Jun . 13, 2024 11:08 Back to list

Manufacturer of shop vac motor bearings supplier

Understanding Shop Vac Motor Bearings The Heart of the Machine

In the realm of industrial equipment and machinery, a shop vac is an indispensable tool for cleaning up debris and dust. At the heart of this powerful vacuum lies the motor, and within the motor, the bearings play a critical role. They are the unsung heroes that enable smooth operation and longevity. This article delves into the significance of shop vac motor bearings and the manufacturers who specialize in their production.

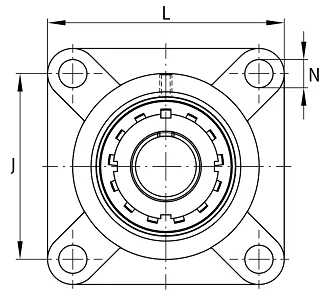

Shop vac motors, often subjected to heavy usage and constant stress, require robust and durable bearings to withstand the load and friction. These bearings, usually ball or roller types, facilitate the rotation of the motor shaft, minimizing wear and tear while ensuring efficient energy transfer. They are designed to handle both radial and axial loads, enabling the motor to function seamlessly even under demanding conditions.

Manufacturers of shop vac motor bearings understand the importance of precision engineering in this context. They employ advanced materials, such as high-strength steel, to ensure durability and resistance to heat and corrosion. The bearings are meticulously crafted with precise tolerances to reduce noise and vibration, enhancing the overall performance of the shop vac.

Leading manufacturers in this domain, such as NSK, SKF, and Timken, among others, have a reputation for producing top-quality motor bearings. They invest heavily in research and development to innovate and improve bearing designs, incorporating features like labyrinth seals to protect against dust ingress and lubrication systems that ensure optimal performance over time They invest heavily in research and development to innovate and improve bearing designs, incorporating features like labyrinth seals to protect against dust ingress and lubrication systems that ensure optimal performance over time They invest heavily in research and development to innovate and improve bearing designs, incorporating features like labyrinth seals to protect against dust ingress and lubrication systems that ensure optimal performance over time They invest heavily in research and development to innovate and improve bearing designs, incorporating features like labyrinth seals to protect against dust ingress and lubrication systems that ensure optimal performance over time

They invest heavily in research and development to innovate and improve bearing designs, incorporating features like labyrinth seals to protect against dust ingress and lubrication systems that ensure optimal performance over time They invest heavily in research and development to innovate and improve bearing designs, incorporating features like labyrinth seals to protect against dust ingress and lubrication systems that ensure optimal performance over time shop vac motor bearings manufacturer.

Moreover, these manufacturers often provide custom solutions tailored to specific shop vac requirements. They consider factors like motor size, power output, and expected usage patterns to create bearings that can handle the unique demands of each application. This personalized approach ensures that the bearings not only meet but exceed the performance expectations of users.

The reliability of shop vac motor bearings is crucial for uninterrupted operations and the overall lifespan of the equipment. A failure in these bearings can lead to motor overheating, decreased suction power, or even complete motor breakdown. Therefore, choosing the right manufacturer becomes vital. Users should consider factors such as the manufacturer's reputation, product quality, warranty, and after-sales service when making a decision.

In conclusion, shop vac motor bearings are the backbone of the machine, silently working to keep it functioning at its best. The manufacturers behind these bearings are dedicated to providing products that withstand the rigors of heavy usage and harsh environments. Their commitment to innovation, precision, and customer satisfaction ensures that shop vacs continue to be dependable workhorses in countless workshops and industries worldwide.

shop vac motor bearings manufacturer.

Moreover, these manufacturers often provide custom solutions tailored to specific shop vac requirements. They consider factors like motor size, power output, and expected usage patterns to create bearings that can handle the unique demands of each application. This personalized approach ensures that the bearings not only meet but exceed the performance expectations of users.

