Apr . 24, 2024 11:12 Back to list

Rolling-element bearings design and applications

Rolling-element bearings are also called antifriction bearings, as they have lower friction and reduced lubrication requirements compared to plain bearings. Their role is to support and to guide rotating and oscillating machine elements, such as shafts, wheels or axels, and to transfer loads between the different components of an assembly.

They come in standard sizes, are easy to replace and cost-effective. By minimizing friction and enabling high rotational speeds, these bearings reduce the heat and energy consumption, leading to more efficient processes.

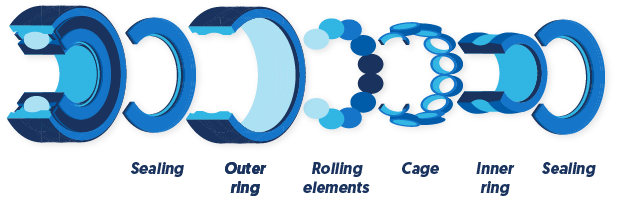

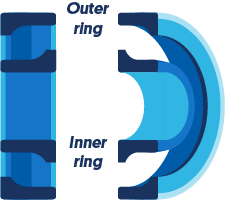

Antifriction bearings usually consist of two raceways – an inner ring and an outer ring, rolling elements which can be balls or rollers, and a cage that separates the rolling elements at specific intervals and keeps them in place inside the raceways, while enabling them to rotate freely.

The raceways are the components of a bearing that support the loads placed on the device. When a bearing is mounted in an assembly, the inner ring of the bearing fits around the shaft or axle, while the outer ring fits on the housing.

The rings are usually made of special chrome alloy steel with a high purity and hardness, and are hardened, ground and honed. Ceramic and plastic materials may also be used, especially in sectors where a lighter weight may be necessary – for example, in the automotive industry. Still, these materials cannot withstand the same temperatures or loads as steel.

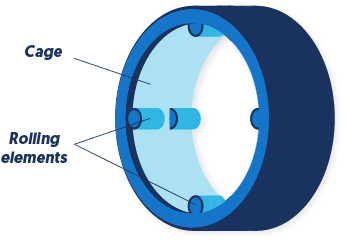

The cage holds the rolling elements in place and prevents them from falling out when the bearing is handled. Thanks to the design of the bearing, the load is never applied directly on the cage. This component can be manufactured using different methods, but the common types include pressed, formed and machined cages. As for materials, usual options include steel, plastic and brass.

Finally, the rolling elements fall into two main categories, that distinguish also the basic types of rolling bearings: ball elements, which are found in ball bearings, and rollers, which are found in roller bearings. In case of balls, the contact with the raceways is in specific points, while for rollers the contact surfaces are slightly bigger and linear.

These particularities make ball bearings more suitable for applications where higher speeds are needed, as the small contact areas provide low rolling friction. However, ball bearings have a limited load-carrying capacity, so in case of applications where heavier loads are involved, roller bearings may be preferred. Thanks to their larger contact with the raceways, roller bearings have higher friction and better load-bearing capacity, but lower speeds.

The rollers can come in the shape of cylinders, cones, spheres or needles, and are made from high purity chrome alloy steel, just like the balls. Sometimes, special materials like ceramics or plastic can also be used.

Ball bearings

Ball bearings are classified into two main groups, depending on the configuration of the rings: deep groove ball bearings and angular contact ball bearings. Both types can withstand radial and axial forces, therefore they can be further classified into radial ball bearings and thrust ball bearings.

Another classification criterion includes the number of rolling rows – single, double or four row, and the separation or lack of separation between the rings.

Considering all these criteria, we can distinguish several models of ball bearings:

single row deep groove ball bearings,

single row angular contact ball bearings,

double row angular contact ball bearings,

four-point contact ball bearings,

self-aligning ball bearings,

single direction thrust ball bearings and so on.

Ball bearings are used in a variety of applications, from simpler devices like skateboards to complex machines or engines. In the aerospace industry for example, bearings can be used in gearboxes, engines and pulleys. The materials these bearings are made of can include not only steel but also special ceramics like silicon nitride or titanium-carbide coated 440C stainless steel.

