Jun . 13, 2024 11:08 Back to list

Spherical roller bearing clearance chart refers to a PDF document provided by manufacturers detailing the clearance specifications.

Understanding Spherical Roller Bearing Clearance in Manufacturing A Comprehensive Guide

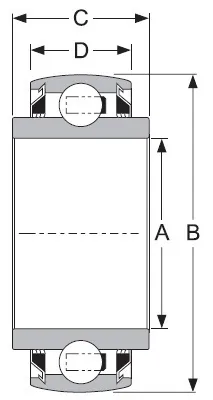

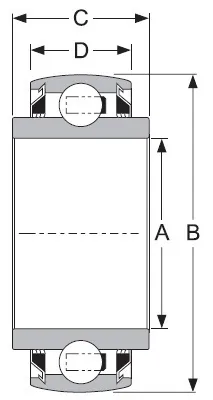

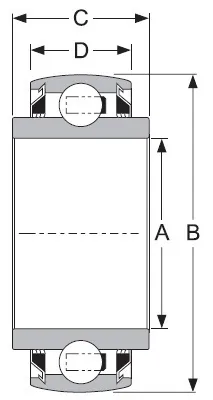

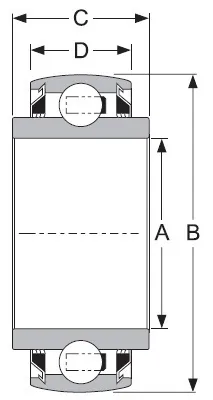

Spherical roller bearings, an integral component in various industrial applications, play a crucial role in ensuring efficient machinery operation. These bearings, characterized by their unique design, accommodate both radial and axial loads while offering high load capacity and excellent performance under harsh conditions. One critical aspect that significantly influences their functionality is the bearing clearance. This article will delve into the significance of spherical roller bearing clearance, its impact on performance, and how it is represented in manufacturers' clearance charts.

Bearing clearance, also known as pre-load, refers to the gap between the inner and outer rings of a bearing when no external forces are applied. It is essential for maintaining optimal performance, as it affects factors like heat dissipation, load distribution, and rotational accuracy. In the case of spherical roller bearings, the clearance is often classified into three categories C0 (standard), C3 (free), and C4 (large), with C0 being the smallest and C4 the largest.

Manufacturers provide detailed spherical roller bearing clearance charts in PDF format to guide engineers and technicians in selecting the appropriate clearance for specific applications. These charts typically include dimensions, tolerances, and recommended clearances for different sizes and types of bearings. They also consider factors such as operating speed, temperature, and load conditions to ensure optimal performance and longevity They also consider factors such as operating speed, temperature, and load conditions to ensure optimal performance and longevity They also consider factors such as operating speed, temperature, and load conditions to ensure optimal performance and longevity They also consider factors such as operating speed, temperature, and load conditions to ensure optimal performance and longevity

They also consider factors such as operating speed, temperature, and load conditions to ensure optimal performance and longevity They also consider factors such as operating speed, temperature, and load conditions to ensure optimal performance and longevity spherical roller bearing clearance chart pdf manufacturers.

When interpreting these charts, it's important to understand that the clearance value can significantly influence the bearing's life cycle. A tighter clearance might lead to increased heat generation due to increased friction, while a larger clearance could result in reduced load carrying capacity and increased vibration. Therefore, selecting the right clearance is a delicate balance between these factors.

Moreover, manufacturers often offer customized clearance options to cater to unique application requirements. These tailored bearings can be pre-set to a specific clearance during the manufacturing process, ensuring consistent performance across different operational scenarios.

In conclusion, spherical roller bearing clearance is a vital consideration in manufacturing processes. The comprehensive clearance charts provided by manufacturers serve as indispensable tools for engineers, assisting them in making informed decisions based on specific application needs. By understanding and correctly interpreting these charts, one can optimize bearing performance, minimize maintenance costs, and ultimately enhance the overall efficiency of industrial systems.

spherical roller bearing clearance chart pdf manufacturers.

When interpreting these charts, it's important to understand that the clearance value can significantly influence the bearing's life cycle. A tighter clearance might lead to increased heat generation due to increased friction, while a larger clearance could result in reduced load carrying capacity and increased vibration. Therefore, selecting the right clearance is a delicate balance between these factors.

Moreover, manufacturers often offer customized clearance options to cater to unique application requirements. These tailored bearings can be pre-set to a specific clearance during the manufacturing process, ensuring consistent performance across different operational scenarios.

In conclusion, spherical roller bearing clearance is a vital consideration in manufacturing processes. The comprehensive clearance charts provided by manufacturers serve as indispensable tools for engineers, assisting them in making informed decisions based on specific application needs. By understanding and correctly interpreting these charts, one can optimize bearing performance, minimize maintenance costs, and ultimately enhance the overall efficiency of industrial systems.

They also consider factors such as operating speed, temperature, and load conditions to ensure optimal performance and longevity They also consider factors such as operating speed, temperature, and load conditions to ensure optimal performance and longevity

They also consider factors such as operating speed, temperature, and load conditions to ensure optimal performance and longevity They also consider factors such as operating speed, temperature, and load conditions to ensure optimal performance and longevity spherical roller bearing clearance chart pdf manufacturers.

When interpreting these charts, it's important to understand that the clearance value can significantly influence the bearing's life cycle. A tighter clearance might lead to increased heat generation due to increased friction, while a larger clearance could result in reduced load carrying capacity and increased vibration. Therefore, selecting the right clearance is a delicate balance between these factors.

Moreover, manufacturers often offer customized clearance options to cater to unique application requirements. These tailored bearings can be pre-set to a specific clearance during the manufacturing process, ensuring consistent performance across different operational scenarios.

In conclusion, spherical roller bearing clearance is a vital consideration in manufacturing processes. The comprehensive clearance charts provided by manufacturers serve as indispensable tools for engineers, assisting them in making informed decisions based on specific application needs. By understanding and correctly interpreting these charts, one can optimize bearing performance, minimize maintenance costs, and ultimately enhance the overall efficiency of industrial systems.

spherical roller bearing clearance chart pdf manufacturers.

When interpreting these charts, it's important to understand that the clearance value can significantly influence the bearing's life cycle. A tighter clearance might lead to increased heat generation due to increased friction, while a larger clearance could result in reduced load carrying capacity and increased vibration. Therefore, selecting the right clearance is a delicate balance between these factors.

Moreover, manufacturers often offer customized clearance options to cater to unique application requirements. These tailored bearings can be pre-set to a specific clearance during the manufacturing process, ensuring consistent performance across different operational scenarios.

In conclusion, spherical roller bearing clearance is a vital consideration in manufacturing processes. The comprehensive clearance charts provided by manufacturers serve as indispensable tools for engineers, assisting them in making informed decisions based on specific application needs. By understanding and correctly interpreting these charts, one can optimize bearing performance, minimize maintenance costs, and ultimately enhance the overall efficiency of industrial systems. Latest news

-

25x52x44.4mm UEL205 Bearing with Eccentric Sleeve

NewsAug.19,2025

-

High Quality 6319 2RS Deep Groove Ball Bearing 95x200x45

NewsAug.18,2025

-

UCT205-15 Take Up Housing Pillow Block Bearing | Reliable

NewsAug.17,2025

-

CKZ-A Sprag Type Freewheels One Way Clutch - High Performance & Reliable

NewsAug.16,2025

-

ASNU 12-35 NFS TFS Roller Freewheel One Way Clutch Bearings

NewsAug.15,2025

-

Durable AK208 Pillow Block Housing | Reliable Bearing Support

NewsAug.14,2025