Feb . 21, 2024 16:49 Back to list

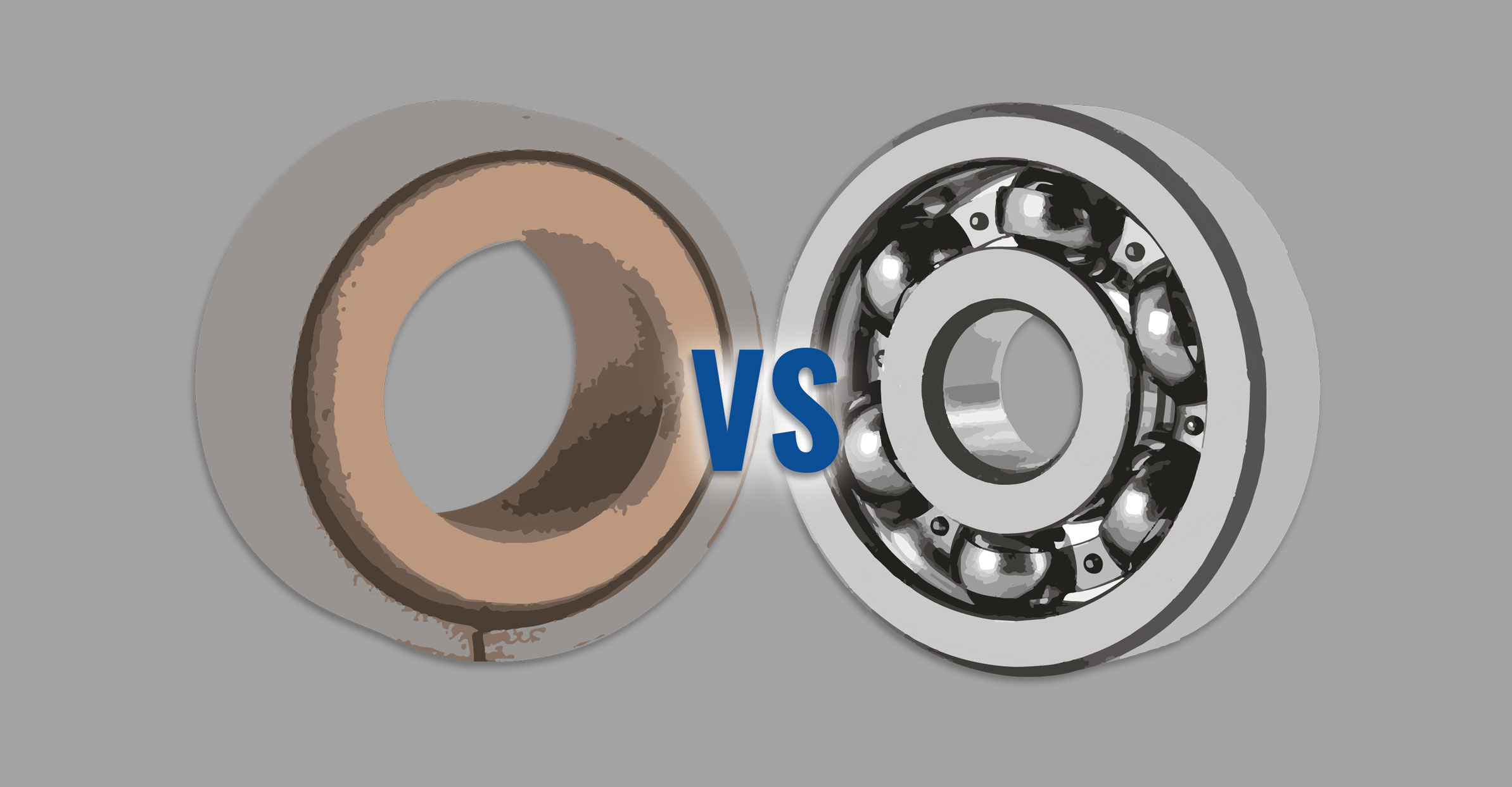

SPHERICAL PLAIN BEARINGS VS. BALL BEARINGS

Sometimes there can be questioning to what is the best type of bearing for your application. Most of the time ball bearings become the go-to product, but make sure you are assessing all of the advantages and disadvantages. On some applications, a spherical plain bearing could be the best fit for your solution.

Sometimes there can be questioning to what is the best type of bearing for your application. Below is an infographic highlighting 7 benefits of Triangle's spherical plain bearings. Most of the time ball bearings become the go-to product, but make sure you are assessing all of the advantages and disadvantages. On some applications, a spherical plain bearing could be the best fit for your solution.

