Apr . 22, 2024 15:18 Back to list

heavy duty spherical bearing What is a Bearing?

The formal technical definition of a bearing is a machine element that:

- Constrains relative motion between two parts to that specified in an overall design.

- Reduces friction between these moving parts.

A simpler definition can be found in the name “bearing” itself: a supporting structure designed to “bear” stress or load within a given design.

While the prototypical use case for bearings is an axle rotating in a shaft, they can be engineered to facilitate many different desired ranges of motion. Linear bearings, for instance (see below), allow for linear rather than rotational motion, with the bearing element moving along a rail or rod.

The actual design of the part performing this function can vary widely. Bearings can be made of materials ranging from wood to brass to advanced polymers. Some bearing designs rely on frequent lubrication, while others operate in environments where they can almost never be lubricated (like space). Some bearings are designed to resist corrosion while remaining submerged for long periods of time, while others need to operate under the high-heat conditions of steel manufacturing plants.

Today, bearings are highly-engineered components built for highly specific applications, environmental hazards, maintenance requirements, and price-points.

Bearing Basics

In the prototypical case of a rotational bearing, the “journal” is the part of the shaft which contacts the bearing surface. In the simplest possible case, a bearing is not a discrete device: the journal simply slides over the bearing surface, enduring any friction, heat, and wear generated. While usable in less demanding contexts, bearing designs that do little to reduce friction will create unacceptable magnitudes of heat and wear when used at the speeds and conditions required by demanding modern applications in fields like industrial manufacturing, aerospace, and automotive.

A huge imperative in bearing design, therefore, is reducing friction to improve the bearing’s performance characteristics and lifespan.

Several additional features can be added to reduce friction, first lubrication. Traditionally, this was done by the initial and periodic injection of grease or oil. Today, some designs embed advanced lubricants into the bearing material themselves (see Self-Lubricating Bearings, below) reducing manual lubrication needs. Other designs utilize low-friction materials that don’t require lubrication at all under the right operating conditions.

A second option is the addition of a rolling design element to reduce friction while preserving desired load-bearing characteristics. Bearing designs can be usefully divided into two high-level categories based on this addition.

Sleeve / Journal Bearing vs Roller Bearing

- Ball/Roller Bearing: In these designs, a rolling element is placed between two sleeves: an inner sleeve, contacting the journal, and an outer-sleeve contacting the bore. A “ball” is the most common form of rolling element, but these can also be rollers, gears, or other designs. The (typically metal) rolling elements themselves will require lubrication - either periodically or through a Sealed Bearing design (see below).

- Sleeve Bearings (Also Called “Journal” or “Plain” Bearings): In this design, the journal simply slides over the bearing surface with no additional mechanical element. New low-friction, self-lubricating options have rendered sleeve bearings useful across a variety of demanding applications that previously required a rolling-element design.

A Note on Plain v. Plane Bearings: There’s Nothing “Plain” About Them

You will notice that many industry sources refer to sleeve/journal bearings as “plain” rather than “plane,” as we refer to them at TriStar.

We think this distinction helps highlight the fact “plain” bearings are by no means relegated to simple or low-load applications.

The “Plane bearing” term focuses on the geometric properties of the bearings rather than the mechanical complexity of the underlying mechanism. Low-friction, self-lubricating plastics mean that the presence of rolling elements is no longer a hard-guide to a bearing’s potential applications.

Overview of Bearing Types

Plane Bearings: Sleeve, Journal, Bushing

You can think of a plane bearing as a bearing in its simplest form: any non-rolling element that is incorporated where two surfaces rub together is a plane bearing. Common types include sleeve bearings and flange bearings (see below for more on both).

“Journal Bearing,” “Sleeve Bearing,” and “Bushing” are all roughly equivalent terms that are used by different industries to describe the same basic design concept.

Sleeve Bearings

What is a sleeve bearing?

A sleeve bearing is the simplest design of plane bearing, consisting of a smooth sleeve that is fitted between an axle and bore. Typically, some sort of liquid or particulate lubricant will sit between the journal and axle.

A sleeve bearing is the simplest design of plane bearing, consisting of a smooth sleeve that is fitted between an axle and bore. Typically, some sort of liquid or particulate lubricant will sit between the journal and axle.