Other common applications of ball bearings include electric motors and generators, pumps and compressors, blowers, fans, gear boxes and drives, turbines, farm machinery, conveying systems, oil field machinery, robotics, industrial valves and so on.

Deep groove ball bearings

Ball bearings are the most common type of rolling-element bearing, and from these, the most used ones are deep groove ball bearings. These are radial bearings which can have a single or a double row of balls, and come in different construction types, such as Conrad type or slot-fill radial bearings.

The name of these compounds is given by the deep grooves formed on the inner and outer rings. In the Conrad design, the inner ring is initially placed into an eccentric position relative to the outer one, and the balls are inserted into the bearing through the gap that forms between the two rings.

Once they are distributed evenly in the bearing assembly, the rings become concentric, therefore the cage can also be added to the bearing. The role of the cage, as previously mentioned, is not to support loads, but to keep the balls in place during operation.

The inner ring is usually fastened to the rotating shaft, while the outer ring is mounted onto the bearing housing. When a load is applied on the bearing housing, it is transmitted from the outer race to the balls, and from the balls to the inner race. Deep groove ball bearings are suitable for applications where high loads and speeds are involved.

In the slot-fill design, more balls can be assembled between the two rings, therefore the radial load capacity of the bearing is higher than in the Conrad bearings. However, the axial load-bearing capacity of these components is not that good.

Deep groove ball bearings are available as open type bearings that allow for easy lubrication, but have the disadvantage that the balls can collect dust. An alternative construction is the bearings with metal shields and / or seals, where the contamination is moderate. Bearings with shields or seals on both sides are lubricated for life, therefore require minimum to no maintenance.

Bearings with shields or seals are also called capped bearings. Although the design may vary, the seals are fitted in general on the outer ring, and can come in the form of non-contact seals, low-friction seals or shields.

Shields are used in applications where the inner ring rotates and are fitted on the outer ring, forming a narrow gap with the inner ring. They protect from dust and dirt and are generally made of sheet steel. Seals are generally more effective than shields as they create smaller gaps with the inner rings. They can be operated at speeds similar to shields or higher, and are made of sheet steel reinforced NBR or similar materials, which are resistant to wear.

As for the cages in deep groove ball bearings, their construction can also vary, but some common designs are ribbon-type cages made of steel or brass sheets, riveted cages of brass sheet or steel, machined brass cages or snap-type cages made of polyamide 6,6.

To conclude, deep groove ball bearings are versatile devices, suitable for high and very high speeds, robust in operation and requiring little maintenance. They can accommodate radial loads and axial loads in both directions and in the single-row design, deep groove ball bearings are the most widely used type of bearing.

Angular contact ball bearings

Angular contact ball bearings also come in various designs, being available as single or double row, matched pair or four-point contact bearings. Their construction allows these elements to withstand both axial and radial forces, therefore they are suitable for applications with high loads and speeds.

Unlike deep groove ball bearings, angular ones use axially asymmetric races, the contact angle between the rings and the balls being formed when the bearing is in use. A particularity of these bearings is that one or both of the ring races – typically the outer ring - have one shoulder higher than the other.

These bearings function properly when assembled with a thrust load. The contact angle usually varies between 10 and 45 degrees, and when this angle increases, the thrust capacity also increases.

Angular contact bearings can come in different design styles, with seals or shielding. These serve not only as protection from contamination but also as retainers for lubricants. These bearings can be made from stainless steel, ceramic hybrid materials or plastic, and may be plated with chrome, cadmium or other materials. Also, they can be pre-lubricated, re-lubricated or can feature solid lubrication.

Roller bearings

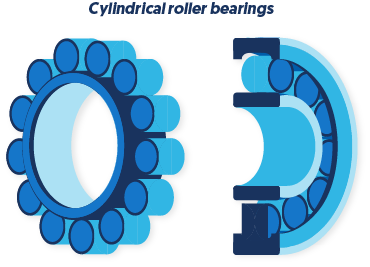

Roller bearings are classified into different types depending on the shape of the rolling elements. The main categories of roller bearings include cylindrical bearings, needle bearings, tapered bearings and spherical roller bearings.

