Jun . 14, 2024 16:54 Back to list

Spherical sleeve bearings facilitate smooth rotation.

The Significance and Functionality of Spherical Sleeve Bearings

Spherical sleeve bearings, an integral component in various mechanical systems, play a crucial role in ensuring smooth operation and longevity of machinery. These bearings, also known as spherical plain bearings, are designed to accommodate not only radial loads but also thrust and angular misalignments, making them versatile and adaptable to a wide range of applications.

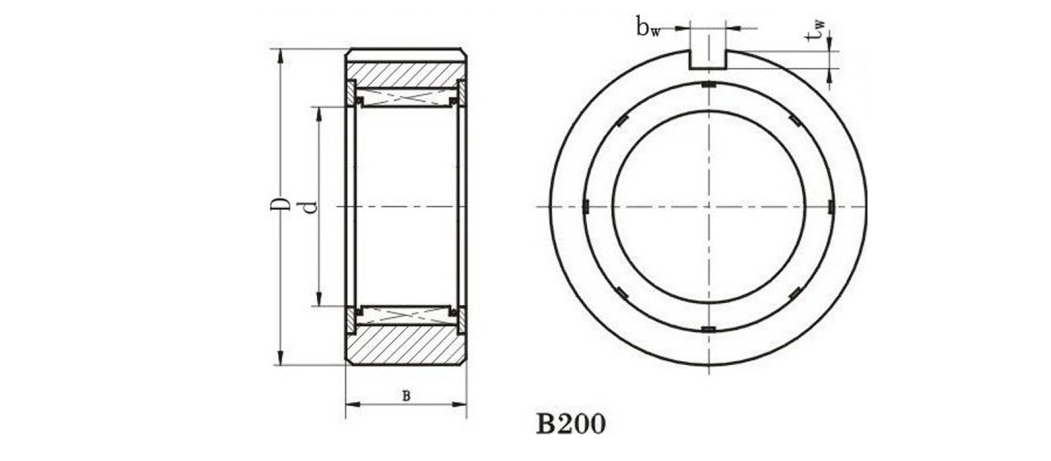

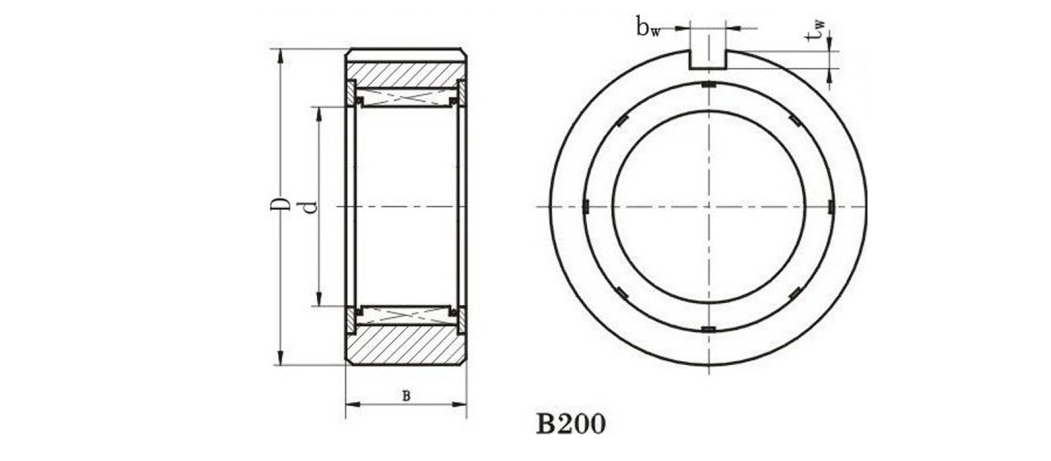

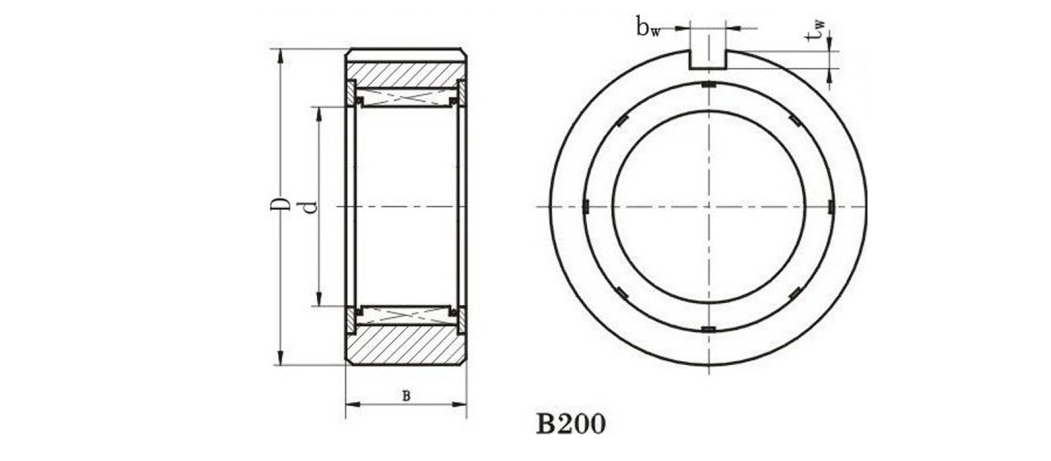

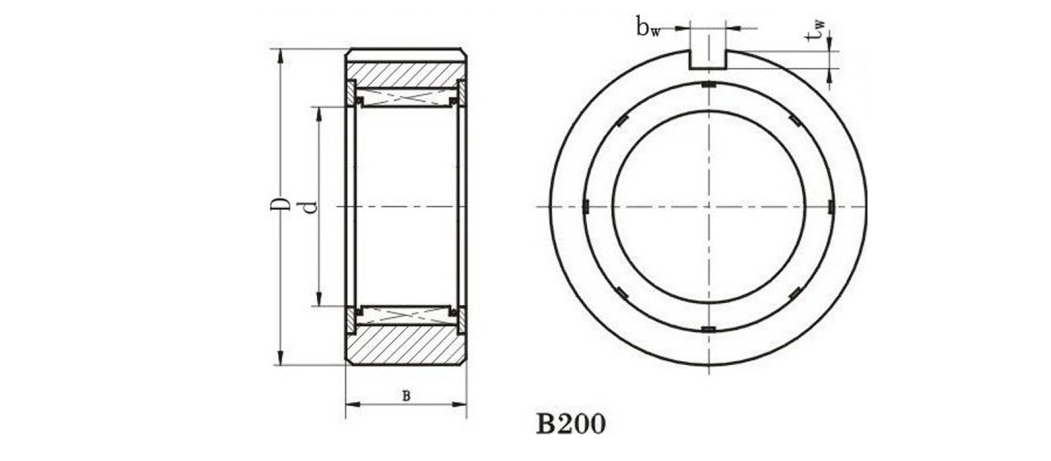

A spherical sleeve bearing, at its core, consists of a cylindrical outer ring with a spherical inner surface and an inner ring or bushing with a matching spherical outer surface. The spherical design allows for a self-aligning capability, which is particularly beneficial in situations where precise alignment is challenging or where the shaft may deflect under load. The bearing's ability to accommodate angular displacement enables it to reduce stress concentrations, thus enhancing overall system durability.

The material composition of spherical sleeve bearings significantly influences their performance. They are typically made from materials like bronze, steel, or polymer, each offering unique advantages. Bronze bearings provide excellent wear resistance and can handle high loads, while polymer bearings offer low friction and are suitable for applications requiring noise reduction or chemical resistance. Steel bearings, on the other hand, offer superior strength and durability.

One of the key benefits of spherical sleeve bearings is their simplicity. They require minimal maintenance, have a relatively low cost, and can operate effectively even in harsh environments They require minimal maintenance, have a relatively low cost, and can operate effectively even in harsh environments They require minimal maintenance, have a relatively low cost, and can operate effectively even in harsh environments They require minimal maintenance, have a relatively low cost, and can operate effectively even in harsh environments

They require minimal maintenance, have a relatively low cost, and can operate effectively even in harsh environments They require minimal maintenance, have a relatively low cost, and can operate effectively even in harsh environments spherical sleeve bearing. They are commonly used in applications such as agricultural equipment, construction machinery, and industrial machinery, where they endure heavy loads and rough operating conditions.

In addition, the self-lubricating properties of certain types of spherical sleeve bearings make them ideal for applications where regular lubrication is difficult or impossible. This feature not only reduces maintenance needs but also extends the bearing's service life.

However, despite their many advantages, spherical sleeve bearings have limitations. They may not be suitable for high-speed applications due to their inherent design, and their load-carrying capacity is generally lower than that of roller or ball bearings. Nonetheless, their versatility, robustness, and ability to handle misalignment make them a preferred choice in numerous engineering designs.

