Jun . 24, 2024 07:02 Back to list

Spherical Bearing Design Concepts and Principles

Spherical Bearing Design A Revolution in Rotary Systems

In the realm of mechanical engineering, the design of spherical bearings represents a pivotal advancement, enhancing the efficiency and longevity of rotary systems across various industries. Spherical bearings, as their name suggests, are designed to accommodate shaft misalignments, offering unparalleled flexibility and support compared to traditional radial and axial bearing arrangements.

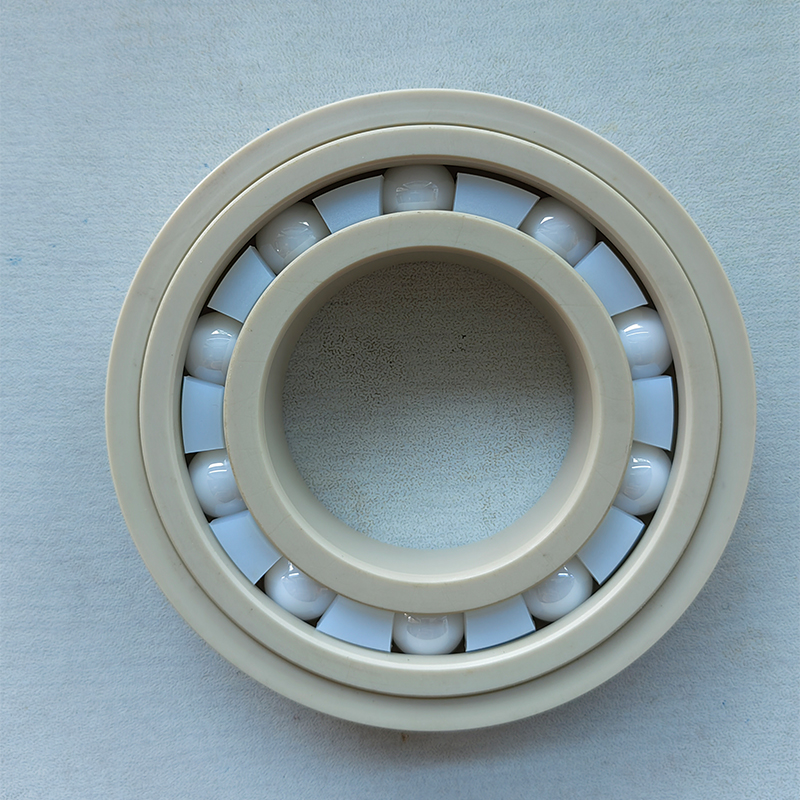

The core principle behind spherical bearing design lies in its unique structure, which includes an inner ring, an outer ring, and a spherical rolling element—typically balls or rollers. This configuration allows for rotational motion in not just a single plane but also accommodates angular movements, thereby reducing stress concentrations and increasing operational smoothness. As a result, spherical bearings are particularly well-suited for applications where precise alignment is challenging or where slight misalignments are inevitable due to operational conditions or thermal expansion.

The design process of spherical bearings is intricate, requiring meticulous calculation and material selection. Material choices play a critical role in determining the bearing's load capacity, speed compatibility, and durability. Common materials include high-carbon chrome steel for the rolling elements and either bronze or steel for the races, depending on the application's requirements. The race curvature and the tolerances between the rolling elements and races are finely tuned to ensure optimal contact stress distribution, minimizing wear and maximizing service life.

One of the significant challenges in spherical bearing design is managing the internal clearance and preload. Internal clearance refers to the gap between the rolling elements and races when the bearing is not under load Internal clearance refers to the gap between the rolling elements and races when the bearing is not under load Internal clearance refers to the gap between the rolling elements and races when the bearing is not under load Internal clearance refers to the gap between the rolling elements and races when the bearing is not under load

Internal clearance refers to the gap between the rolling elements and races when the bearing is not under load Internal clearance refers to the gap between the rolling elements and races when the bearing is not under load spherical bearing design. Proper clearance is essential for allowing lubricant flow and accommodating thermal expansion. However, excessive clearance can lead to noise and reduced accuracy. Preload, on the other hand, eliminates any potential play in the bearing, improving stiffness and precision but at the cost of increased friction and heat generation. Striking the right balance is crucial for the performance and reliability of the system.

Innovations in spherical bearing design have included the integration of seals to protect against contamination, the development of hybrid ceramic materials for rolling elements to reduce wear and improve high-temperature performance, and the use of advanced lubrication systems to enhance operational efficiency. These advancements, combined with continuous improvements in manufacturing precision, have expanded the applicability of spherical bearings into high-precision machinery, aerospace components, and even robotics.

