May . 06, 2024 15:49 Back to list

How Do Ball Bearings Work?

How Do Ball Bearings Work?

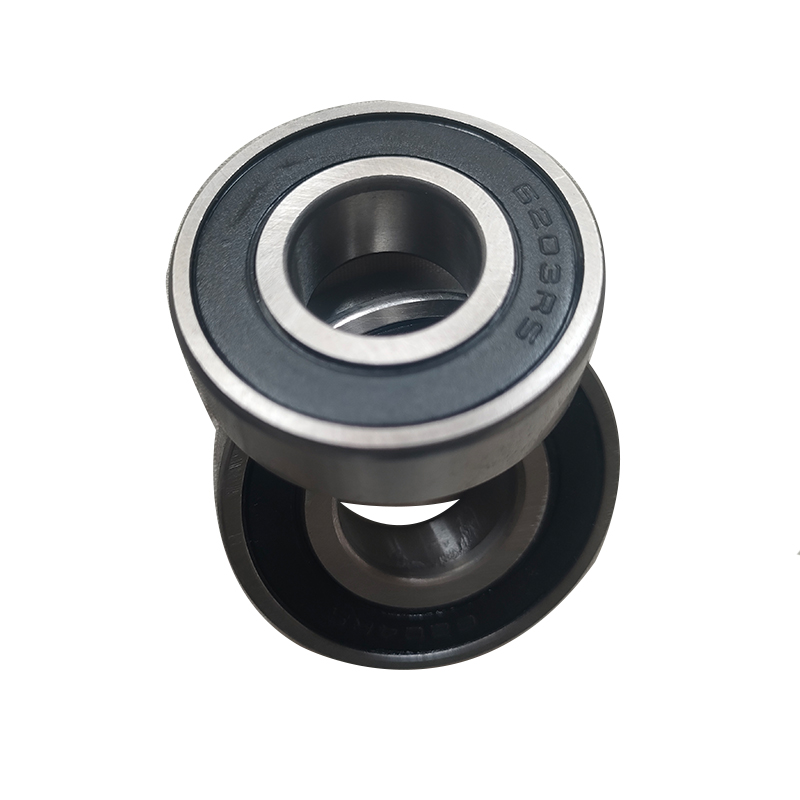

Ball bearings are some of the most commonly used bearings in rotary movement applications. They comprise a row or multiple rows of balls between inner and outer raceways. This design capitalizes on the concept that rolling elements produce less friction than sliding elements. One ring is normally attached to the rotating assembly, or shaft, and as it rotates the balls roll around the inner raceway, while the other ring remains stationary. This allows for rotational movement with an extremely low friction coefficient, making it great for applications with high speeds and low friction requirements.

Bearings typically need to handle two types of loads: thrust loads and radial loads. Thrust loads, also called axial loads, are forces acting parallel to the bearing axis, while radial loads act perpendicular to the bearing axis. Ball bearings can withstand both thrust and radial loads.

However, they have a relatively low load capacity, so they are typically used in applications with lighter load requirements. The spherical roller shape leads to very small contact points between the balls and raceways. This allows for smooth movement, but lowers load capacity abilities. Ball bearings can however accommodate some misalignment of the inner and outer raceway.

Types of Ball Bearings

There are several different designs for these bearings that specialize in different applications:

-

Angular contact: These bearings feature axially asymmetrical raceways. This redistributes radial loads through the bearing, making them great for supporting combined loads, or loads in both axial and radial directions. Larger contact angles generally support higher axial loads and lower radial loads, and the opposite occurs for smaller contact angles.

-

Axial/Thrust: Axial bearings utilize multiple raceways side by side. As the name implies, they are specialized for axial loads; radial loads can cause damage to the bearing by forcing the raceways apart.

- Deep-groove: A unique raceway design allows these bearings to support higher loads than other ball bearings. However, they cannot handle as much misalignment as normal ball bearings.

20*47*14mm 6204-2RS C3 Deep Groove Ball Bearing

Features of Ball Bearings

As with most bearings, ball bearings can have a variety of features that provide different types of support to the bearing performance.

-

Rows: Most bearings are installed in pairs to distribute loads more evenly. Double row bearings have two rows of balls rather than just one, eliminating the need to install multiple bearings. While this provides a cost and space-effective replacement to a pair of single row bearings, they typically require better alignment.

-

Flange: This is a type of bearing housing that can be installed to fix the bearing onto the mounting surface. This simplifies installation and axial location.

-

Cage: Cages secure the balls within the bearing, to keep them in place and reduce friction. They are commonly made of steel or polyamide plastic, depending on the application. While they are cheaper to produce, plastic cages may not be suitable under high temperatures or strenuous environments.

-

Material: Ball bearings are commonly made of stainless steel, chrome steel, or ceramic. Ceramic bearings are normally used in applications with strenuous or challenging conditions, such as underwater or in a vacuum. Ceramic is 40% less dense than steel; these bearings resist corrosion and do not require lubrication, however they are more brittle and able to crack than steel. Hybrid bearings, featuring steel raceways and ceramic balls, are often used to decrease friction. Lighter balls allow for faster spinning and less energy use for rotational movement.

-

Self-Alignment: Self-aligning ball bearings feature an outer ring with a spherical raceway. This allows the bearing to tolerate angular misalignment that could be due to housing or shaft deflections or improper mounting. These bearings typically have a lower load capacity than other ball bearings, and are commonly used in applications with a long shaft such as transmissions or textile factories.

Assembly Types

Ball bearings can be assembled in a multitude of different ways, which impacts the load capacity and performance of the bearing.

- Conrad: Named after its inventor Robert Conrad, this method involves placing the inner ring eccentrically within the outer ring, with a single point of contact. Balls are then inserted opposite the contact point and distributed evenly, which forces the rings into proper position. Usually a cage is installed as well to maintain even ball distribution. A limited number of balls can be inserted in this assembly method, which limits the load capacity of the bearing.

- Slot fill: In this assembly method, both raceways feature notches so the balls can be slipped into place. This allows for any number of balls to be inserted, resulting in higher radial load capacity. These bearings, however, have lower axial load capacity, as the notches in the raceways lead to a discontinuity in the rings that can impact bearing strength.

- Relieved race: In this construction, either the outer diameter of the inner ring or the inner diameter of the outer ring is altered to produce a larger space to insert the balls. This also allows for any number of balls to be inserted, however bearings with this assembly method can only support axial loads in the direction away from the relieved race.

- Fractured race: One of the rings is sliced completely through to allow for ball insertion, and then re-assembled. A pair of steel bands is used to support the fractured sections during bearing alignment. This method also allows for any number of balls, and can support axial loads in either direction.

Latest news

-

Durable PLC 110-190 Spherical Roller Bearing for Mixer Reducer

NewsAug.26,2025

-

CSK-2RS Sprag Clutch One Way Bearing: Sealed, High Torque, Durable

NewsAug.25,2025

-

CKZ-D Series One Way Overrunning Clutch: Reliable Power Control

NewsAug.24,2025

-

203KRR3 Round Bore Series Bearings | Cylindrical Outer Ring, Precision

NewsAug.23,2025

-

Top Spherical Roller Bearing Material Exporter - High Performance

NewsAug.22,2025

-

Durable UCFC202-09 Round Flange Housing 4-Bolt Ball Bearing

NewsAug.21,2025