CYLINDRICAL ROLLER BEARINGS

Cylindrical roller bearings are engineered to withstand heavy radial loads and moderate thrust loads, and they contain cylindrically-shaped rollers designed to reduce stress concentrations.

The rollers are in linear contact with the raceways, and are usually made of steel. Materials like polyamide or brass can also be used in cylindrical roller bearings for the cages.

These types of bearings have low friction and long service life, low noise and heat generation, and can be used in applications where high speeds are involved. Cylindrical roller bearings come in different styles, the designations varying depending on the manufacturer.

These bearings can be classified based on the number of roller rows. From this point of view, these machine components are divided into single row cylindrical roller bearings, double row and four row cylindrical roller bearings. In the single row models, for all designations, the inner and outer rings are separable, meaning that the inner ring with roller and the cage assembly can be mounted independently of the outer ring.

Depending on the design, the rings can come with or without ribs, so they can move axially relative to each other. There are also models available with no cage, and in this case they function with a full complement of rollers, which allows for higher loads but lower speeds.

Cylindrical roller bearings are often used in industries like petroleum production, power generation, mining, construction equipment, gears and drives, electric motors, blowers, fans, as well as pumps, machine tools and rolling mills.

SPHERICAL ROLLER BEARINGS

Spherical roller bearings are suitable for low to medium speed applications, and can withstand heavy loads. Given that they are self-aligning, they are used in applications with severe misalignment, vibration and shocks, as well as in contaminated environments.

Usually made of alloy steels, brass, polyamide or low-carbon steels, these bearings are also available in chrome-plated models.

The rotating shaft supported in the bore of the inner ring can be misaligned in respect to the outer ring, this particularity being possible thanks to the spherical internal shape of the outer ring and to the shape of the rollers, which aren’t actually spherical but cylindrical.

Robust and designed for heavy radial loads, these bearings have a long service life and low friction. They are typically used in applications like gearboxes, pumps, mechanical fans and blowers, wind turbines, marine propulsion and offshore drilling, mining and construction equipment and so on.

In what concerns the design of these bearings, they have an inner ring with two raceways inclined at an angle to the bearing axis, a cage and an outer ring with a common spherical raceway. The spherical rollers are most commonly distributed in two rows, this design allowing the bearings to withstand very heavy radial and axial loads.

Spherical roller bearings can run at lower temperatures compared to other bearings, and they come in standardized sizes, the international norm for these devices being ISO 15:1998. Common series include 21300, 22200, 22300, 23000, 23100, 23200 and so on.

Spherical bearings are available with sealings and are delivered lubricated. This design reduces grease, protects against dirt, dust and other contaminants and simplifies maintenance, extending the service life of the bearings.

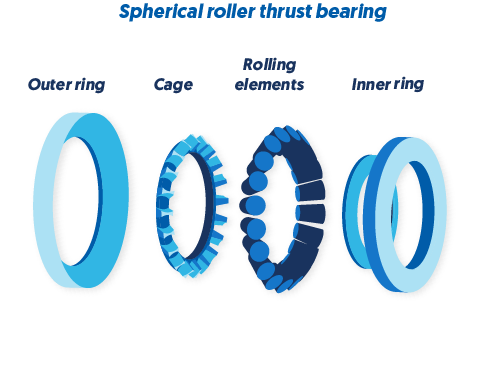

SPHERICAL ROLLER THRUST BEARINGS

Similarly to spherical roller bearings, spherical roller thrust bearings are designed to permit angular misalignment and rotation with low friction, being suitable for radial loads and heavy axial loads in one direction.

These bearings are made of a shaft washer which is the equivalent of the inner ring, a housing washer which is the equivalent of the outer ring, asymmetrical rollers and a cage. The external dimensions are standardized by the norm ISP 104:2002, the most common series including 292, 293 and 294.