Sleeve Bearings v. Bushing

A “bushing” is a closely related classification that can sometimes risk introducing confusion.

The formal definition of a bushing is a thin sleeve or tube which constrains relative motion. But how is this different from a sleeve bearing? It isn’t, necessarily. Some industries simply use the term “bushing” as a quirk of history. In general, we find that a bushing will always refer to a single-component sleeve.

Sleeve Bearing Applications

Sleeve bearings are a versatile component employed in just about every sort of design imaginable. Just a few examples include:

- Automotive – Transmission shafts, links, pins and crank components

- Agriculture – Linkage assemblies on attachments, steering gear

- Off-road – Clevis bearings for hydraulic cylinder pins

- Marine – Steady bearings for driveshafts

- Food Processing & packaging – Conveyor and filling devices.

Flange Bearings

This design adds a “flange,” or protruding rim, as a locating mechanism which holds the attached sleeve in place. This flange is attached to a mounting surface that runs perpendicular to the bearing shaft. This additional support is critical in applications with high speeds, heavy loads, or extensive vibration/movement.

This design adds a “flange,” or protruding rim, as a locating mechanism which holds the attached sleeve in place. This flange is attached to a mounting surface that runs perpendicular to the bearing shaft. This additional support is critical in applications with high speeds, heavy loads, or extensive vibration/movement.

Thrust Bearings

In its simplest form, you can think of a thrust bearing as simply a washer. Formally, a thrust bearing provides a bearing for forces that act axially to the shaft. A prototypical example is a propeller shaft on aircraft.

In its simplest form, you can think of a thrust bearing as simply a washer. Formally, a thrust bearing provides a bearing for forces that act axially to the shaft. A prototypical example is a propeller shaft on aircraft.

Like other bearing types, thrust bearings can employ a rolling element, with balls or rollers supported inside a ring. Low-friction plastics offer analogous benefits to those they offer in linear or rotational applications: the right materials can withstand axial force with reduced need for lubrication.

Linear Bearings

What is a linear bearing?

A linear-motion bearing (sometimes called a “linear slide”) provides free motion along a defined path.

A linear-motion bearing (sometimes called a “linear slide”) provides free motion along a defined path.

This linear motion contrasts with the rotational motion of the prototypical bearing design described earlier in the article. Like a rotational bearing, a linear bearing can be extremely simple--like a wooden desk drawer resting on a wooden slide track. But more complex linear bearing designs allow for less friction, faster motion, and more precise control over range-of-motion.

Examples of linear bearings include everything from desk-drawer slides to seismic shock absorbers that help protect buildings from earthquakes.

How do linear bearings work?

In the most common arrangement, a bearing travels along a square rail- or round rod- guide.

A rail provides a track which a linear bearing moves along. The shape and design of this rail may vary depending on how loads will be borne in the intended application. As with, for instance, a curving train track, this rail does not need to be in a straight line.

The rail-mounted bearing mechanism is known as a “carriage” or “block.” The point of contact between the carriage and the rail is known as the “race.”

As with a rotational bearing, friction is generated between these two parts. This friction can either be dissipated with some combination rolling elements, lubrication, and low-friction/self-lubricating plastic sleeves.

In general, all of the bearing design elements we explore in this article apply to linear bearings as well, including seals, lubrication, and self-lubrication options.

For instance, an oil-infused bronze sleeve is one common low-load design; a simple example is a slide-out track for a drawer. More demanding applications begin necessitating more complex mechanisms. Some linear bearings designs even incorporate a wiper mechanism in front of the bearing to clear dirt and debris from the rail and limit contamination.

What are linear bearings used for?

Linear bearing applications are as broad as those of rotational bearings. They range from simple furniture drawers up to roller-coasters and high-performance machine tools that require extremely precise motion-regulation.

Flanged Linear Bearings

In this design, a small rib-like structure protrudes from the bearing, fitting in with a corresponding notch/indentation in the rail. This flange guides the bearings along the rail while limiting contact points.

Sealed Linear Bearings

As with other bearing designs, linear bearings can be sealed off using metal or rubber. This practice reduces contamination and prevents lubrication leakage: see Sealed Bearings, below.

Sealed Bearings

Sealed bearings have lubrication injected during the manufacturing process and are then sealed off. They are designed to both:

Sealed bearings have lubrication injected during the manufacturing process and are then sealed off. They are designed to both:

- Prevent lubricant from escaping the bearing mechanism.