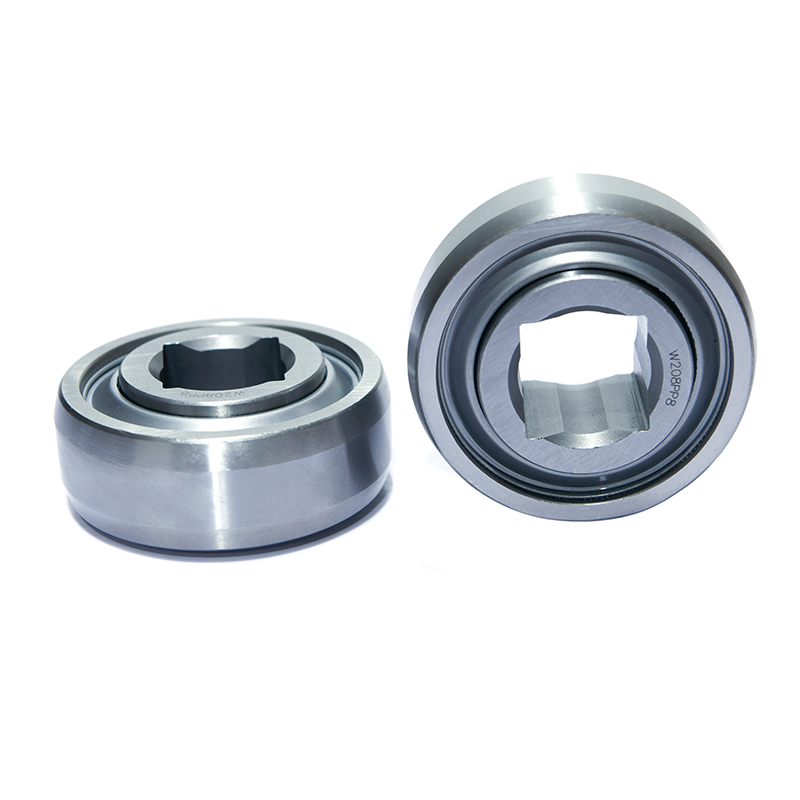

Square Bore W208PP8 Disc Harrow BearingT

7 ADVANTAGES OF TRIANGLE'S SPHERICAL PLAIN BEARINGS

1. Achieve self-alignment without the added cost

Ball bearings are offered and designed with self-aligning elements, but these bearings are less available and are more costly. If there happens to be a misalignment during assembly, self-aligning plain bearings can compensate for the problem without the added cost. Triangle's self-aligning plain bearings keep mount assemblies aligned which reduces costly methods of fixing the error by reducing time and possible machining fixes.

2. Low maintenance

Triangle's spherical plain bearings are sintered. Sintered bearings consist of pressed metal powder with pores that are impregnated with oil. This results in permanent lubrication which makes Triangle's bearings low maintenance.

3. Quiet operation

Because Triangle's spherical plain bearings are permanently lubricated, this results in a quieter operation.

4. Dirt resistant

During operation, the bore of the bearings is heated up which makes the oil seep out of the pores. This is an advantage because if your application is in a dusty environment, the oil will push the dirt out.

5. Reduce damage

Supporting a motor shaft with a bearing example: If a spherical plain bearing fails, it will make a squeaking noise, but the motor will keep running. If a ball bearing fails, it could easily lock up the shaft ruining the motor. In other cases, different components could be damaged.

6. Custom sizes

Custom spherical plain bearings are available with minimal added cost (at OEM quantities) due to the manufacturing process of sintered bearings. Ball bearings are more complex and it is more costly to make a small adjustment.

7. Take up less space

Spherical plain bearings take up less space and can be mounted in tight areas where a ball bearing may not fit.

Latest news

-

CKZ-A Sprag Type Freewheels One Way Clutch - High Performance & Reliable

NewsAug.16,2025

-

ASNU 12-35 NFS TFS Roller Freewheel One Way Clutch Bearings

NewsAug.15,2025

-

Durable AK208 Pillow Block Housing | Reliable Bearing Support

NewsAug.14,2025

-

28.6x80x36.53mm W208PPB5 Heavy Duty Disc Harrow Bearing

NewsAug.13,2025

-

CKZF-B Series Flywheel Backstop Clutch: Reliable Reverse Prevention

NewsAug.12,2025

-

W210PPB6 PEER Square Bore Farm Bearings - Heavy-Duty & Durable

NewsAug.11,2025