Just like spherical roller bearings, the thrust bearings can be made of different materials, such as chrome steel, brass, sheet steel and so on. These bearings are used in applications with moderate speeds, some common applications being water turbines, gearboxes, cranes, marine propulsion and offshore drilling, extruders for injection molding and pulp and paper processing equipment.

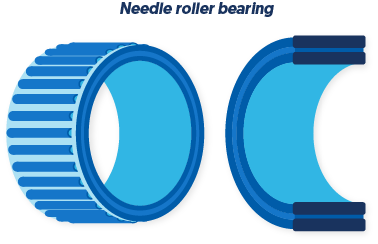

NEEDLE ROLLER BEARINGS

In needle roller bearings, the rolling elements are shaped like thin cylinders that resemble needles. This particular design, in which the length of the rollers is a few times higher than the diameter, not only makes them stand out from other types of bearings but also gives needle roller bearings a significant load-bearing capacity.

Used for reducing the friction of a rotating surface within an assembly, needle roller bearings have a small cross-sectional height, are thinner than other bearings and require less clearance between the axle and the surrounding elements.

With greater rigidity and lower inertia forces acting on them, these bearings are ideal for applications with oscillating motion and perform well under severe conditions. They also facilitate size and weight reductions in machine designs and can serve as replacements for sliding bearings.

The smallest and lightest of the roller bearing family, needle roller bearings are widely used in the automotive industry, in components such as compressors, transmissions, rocker arm pivots or pumps. These bearings are also commonly used in agricultural applications and construction equipment, in portable power tools and domestic appliances.

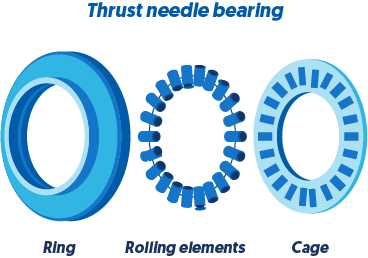

In what concerns the different types of needle roller bearings, these are classified into radial and thrust bearings, depending on the direction of the load. Thrust bearings include thrust needle bearings, while radial ones include drawn cup bearings, solid needle roller bearings, radial caged needle rollers, track rollers, heavy-duty machined needle roller bearings, and combined radial and thrust bearings.

Solid needle roller bearings feature an outer ring with strong integrated ribs which keep the rollers in place and ensure high operating speeds. The ring is precisely ground after being heat treated, therefore can withstand high shock loads. The cage is also treated to increase the wear resistance and rigidity, and if needed, crowning can be applied to reduce the loads on the roller edges. The outer ring features a lubrication hole or groove that makes it easy to replace the lubricant, extending the life of the bearing.

Radial caged needle rollers or needle roller and cage assemblies have no inner or outer ring, their design consisting only of a complement of needle rollers that are held in place by a cage. This cage provides inward and outward retention for the rolling elements and ensures maximum strength as well as accurate guidance for the rollers even at high speeds.

Radial caged needle rollers have a low cross section, a high load-carrying capacity, and their design creates favorable lubricating conditions. The cage can be made of steel or of glass-reinforced polymer material, and if needed, crowning can be applied on both ends of the rollers to prevent stress concentrations at the edges. Common applications include planetary gears, idler gears and connecting rods.

Drawn cup needle bearings are available as caged and full complement models, both of them featuring an outer ring which is made of alloy steel sheet. This shell is accurately drawn in the form of a cup and surface-hardened through pressing, so it ensures a tight line contact with the rollers. This construction gives the bearing a high load-carrying capacity, and because no additional machining is needed for the shell, it also makes it an economical solution.

Drawn cup needle bearings have a low height which makes them suitable for compact and lightweight machine designs. The bent parts of the outer ring keep the rollers in place and prevent dust and dirt from entering the bearing, while also ensuring good bearing lubrication. Another advantage of this design is that if the shaft has proper hardness and dimensions, the bearing doesn’t require an internal ring, therefore more space can be saved in the radial direction.