- Prevent contaminants from entering the bearing mechanism.

The seal is not necessarily permanent. Many bearings, for instance, employ a rubber seal that can be readily removed for maintenance (lubrication/cleaning) as necessary.

Like the journal itself, the bearing seal material needs to be carefully calibrated to pressure, temperature, and service life requirements. Selecting the proper seal material and design will maximize seal-life.

What is a Sealed Bearing Used For?

Generally, sealed bearings are used to in conditions where either frequent re-lubrication is impractical, or dust/dirt contamination is a prime consideration.

Sealed Bearings vs Open Bearings: When to Use Sealed Bearings

The main advantage of open bearing designs is cost and ease of access for maintenance.

If frequent maintenance is planned, the additional costs of a sealed design may not be worthwhile.

In other environments, however, like those full of particulate matter from a manufacturing operation, employing seals (or self-lubricating bearings ) may be a virtual necessity.

Metal Sealed Bearings

Metal-sealed bearings are typically the cheapest sealed bearing options but are harder to access for maintenance.

Rubber Sealed bearings

Rubber-sealed bearings are typically more expensive than metal-sealed but can be more easily opened for re-lubrication. They cannot operate in particularly high temperatures, however.

Polymer Sealed Bearings

As with bearings themselves, plastic polymers (PTFE in particular) are opening up new frontiers for seals with superior performance characteristics.

Polymer seals, for instance, can stand up to more heat than rubber seals while offering improved corrosion- and chemical resistance compared to metal seals (this is important in any application where harsh cleaning chemicals risk damaging the quality of the seal, affecting its performance and lifespan).

Why Do Bearings Fail?

To really understand bearing selection, it’s important to first understand how they can fail. While the underlying function is always similar, different bearing types proliferate because different applications and operating environments place very different stresses on bearings.

Bearings fail prematurely due to damage from common issues like inadequate lubrication, particulate or corrosive contamination, overload, and improper installation. The precise causes of these issues can vary widely depending on the material used and the operational environment.

Meanwhile, the operational and cost implications of bearing failure/maintenance/replacement can vary widely between applications. For a piece of manufacturing equipment that has to be stopped daily for an inspection, for instance, frequent lubrication or occasional bearing replacement may be a non-issue. In these situations, the added cost of more advanced solutions may offer few advantages. But for applications at the other extreme (like bearings for satellites) may need to succeed in conditions where they will never be maintained.

We drive into key factors that can cause bearing failure in more detail below.

Key Drivers of Bearing Failure:

- Foreign Matter: Foreign particles including dirt, grit, lint, dust, and metal shavings, can all cause wear in bearings. Foreign matter is a working fact of some operating environments, and improper sealing can further contribute to unnecessary levels of abrasive particulate.

- Improper Mounting:

- Mounting using pressure to the outer race can cause denting.

- A loose shaft-fit can cause rotation of the shaft within the inner ring. This undesirable rotation produces heat and particulate matter that will wear down bearings. A loose housing can cause similar issues.

- Shafts/Housings fitted too tightly can cause rings to crack, cause internal preloading, and drive unduly high operating temperatures.

- A rough finish on the bearing seat will ultimately lead to breakdown resulting in the loose fit issue described above.

- Misalignment: Issues like bent shafts and out-of-square shaft shoulders/clamping nuts cause high temperatures and separator failure.

- Vibration Brinelling: Vibration forms indentations also (known as “false brinelling”) which prevent normal rotation of the bearing. This lack of rotation prevents fresh lubricant from reaching these indentations, causing material to wear away. Unlike “true brinelling,” a bearing damaged by vibrations isn’t necessarily under excessive load.

- Electrical Damage: Electricity passing through a bearing will result in arcing and burning. This results in damage like pitting and cratering if currents are large enough. Even a low current can create small burns that create fluting over time wherever the current passes through. This fluting can cause melting, early spalling, and excessive noise.

- Poor Lubrication: Inadequate lubrication can cause overheating and excessive wear. Improper maintenance, leakage, oxidation, and atmospheric environment can all contribute to a lack of appropriate lubrication.

- Bearing Fatigue: Excessive load repeated over time can cause metal fatigue. Rolling elements create a wave in contacting material as they roll. This constantly rolling load puts the material in rapidly alternating tension and compression, which will cause damage over time, including brinelling.

