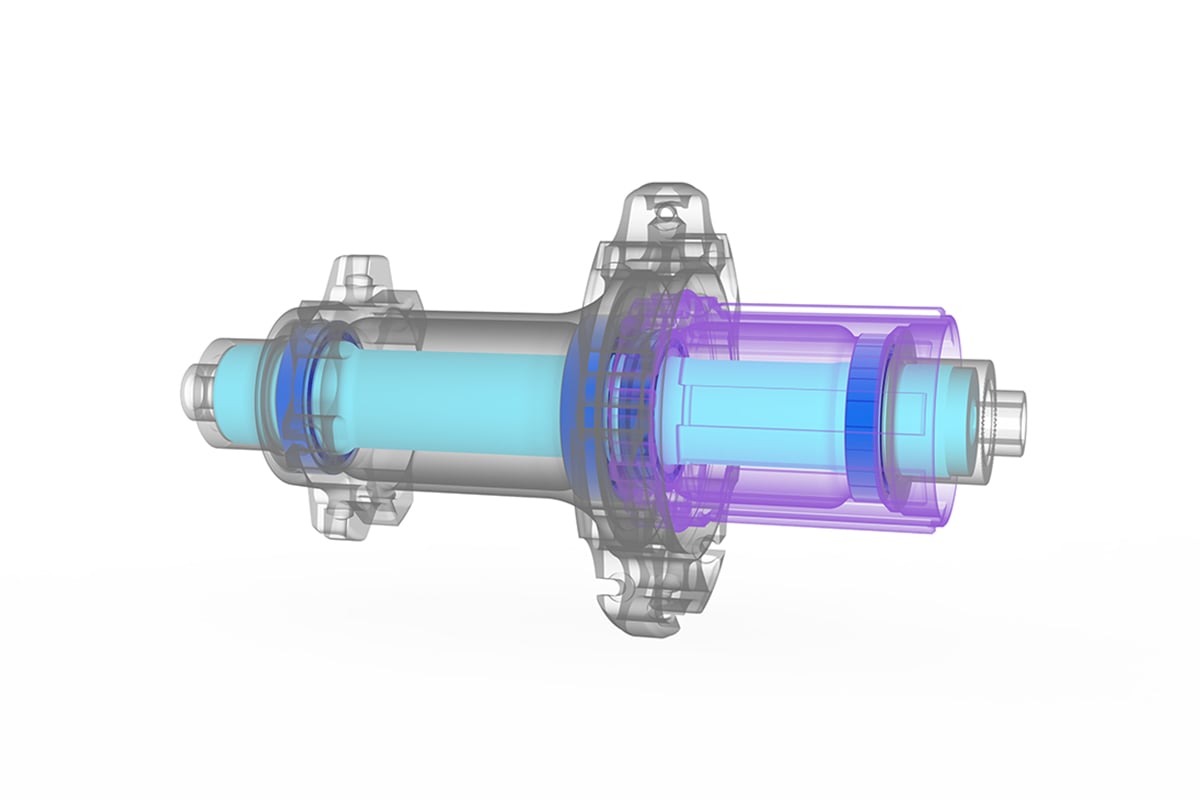

Sealed Cartridge Bearings

In our wheels, we use sealed cartridge bearings. This type of bearing consists of bearing components are enclosed within a sealed, self-contained unit.It features four main components. The advantages of sealed cartridge bearings is that they are sealed to prevent ingress of contaminants, reducing wear and increasing durability. Being self-contained, they are easier to replace and install.

Parts of a Bearing

Inner and Outer Races

These are the rings that house the rolling elements and provide the surfaces on which they roll.

Rolling Elements

Rolling elements are the balls or rollers that roll between the inner and outer races to reduce friction.

Cage

A cage keeps the rolling elements evenly spaced and prevents them from contacting each other.

Seals

Seals are protective barriers that enclose the bearing, keeping contaminants out and lubrication in.

About Ceramic Bearings

Ceramic bearings use ceramic balls made of silicon nitride (Si2N4) rather than traditional steel or metal alloy.

The Benefits of Ceramic Bearings

Ceramic bearings have a number of benefits over steel bearings.

Weight

Ceramic balls can be significantly lighter than steel ones, up to 50% lighter. This contributes to lighter sealed cartridge bearings. While ceramic balls make for a relatively small weight saving, its can add up since each wheelset requires six cartridge ball bearings. Using ceramic bearings is one of the reasons why our wheels can be made lighter than the competition.

Rolling Resistance

Ceramic bearings can be made more spherical and offer lower rolling resistance as compared to steel bearings all things being equal. As a result, they can carry heavier rider loads without stressing the balls or races, while using less lubrication. This means you can roll faster.

Thermal Expansion

Ceramic ball bearings do not suffer thermal expansion like steel bearings.

Corrosion Resistance

Unlike steel ball bearings, ceramic ones do not rust, allowing them to roll smoothly.

Reduced Wear

They are lighter in weight, more resistant to wear, have lower friction leading to less rolling resistance, more corrosion resistant, and experience less thermal expansion. They are also 30% harder than steel bearings.

Full Ceramic vs. Hybrid Ceramic Bearings

Full Ceramic Bearings

There are two different types of ceramic bearings. A full ceramic bearing has ceramic ball bearings, inner and outer rings/races, and cages. While full ceramic bearings have the lowest rolling resistance, they are more meant for applications in the aerospace, medical equipment, and chemical processing industries. Full ceramic bearings, while the lightest option, are less durable because they are brittle, making them unsuitable for hubs.

Hybrid Ceramic Bearings

The type of bearing that is more commonly found in bicycle hubs is the hybrid ceramic. The rings/races and cage are made of steel, while the balls are ceramic. Hybrid ceramic bearings are used in electric motors, machine tools, and cycling. They offer most of the benefits of ceramic bearings, while also being durable enough to last a long time, even longer than steel bearings in many cases.

Not All Ceramic Bearings are Created Equal

In theory, ceramic bearings should offer lower rolling resistance and an increased lifespan. However, that is not always the case. Bearing brands and different standards can make a big difference. In some cases, ceramic bearings are worse than steel bearing. This is because some brands don’t use high-quality ceramic balls or meet the ISO 9001 manufacturing standards. They may require heavier grease and have poor performance.

Not All Hubs Are Created Equal

Many of the issues riders have with bearings has nothing to do with the bearings. Instead it has to do with machining accuracy of hubs. Lower-end hubs with poorer tolerances can lead to issues, namely damage to the bearings and races. Because we machine our own hubs with 5-axis CNC machines, we are able to manufacture hubs with higher concentricity. The 0.02mm tolerances our CNC machines are capable of, reduce the likelihood of uneven pressure on the bearings, extending their service life while reducing rolling resistance.

As a result of this precision machining, the feedback from tens of thousands of riders using ceramic bearing wheelsets since 2019 has been overwhelmingly positive. The wheels just keep on rolling.