The full complement drawn cup needle bearings can carry loads equal to or higher than ball and roller bearings of comparable outer diameters, and are suitable for static, slow rotating and oscillating conditions. They can be used in housings of low hardness, and have maximum load capacity when the rollers are held in place by grease before assembly, as the rollers have the longest possible length.

In what concerns the drawn cup caged bearings, they can also be used in housings of low hardness but have a lower load capacity than full complement ones. Still, they are excellent for high speed and shaft misalignment applications. The surface of the cage is hardened therefore the wear resistance and the rigidity are increased, while the frictional torque is reduced.

As the cage creates some extra space for storing lubricant, these needle bearings operate smoothly and have a long grease life. Common applications for drawn cup needle roller bearings include gear pumps, general gearbox shaft supports, pilot bearings and pulley supports.

Track rollers have thick-walled outer rings that run directly on a track and allow for high loads, while minimizing distortion, shocks and bending stresses. These are commonly used in machine ways, mast rollers and cam followers, and are also referred to as cam followers.

The outer ring is usually made of high-carbon chromium steel, which is resistant to deformation, and features holes for lubrication. If needed, crowning can be applied on the rollers to prevent excessive loads at the edges. Also, thrust washers can be integrated in the design to enhance resistance.

These needle bearings come in two main designs, for different mounting arrangements: yoke type, which is suitable for straddle or clevis mounting, and integral stud type, suitable for cantilever mounting. The stud type bearings are available with or without lip contact seals and shields, while the yoke type bearings are available with either radial needle roller and cage assemblies, or with full complement cylindrical or needle rollers.

Thrust needle bearings consist of a complement of needle rollers held in place by a cage. They have small cross sections and the cage is made of two steel sheets precisely pressed, which guide the rollers accurately and increase the rigidity and wear resistance of the device. These bearings transmit thrust loads between two rotating objects while reducing friction.

Combined radial and thrust bearings consist of a thrust ball or roller bearing and a radial needle roller bearing. Some of them are similar to drawn cup bearings, but with an added thrust bearing. These devices are designed to withstand high speeds and high axial loads in limited spaces, and can be used instead of plain thrust washers, when superior load capacity and frictional characteristics are needed. A common application is automatic transmissions.

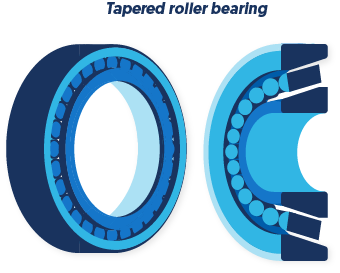

TAPERED ROLLER BEARINGS

Tapered roller bearings consist of an inner ring or cone, an outer ring or cup, a cage and rollers which are profiled to distribute the loads evenly. These bearings use conical rollers guided by a rib on the cone, and are capable of withstanding high radial and axial loads in one direction.

The inner and outer ring raceways are segments of cones, and the rollers are tapered, this design enabling a coaxial motion of the cones and no sliding motion between the raceways and the outer diameters of the rollers. Thanks to their shape, tapered roller bearings can support higher loads than spherical ball bearings.

The flange on the inner ring which keeps the rollers stable prevents them from popping out. The inner ring, rollers and cage form a non-separable cone assembly, while the outer ring is shaped like a cup and separable. The cone assembly and cup can be mounted independently, and proper internal clearance can be obtained by adjusting the axial distance between these components for two opposed bearings.

Depending on the contact angle, tapered roller bearings can be classified into three types: normal angle, medium angle and steep angle. Also, based on the number of rows, they can be classified into:

Single row tapered roller bearings, which have one cup and one cone assembly. In this category are included the series TS and TSF (single row with flanged outer ring).

Double row tapered roller bearings which use one double cup (outer ring) and two single cone roller assemblies (inner rings). The TDO series is included here.

Double row tapered roller bearings which use a double-cone assembly (double inner ring) and two single cups (outer rings). The TDI and TDIT series are included here.

Four rows tapered roller bearings which use a combination of double and single components, such as two TDI cones, two TS cups and one TDO cup with cup or cone spacers. The TQO series is included here.

