Jun . 16, 2024 19:28 Back to list

Large spherical bearing manufacturers.

Exploring the World of Large Spherical Bearings A Dive into Manufacturing Excellence

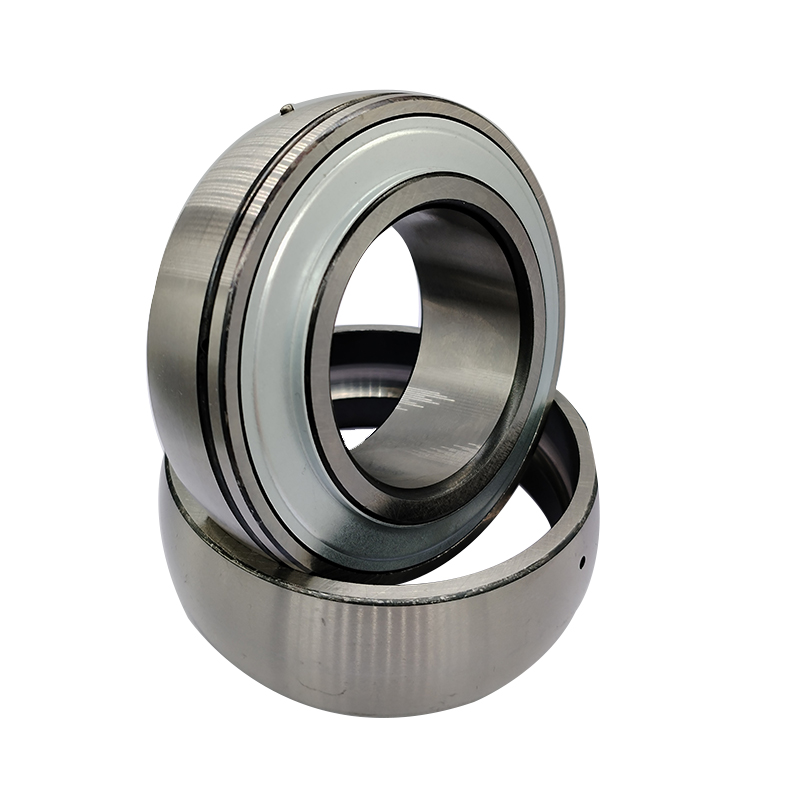

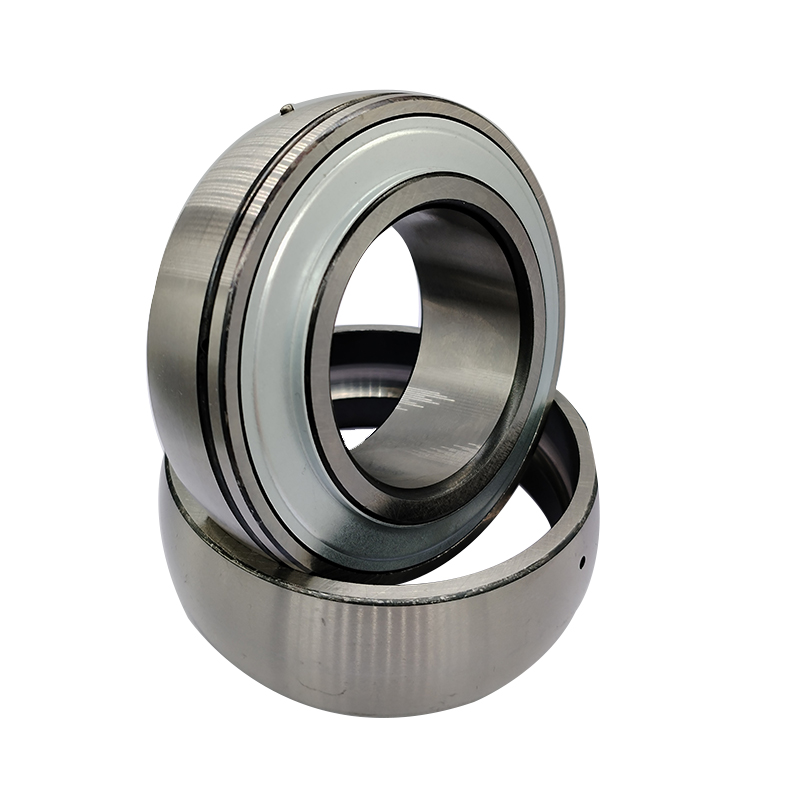

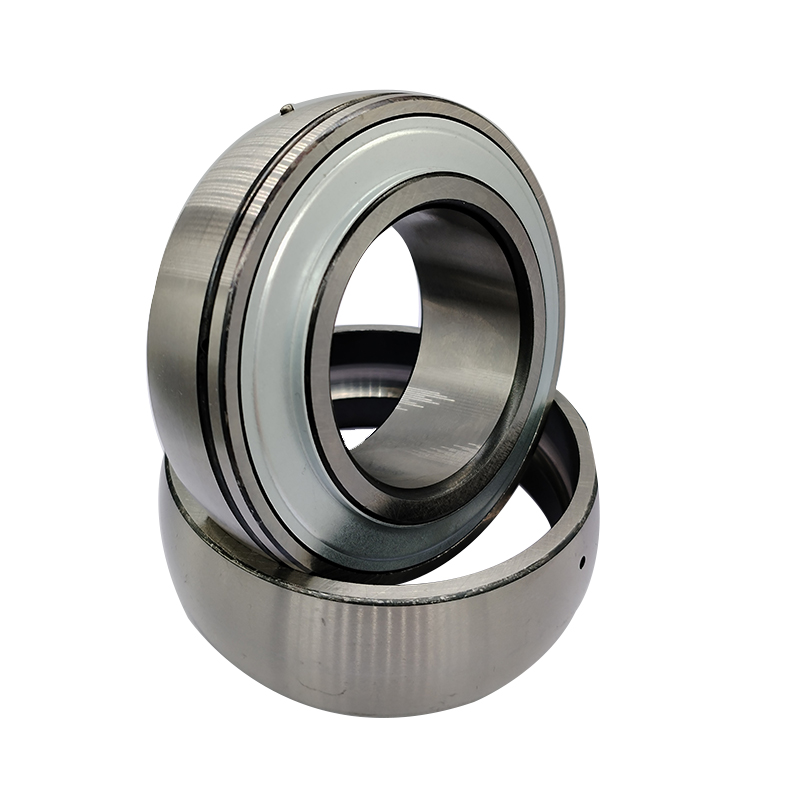

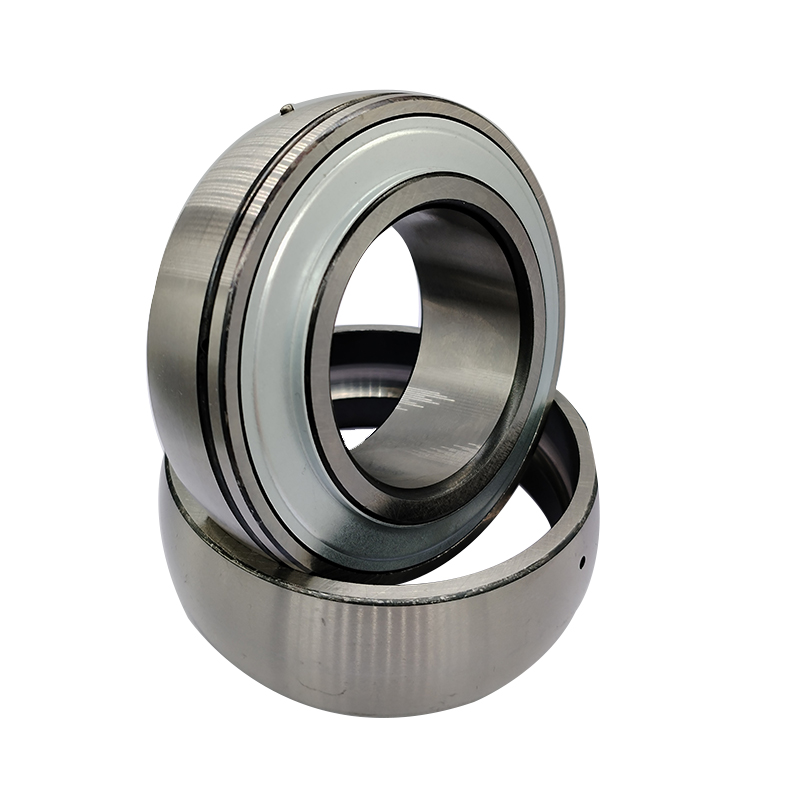

In the intricate world of machinery and industrial equipment, large spherical bearings stand as vital components that enable smooth and precise motion. These specialized bearings are designed to handle heavy loads and high stresses, making them indispensable in various sectors ranging from aerospace to construction. The manufacturing process behind these robust elements is a testament to engineering prowess and precision craftsmanship. Let's delve into the realm of large spherical bearing manufacturers and understand their commitment to excellence.

Manufacturers specializing in large spherical bearings are few but distinguished. These companies have honed their craft over decades, integrating cutting-edge technology with traditional metallurgical wisdom. They recognize the critical role these bearings play in supporting structural integrity and operational efficiency in demanding environments. As such, they spare no effort in ensuring each bearing meets stringent standards for durability, reliability, and performance.

The production journey begins with selecting high-quality raw materials, primarily high-carbon steel or alloy steel, which forms the backbone of the bearing's structure. Advanced techniques such as vacuum degassing are employed to remove impurities, resulting in steel of exceptional purity. This meticulous approach ensures the final product can withstand the rigors of heavy loads without fatigue or failure.

Once the material is prepared, it enters the machining phase where precision is paramount

Once the material is prepared, it enters the machining phase where precision is paramount Once the material is prepared, it enters the machining phase where precision is paramount

Once the material is prepared, it enters the machining phase where precision is paramount

Once the material is prepared, it enters the machining phase where precision is paramount

Once the material is prepared, it enters the machining phase where precision is paramount large spherical bearing manufacturers. Sophisticated CNC (Computer Numerical Control) machines carve out the initial shape, followed by finer processes that create the spherical geometry. Here, the art of grinding plays a crucial role, as it ensures the surface finish is flawless, reducing friction and wear.