In conclusion, spherical sleeve bearings, with their spherical design and inherent self-aligning capabilities, serve as a vital component in various mechanical systems. Their adaptability, low maintenance requirements, and ability to function in challenging environments make them indispensable in industries ranging from manufacturing to agriculture. As technology advances, the development of more advanced materials and designs will likely further enhance the performance and application scope of these bearings.

spherical sleeve bearing. They are commonly used in applications such as agricultural equipment, construction machinery, and industrial machinery, where they endure heavy loads and rough operating conditions.

In addition, the self-lubricating properties of certain types of spherical sleeve bearings make them ideal for applications where regular lubrication is difficult or impossible. This feature not only reduces maintenance needs but also extends the bearing's service life.

However, despite their many advantages, spherical sleeve bearings have limitations. They may not be suitable for high-speed applications due to their inherent design, and their load-carrying capacity is generally lower than that of roller or ball bearings. Nonetheless, their versatility, robustness, and ability to handle misalignment make them a preferred choice in numerous engineering designs.

In conclusion, spherical sleeve bearings, with their spherical design and inherent self-aligning capabilities, serve as a vital component in various mechanical systems. Their adaptability, low maintenance requirements, and ability to function in challenging environments make them indispensable in industries ranging from manufacturing to agriculture. As technology advances, the development of more advanced materials and designs will likely further enhance the performance and application scope of these bearings.

They require minimal maintenance, have a relatively low cost, and can operate effectively even in harsh environments They require minimal maintenance, have a relatively low cost, and can operate effectively even in harsh environments

They require minimal maintenance, have a relatively low cost, and can operate effectively even in harsh environments They require minimal maintenance, have a relatively low cost, and can operate effectively even in harsh environments spherical sleeve bearing. They are commonly used in applications such as agricultural equipment, construction machinery, and industrial machinery, where they endure heavy loads and rough operating conditions.

In addition, the self-lubricating properties of certain types of spherical sleeve bearings make them ideal for applications where regular lubrication is difficult or impossible. This feature not only reduces maintenance needs but also extends the bearing's service life.

However, despite their many advantages, spherical sleeve bearings have limitations. They may not be suitable for high-speed applications due to their inherent design, and their load-carrying capacity is generally lower than that of roller or ball bearings. Nonetheless, their versatility, robustness, and ability to handle misalignment make them a preferred choice in numerous engineering designs.

In conclusion, spherical sleeve bearings, with their spherical design and inherent self-aligning capabilities, serve as a vital component in various mechanical systems. Their adaptability, low maintenance requirements, and ability to function in challenging environments make them indispensable in industries ranging from manufacturing to agriculture. As technology advances, the development of more advanced materials and designs will likely further enhance the performance and application scope of these bearings.

spherical sleeve bearing. They are commonly used in applications such as agricultural equipment, construction machinery, and industrial machinery, where they endure heavy loads and rough operating conditions.

In addition, the self-lubricating properties of certain types of spherical sleeve bearings make them ideal for applications where regular lubrication is difficult or impossible. This feature not only reduces maintenance needs but also extends the bearing's service life.

However, despite their many advantages, spherical sleeve bearings have limitations. They may not be suitable for high-speed applications due to their inherent design, and their load-carrying capacity is generally lower than that of roller or ball bearings. Nonetheless, their versatility, robustness, and ability to handle misalignment make them a preferred choice in numerous engineering designs.

In conclusion, spherical sleeve bearings, with their spherical design and inherent self-aligning capabilities, serve as a vital component in various mechanical systems. Their adaptability, low maintenance requirements, and ability to function in challenging environments make them indispensable in industries ranging from manufacturing to agriculture. As technology advances, the development of more advanced materials and designs will likely further enhance the performance and application scope of these bearings. Latest news

-

ASNU 12-35 NFS TFS Roller Freewheel One Way Clutch Bearings

NewsAug.15,2025

-

Durable AK208 Pillow Block Housing | Reliable Bearing Support

NewsAug.14,2025

-

28.6x80x36.53mm W208PPB5 Heavy Duty Disc Harrow Bearing

NewsAug.13,2025

-

CKZF-B Series Flywheel Backstop Clutch: Reliable Reverse Prevention

NewsAug.12,2025

-

W210PPB6 PEER Square Bore Farm Bearings - Heavy-Duty & Durable

NewsAug.11,2025

-

UCF213-41 4-Bolt Flange Housing Square Bearing | Durable

NewsAug.10,2025