Spherical bearing design epitomizes the synergy of science and engineering, pushing the boundaries of rotary mechanics. Its ability to handle complex loading conditions and misalignments has revolutionized the way we think about rotary support systems. As technology continues to evolve, the future of spherical bearings promises further innovations, ensuring that this essential component remains at the forefront of mechanical design excellence.

spherical bearing design. Proper clearance is essential for allowing lubricant flow and accommodating thermal expansion. However, excessive clearance can lead to noise and reduced accuracy. Preload, on the other hand, eliminates any potential play in the bearing, improving stiffness and precision but at the cost of increased friction and heat generation. Striking the right balance is crucial for the performance and reliability of the system.

Innovations in spherical bearing design have included the integration of seals to protect against contamination, the development of hybrid ceramic materials for rolling elements to reduce wear and improve high-temperature performance, and the use of advanced lubrication systems to enhance operational efficiency. These advancements, combined with continuous improvements in manufacturing precision, have expanded the applicability of spherical bearings into high-precision machinery, aerospace components, and even robotics.

Spherical bearing design epitomizes the synergy of science and engineering, pushing the boundaries of rotary mechanics. Its ability to handle complex loading conditions and misalignments has revolutionized the way we think about rotary support systems. As technology continues to evolve, the future of spherical bearings promises further innovations, ensuring that this essential component remains at the forefront of mechanical design excellence.

Internal clearance refers to the gap between the rolling elements and races when the bearing is not under load Internal clearance refers to the gap between the rolling elements and races when the bearing is not under load

Internal clearance refers to the gap between the rolling elements and races when the bearing is not under load Internal clearance refers to the gap between the rolling elements and races when the bearing is not under load spherical bearing design. Proper clearance is essential for allowing lubricant flow and accommodating thermal expansion. However, excessive clearance can lead to noise and reduced accuracy. Preload, on the other hand, eliminates any potential play in the bearing, improving stiffness and precision but at the cost of increased friction and heat generation. Striking the right balance is crucial for the performance and reliability of the system.

Innovations in spherical bearing design have included the integration of seals to protect against contamination, the development of hybrid ceramic materials for rolling elements to reduce wear and improve high-temperature performance, and the use of advanced lubrication systems to enhance operational efficiency. These advancements, combined with continuous improvements in manufacturing precision, have expanded the applicability of spherical bearings into high-precision machinery, aerospace components, and even robotics.

Spherical bearing design epitomizes the synergy of science and engineering, pushing the boundaries of rotary mechanics. Its ability to handle complex loading conditions and misalignments has revolutionized the way we think about rotary support systems. As technology continues to evolve, the future of spherical bearings promises further innovations, ensuring that this essential component remains at the forefront of mechanical design excellence.

spherical bearing design. Proper clearance is essential for allowing lubricant flow and accommodating thermal expansion. However, excessive clearance can lead to noise and reduced accuracy. Preload, on the other hand, eliminates any potential play in the bearing, improving stiffness and precision but at the cost of increased friction and heat generation. Striking the right balance is crucial for the performance and reliability of the system.

Innovations in spherical bearing design have included the integration of seals to protect against contamination, the development of hybrid ceramic materials for rolling elements to reduce wear and improve high-temperature performance, and the use of advanced lubrication systems to enhance operational efficiency. These advancements, combined with continuous improvements in manufacturing precision, have expanded the applicability of spherical bearings into high-precision machinery, aerospace components, and even robotics.

Spherical bearing design epitomizes the synergy of science and engineering, pushing the boundaries of rotary mechanics. Its ability to handle complex loading conditions and misalignments has revolutionized the way we think about rotary support systems. As technology continues to evolve, the future of spherical bearings promises further innovations, ensuring that this essential component remains at the forefront of mechanical design excellence. Latest news

-

25x52x44.4mm UEL205 Bearing with Eccentric Sleeve

NewsAug.19,2025

-

High Quality 6319 2RS Deep Groove Ball Bearing 95x200x45

NewsAug.18,2025

-

UCT205-15 Take Up Housing Pillow Block Bearing | Reliable

NewsAug.17,2025

-

CKZ-A Sprag Type Freewheels One Way Clutch - High Performance & Reliable

NewsAug.16,2025

-

ASNU 12-35 NFS TFS Roller Freewheel One Way Clutch Bearings

NewsAug.15,2025

-

Durable AK208 Pillow Block Housing | Reliable Bearing Support

NewsAug.14,2025