Apr . 01, 2024 15:57 Back to list

The Secrets of Motor Bearings: Types, Costs, and Replacement

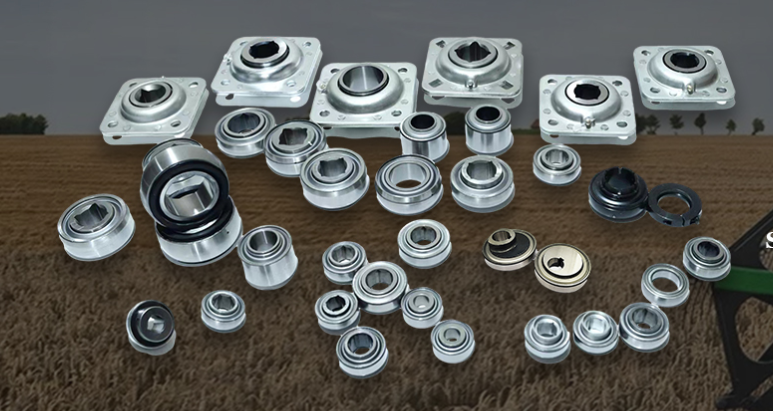

Motor bearings are crucial components in electric motors, providing support and facilitating smooth rotation of the shaft. They come in various types, materials, and sizes, each designed for specific applications. Let's explore the types of motor bearings, their costs, and the process of replacing them.

Motor Bearing Types

Ball Bearings: These are the most common type of bearings used in electric motors. They consist of steel balls housed between two rings, providing smooth rotation and low friction.

Spherical roller bearing: Roller bearings use cylindrical or tapered rollers instead of balls. They are capable of handling heavier loads and higher speeds compared to ball bearings.

Sleeve Bearings: Also known as bushings, sleeve bearings are simple and cost-effective bearings that provide smooth rotation of the shaft.

Thrust Bearings: Thrust bearings are designed to handle axial loads exerted on the motor shaft, ensuring stability and proper alignment.

Ceramic Bearings: Ceramic bearings, made from materials such as silicon nitride or zirconia, offer superior performance in high-speed and high-temperature applications.

Motor Bearing Costs

The cost of motor bearings varies depending on factors such as type, size, material, and manufacturer. Generally, ball bearings and roller bearings tend to be more expensive than sleeve bearings due to their precision design and higher load capacity. Ceramic bearings typically have a higher upfront cost but may offer long-term savings due to their durability and performance benefits.

Motor Bearing Replacement

Replacing bearings in an electric motor is a maintenance task that may be necessary to prevent premature failure and prolong the motor's lifespan. The process involves removing the motor housing, disassembling the motor, removing the old bearings, and installing new ones. It's essential to follow the manufacturer's guidelines and use proper tools and techniques to ensure a successful bearing replacement.

Motor Bearing Fitting

Proper fitting of motor bearings is crucial for ensuring optimal performance and longevity. Bearings should be installed with the correct clearance and preload to prevent excessive wear and heat generation. Additionally, ensuring proper alignment and lubrication is essential for minimizing friction and maximizing efficiency.

Motor Bearing Material

Motor bearings are typically made from steel, stainless steel, or ceramic materials. Steel bearings are the most common and cost-effective option, offering good performance in most applications. Stainless steel bearings provide enhanced corrosion resistance, making them suitable for harsh environments. Ceramic bearings offer superior hardness, corrosion resistance, and thermal stability, making them ideal for high-speed and high-temperature applications.

Motor bearings are essential components in electric motors, providing support, stability, and smooth rotation of the shaft. Understanding the different types, costs, and replacement procedures of motor bearings is crucial for ensuring optimal performance and reliability in motor-driven systems.

You can contact us deep groove ball bearing supplier to order the products you need.

Latest news

-

W211PP5 Square Bore Disc Harrow Bearings | Heavy-Duty Sealed

NewsNov.17,2025

-

11018074/82 mm F-801806-PRL steel cage mix reducer bearing

NewsNov.17,2025

-

UCF207-22 4-Bolt Flange Housing Square Bearing Heavy-Duty

NewsNov.17,2025

-

206KRR6-NR 1" Hex Bore Bearing | Sealed, Snap Ring, Ag-Grade

NewsNov.17,2025

-

6303 2RS High Quality Deep Groove Ball Bearing 17X47X14 - C3

NewsNov.10,2025

-

8017058mm 22316 CA Spherical Roller Bearing | High Load

NewsNov.10,2025