Single-row bearings have a higher thrust load capacity, while double-row bearings have a greater radial load capacity and can handle thrust loads in both directions. The standard cage is the pin-type design, which can withstand high loads and speeds. Pressed steel cages are generally used. In many applications, these bearings are used in back-to-back pairs to support axial forces in either direction.

Additionally, tapered roller bearings are available in metric series:

Metric single row tapered roller bearings, which are in accordance with the standard ISO 355:2007. These are suitable for gear boxes, pumps and conveyors used in applications for the power industry, oil and gas, wind energy, food and beverage or pulp and paper industry. Also, they can be used in drive trains, gear drives and axle centers in the construction, automotive and mining industries.

Metric double row tapered roller bearings, which consist of two single-row bearings with individually matched spacers. These are used in applications that require high load capacities and where the shaft must be located axially in both directions with a specific clearance or preload. The outer ring spacer features lubrication holes. These bearings are suitable for applications like gear drives and transmissions, coal conveyors or cranes.

Common applications for tapered roller bearings include car and vehicle wheel bearings, agriculture, construction and mining equipment, gear boxes, engine motors and reducers, wind turbines, axle systems and propeller shafts.

4. Lubrication and maintenance of bearings

Proper installation and adjustment plays a vital role in the performance and life of bearings, and so does the lubricant. In most cases, the failure of bearings is not caused by improper installation or manufacturing defects, but by a lack of lubricant, an incorrectly chosen or a contaminated lubricant.

The lubricant, be it oil or grease, is spread between the moving parts of a bearing assembly and separates them, reducing friction and preventing wear. Depending on the operating conditions and on the chosen lubricant, a protective film will form on the bearing elements, the role of this film being also to dissipate the frictional heat, preventing the deterioration of the bearing and protecting against moisture, corrosion and contaminants.

A correctly chosen lubricant has the proper additives and viscosity to accomplish all the mentioned goals. The most common lubricants are oil and grease, the use of one or another being determined by the speed of the application and by the amount of load placed on the bearings.

In case of oils, the most important characteristic is the viscosity, the proper product being determined by the temperature and speed of the application. If an oil with insufficient viscosity is used, then the two rotating surfaces will come in contact and this will not only lead to wear but will also generate contact heat, and will cause the quick degradation of the bearing elements.

The most common oils for bearings are petroleum based and synthetic oils such as silicone, fluorinated compounds, diesters or PAO’s. Oils are usually chosen for bearings with higher speed capabilities and higher operating temperature, as they can carry the heat away from the bearings. In some cases, such as miniature bearings for example, oil-based lubricants only need to be applied once for the life of the bearing. In assemblies that use larger bearings, relubrication may be necessary as part of the regular machine maintenance cycle.

For grease-based lubricants, the most important characteristics are the temperature range, the penetration level, the stiffness and the viscosity of the base oil. Greases consist of an oil base in which a thickener is added, the most common thickeners being organic and inorganic compounds, as well as metal soaps like sodium, aluminum, calcium or lithium. Additives with antioxidant, anticorrosion and anti-wear characteristics can also be incorporated to increase the performance of the lubricant.

Alternatively, a solid non-fluid film can be applied like a coating on the bearing elements to reduce friction and prevent wear. These films are used in particular situations when oil or grease cannot survive, and they include options like graphite, silver, PTFE or gold films. For example, in an application with extreme temperatures or radiation, an oil- or grease-based lubricant may not offer proper protection, therefore a more durable one like a solid film may need to be used.

In most cases, grease is a good choice for lubricating bearings. More cost-efficient than oil, grease is easily retained in the bearing assembly and is easy to apply. However, it is not suitable for applications where heat removal via circulating oil is needed, nor in gearboxes where lubricating oil is required.

Also, if the operating conditions require the relubrication of bearings with grease at intervals that are too short, and this becomes too time consuming and expensive, or if the removal or purging of grease becomes too expensive and difficult to handle, it is better to choose a lubricating oil.