Quality control is an ever-present companion throughout manufacturing, with rigorous testing at every stage. Non-destructive testing methods like ultrasonic and magnetic particle inspections are commonplace, guaranteeing that any imperfections are identified and rectified before the bearing leaves the factory.

Moreover, large spherical bearing manufacturers often provide custom solutions tailored to specific applications. This bespoke service involves close collaboration with clients to understand their unique requirements, thereby engineering bearings that align perfectly with the operational conditions and design specifications.

In conclusion, the manufacturing of large spherical bearings is a blend of science, technology, and art. It demands a deep understanding of materials science, precise engineering practices, and unwavering commitment to quality. The manufacturers in this niche stand out for their ability to consistently produce bearings that push the boundaries of performance and reliability. As we look towards the future, their innovation and expertise promise to keep propelling industries forward, one revolution at a time.

large spherical bearing manufacturers. Sophisticated CNC (Computer Numerical Control) machines carve out the initial shape, followed by finer processes that create the spherical geometry. Here, the art of grinding plays a crucial role, as it ensures the surface finish is flawless, reducing friction and wear.

Quality control is an ever-present companion throughout manufacturing, with rigorous testing at every stage. Non-destructive testing methods like ultrasonic and magnetic particle inspections are commonplace, guaranteeing that any imperfections are identified and rectified before the bearing leaves the factory.

Moreover, large spherical bearing manufacturers often provide custom solutions tailored to specific applications. This bespoke service involves close collaboration with clients to understand their unique requirements, thereby engineering bearings that align perfectly with the operational conditions and design specifications.

In conclusion, the manufacturing of large spherical bearings is a blend of science, technology, and art. It demands a deep understanding of materials science, precise engineering practices, and unwavering commitment to quality. The manufacturers in this niche stand out for their ability to consistently produce bearings that push the boundaries of performance and reliability. As we look towards the future, their innovation and expertise promise to keep propelling industries forward, one revolution at a time.

Once the material is prepared, it enters the machining phase where precision is paramount

Once the material is prepared, it enters the machining phase where precision is paramount

Once the material is prepared, it enters the machining phase where precision is paramount

Once the material is prepared, it enters the machining phase where precision is paramount large spherical bearing manufacturers. Sophisticated CNC (Computer Numerical Control) machines carve out the initial shape, followed by finer processes that create the spherical geometry. Here, the art of grinding plays a crucial role, as it ensures the surface finish is flawless, reducing friction and wear.

Quality control is an ever-present companion throughout manufacturing, with rigorous testing at every stage. Non-destructive testing methods like ultrasonic and magnetic particle inspections are commonplace, guaranteeing that any imperfections are identified and rectified before the bearing leaves the factory.

Moreover, large spherical bearing manufacturers often provide custom solutions tailored to specific applications. This bespoke service involves close collaboration with clients to understand their unique requirements, thereby engineering bearings that align perfectly with the operational conditions and design specifications.

In conclusion, the manufacturing of large spherical bearings is a blend of science, technology, and art. It demands a deep understanding of materials science, precise engineering practices, and unwavering commitment to quality. The manufacturers in this niche stand out for their ability to consistently produce bearings that push the boundaries of performance and reliability. As we look towards the future, their innovation and expertise promise to keep propelling industries forward, one revolution at a time.

large spherical bearing manufacturers. Sophisticated CNC (Computer Numerical Control) machines carve out the initial shape, followed by finer processes that create the spherical geometry. Here, the art of grinding plays a crucial role, as it ensures the surface finish is flawless, reducing friction and wear.

Quality control is an ever-present companion throughout manufacturing, with rigorous testing at every stage. Non-destructive testing methods like ultrasonic and magnetic particle inspections are commonplace, guaranteeing that any imperfections are identified and rectified before the bearing leaves the factory.

Moreover, large spherical bearing manufacturers often provide custom solutions tailored to specific applications. This bespoke service involves close collaboration with clients to understand their unique requirements, thereby engineering bearings that align perfectly with the operational conditions and design specifications.

In conclusion, the manufacturing of large spherical bearings is a blend of science, technology, and art. It demands a deep understanding of materials science, precise engineering practices, and unwavering commitment to quality. The manufacturers in this niche stand out for their ability to consistently produce bearings that push the boundaries of performance and reliability. As we look towards the future, their innovation and expertise promise to keep propelling industries forward, one revolution at a time. Latest news

-

High Quality 6319 2RS Deep Groove Ball Bearing 95x200x45

NewsAug.18,2025

-

UCT205-15 Take Up Housing Pillow Block Bearing | Reliable

NewsAug.17,2025

-

CKZ-A Sprag Type Freewheels One Way Clutch - High Performance & Reliable

NewsAug.16,2025

-

ASNU 12-35 NFS TFS Roller Freewheel One Way Clutch Bearings

NewsAug.15,2025

-

Durable AK208 Pillow Block Housing | Reliable Bearing Support

NewsAug.14,2025

-

28.6x80x36.53mm W208PPB5 Heavy Duty Disc Harrow Bearing

NewsAug.13,2025