The reliability of shop vac motor bearings is crucial for uninterrupted operations and the overall lifespan of the equipment. A failure in these bearings can lead to motor overheating, decreased suction power, or even complete motor breakdown. Therefore, choosing the right manufacturer becomes vital. Users should consider factors such as the manufacturer's reputation, product quality, warranty, and after-sales service when making a decision.

In conclusion, shop vac motor bearings are the backbone of the machine, silently working to keep it functioning at its best. The manufacturers behind these bearings are dedicated to providing products that withstand the rigors of heavy usage and harsh environments. Their commitment to innovation, precision, and customer satisfaction ensures that shop vacs continue to be dependable workhorses in countless workshops and industries worldwide.

They invest heavily in research and development to innovate and improve bearing designs, incorporating features like labyrinth seals to protect against dust ingress and lubrication systems that ensure optimal performance over time They invest heavily in research and development to innovate and improve bearing designs, incorporating features like labyrinth seals to protect against dust ingress and lubrication systems that ensure optimal performance over time

They invest heavily in research and development to innovate and improve bearing designs, incorporating features like labyrinth seals to protect against dust ingress and lubrication systems that ensure optimal performance over time They invest heavily in research and development to innovate and improve bearing designs, incorporating features like labyrinth seals to protect against dust ingress and lubrication systems that ensure optimal performance over time shop vac motor bearings manufacturer.

Moreover, these manufacturers often provide custom solutions tailored to specific shop vac requirements. They consider factors like motor size, power output, and expected usage patterns to create bearings that can handle the unique demands of each application. This personalized approach ensures that the bearings not only meet but exceed the performance expectations of users.

The reliability of shop vac motor bearings is crucial for uninterrupted operations and the overall lifespan of the equipment. A failure in these bearings can lead to motor overheating, decreased suction power, or even complete motor breakdown. Therefore, choosing the right manufacturer becomes vital. Users should consider factors such as the manufacturer's reputation, product quality, warranty, and after-sales service when making a decision.

In conclusion, shop vac motor bearings are the backbone of the machine, silently working to keep it functioning at its best. The manufacturers behind these bearings are dedicated to providing products that withstand the rigors of heavy usage and harsh environments. Their commitment to innovation, precision, and customer satisfaction ensures that shop vacs continue to be dependable workhorses in countless workshops and industries worldwide.

shop vac motor bearings manufacturer.

Moreover, these manufacturers often provide custom solutions tailored to specific shop vac requirements. They consider factors like motor size, power output, and expected usage patterns to create bearings that can handle the unique demands of each application. This personalized approach ensures that the bearings not only meet but exceed the performance expectations of users.

The reliability of shop vac motor bearings is crucial for uninterrupted operations and the overall lifespan of the equipment. A failure in these bearings can lead to motor overheating, decreased suction power, or even complete motor breakdown. Therefore, choosing the right manufacturer becomes vital. Users should consider factors such as the manufacturer's reputation, product quality, warranty, and after-sales service when making a decision.

In conclusion, shop vac motor bearings are the backbone of the machine, silently working to keep it functioning at its best. The manufacturers behind these bearings are dedicated to providing products that withstand the rigors of heavy usage and harsh environments. Their commitment to innovation, precision, and customer satisfaction ensures that shop vacs continue to be dependable workhorses in countless workshops and industries worldwide. Latest news

-

Top Spherical Roller Bearing Material Exporter - High-Performance Alloys

NewsAug.27,2025

-

Durable PLC 110-190 Spherical Roller Bearing for Mixer Reducer

NewsAug.26,2025

-

CSK-2RS Sprag Clutch One Way Bearing: Sealed, High Torque, Durable

NewsAug.25,2025

-

CKZ-D Series One Way Overrunning Clutch: Reliable Power Control

NewsAug.24,2025

-

203KRR3 Round Bore Series Bearings | Cylindrical Outer Ring, Precision

NewsAug.23,2025

-

Top Spherical Roller Bearing Material Exporter - High Performance

NewsAug.22,2025