Lubrication levels and relubrication of bearings

After a lubricant is selected, an important aspect is applying the correct amount on the bearing. If too much lubricant is used, this can lead to excess heat generation and bearing damage. The speed of the application, the loads and the noise level can all be influenced by the amount of lubricant used.

Depending on the chosen type of bearing and lubricant and on the application, manufacturers may recommend different levels of lubrication, which are given in percentages. The lubricant goes in the free space inside a bearing and in the housing. This space is important as it allows heat to radiate away from the contact areas of the bearing, so if too much grease is added, this can lead to overheating and premature bearing failure.

For this reason, the common recommendation is to fill in 20-40% of the free internal space of a bearing, a smaller percentage being usually specified for high speed, low torque applications, and higher percentage for low speed, high load applications. For the housing, filling in even 70%-100% of the free space may be acceptable if the application involves a low speed and the risk of contamination is high.

Keep in mind that the initial fill level is also influenced by the chosen relubrication method. The common methods for re-lubricating a bearing are manual relubrication, automatic and continuous relubrication.

Manual relubrication is convenient and enables uninterrupted operation.

Automatic relubrication avoids over- and under-greasing, and is commonly used in assemblies where multiple points have to be lubricated, or where access to positions is difficult. Also, it is the preferred choice where equipment is operated remotely and there’s no maintenance staff.

Continuous lubrication is used for applications where the relubrication intervals are too short, because of the adverse effects of contamination. In this case, the initial fill of the housing will be 70%-100%, depending on the operating conditions.

Bearing maintenance tips

Handling and maintaining your bearings properly extends their service life and optimizes performance. Use this basic checklist to reduce maintenance time, labor and costs.

Bearing handling: Handle the bearings carefully to avoid scratching the surfaces. Always handle them with clean, dry hands, or use clean canvas gloves. Do not handle bearings with greasy or moist hands, as this can quickly lead to contamination.

Bearing storage: Keep bearings wrapped in oil-proof paper, in a cool and clean environment with low humidity, free of dust, vibrations and shocks. After you handle a bearing, place it on a clean and dry surface, to avoid contamination. Do not remove the bearing from its original package until you need to mount it, and store it flat, not standing.

Cleaning a bearing: Always use uncontaminated solvents or flushing oils, and avoid using cotton waste or dirty rags to wipe a bearing. Use separate containers for cleaning and for final rinsing a used bearing.

Bearing mounting: Use the correct technique and tools to mount a bearing. Around 16% of bearing failures are attributed to poor fitting, so make sure you avoid an excessively loose or excessively tight fit. Before mounting, check that all parts are clean and undamaged, and that the lubricant is correctly chosen. Do not wash the bearing before mounting it if it comes directly from a package.

Do not hammer or apply direct force on the bearing or its outer ring, as this can cause damage and misalignment of the elements. For small- and medium-sized bearings, cold mounting or mechanical mounting is generally recommended. Heat mounting is usually more appropriate for relatively large bearings, while for very large bearings, hydraulic mounting may be recommended.

Use proper tools: Specialized tools are available for mounting and dismounting bearings – bearing pullers, fitting tool kits, oil injector tools, induction heaters and hydraulic nuts. All these are customized to ensure proper fitting and a smooth mounting, to minimize the risk of bearing damage.

Inspect the bearings: To prevent bearing failure, it is necessary to inspect them both during and after operation. For inspections in operation, check the temperature, noise and vibration and examine the lubricant to determine whether it needs to be replaced or replenished. After operation, examine the bearing and each of its components to determine whether there are changes. The common causes of bearing failures and their solutions are discussed in the final chapter of this guide.

Latest news

-

Spherical Bearing Installation

NewsJun.11,2025

-

Sphere Bearing Applications About Key Uses

NewsJun.11,2025

-

Long-Lasting Bearing Options

NewsJun.11,2025

-

Deep Groove Ball Bearing Basics

NewsJun.11,2025

-

Comprehensive Guide to Zirconia Bearing Testing

NewsJun.11,2025

-

Ceramic Bearing Selection Guide

NewsJun.11,2025