- Bearing Corrosion: Bearings can be corroded by contaminates like water and acid, causing abrasive damage over time.

- High Temperatures: a particular concern for plastic bearings, high temperatures can cause bearings to melt and deform over time.

- Poor Storage Conditions: Improper storage conditions can harm bearings before they are put into use—like moist storage conditions causing rust.

When thinking about bearing failure it's also worth learning what signs to look for to indicate that a bearing is getting ready to fail.

Environmental Impact on Bearings

The relative importance of the failure modes discussed above can vary widely depending on where a bearing is employed and how often it can be cost-effectively replaced or accessed for maintenance.

Environmental effects can alter a bearing’s expected lifespan by up to 90%. With this magnitude of environmental lifespan differential, selecting the right bearing for the right environment is instrumental to a design’s ultimate performance and reliability.

A few concise examples below demonstrate how bearings need to be carefully selected to reflect the conditions where they will be expected to operate.

Bearings for Environments with Dust Contamination

Environments like steel mills, construction sites, and food processing lines include high levels of dust and other matter that can contaminate a bearing. Bearings that operate in these environments need to be sourced with this contamination risk in mind: particulates ranging from food debris to metal shavings become abrasive as they build up over time. This abrasion will affect both bearing seals (letting in more particles and/or water over time) and the bearings themselves.

Environments like steel mills, construction sites, and food processing lines include high levels of dust and other matter that can contaminate a bearing. Bearings that operate in these environments need to be sourced with this contamination risk in mind: particulates ranging from food debris to metal shavings become abrasive as they build up over time. This abrasion will affect both bearing seals (letting in more particles and/or water over time) and the bearings themselves.

You can read more about using bearings in dusty environments in our article here.

Bearings for Dirty Environments

The dust contamination discussed above becomes worse as more grease accumulates inside a bearing. As lubricants become contaminated, their abilities to dissipate heat and reduce friction are sharply reduced. At best, bearing life is shortened. At worst, this contamination is a recipe for unplanned failures and downtime.

This makes regular cleaning of lubricated bearings essential—a key design concern for bearings that are difficult to access, will be maintained infrequently, or that operate in environments too dirty to be practically cleaned at required intervals.

While self-lubricating bearings may still require some level of lubrication, their reduced lubrication need creates key maintenance advantages for dirty operating environments

Bearings in Vacuum Environments

Vacuum environments tend to not only introduce maintenance difficulties but unique modes of failure. Plastic bearings, for instance, are often preferred in designs that need to function in vacuums to eliminate lubrication requirements. But plastics need to be carefully selected for vacuum-use: some plastics exhibit out-gassing and particulate-shedding that cannot be easily vented in a vacuum.

Leakage as Failure: A Clean Environment

Any bearing requiring regular lubrication comes with the risk of lubricant contaminating the surrounding environment. When facing design requirements for clean operation (stemming from ISO standards, government regulations, or client demands for sustainable best practices), leakage effectively becomes a mode of bearing failure. With this risk in mind, self-lubricating plastic bearings offer important advantages for clean operation in these environments.

Types of Bearing Materials

Wood Bearings

Wood may not be the first material you think of for bearings, and it is relegated to specialty applications today. But wood bearings provide useful historical context: they illustrate that engineers have been carefully selecting materials to fit bearing performance criteria for much of recorded history.

There is evidence that Phoenician boat builders have been using wooden bearings for rudders as early as 4500 years ago. The right woods are corrosion resistant, allowing them to thrive in submerged applications like rudders or propellers shafts. In the old-world, the ultra-hard wood Lignum Vitae was a popular choice--it’s natural oils provided built-in lubrication while its extreme density helped it hold up under stress. Later, bearing makers would impregnate wooden bearings with animal oils to achieve a similar self-lubricating effect.

Today, composites offer key performance advantages over wood in underwater applications, but wooden bearings were the first example of a bearing material being carefully selected for desirable mechanical properties.

Bronze Bearings

Bronze is a commonly used material that comes in a huge variety of different alloys and compositions--this variety makes bronze a popular choice of bearing material, as a material very close to the precisely desired specification can be sourced. Bronze bearings have strong characteristics for shock, impact, and corrosion resistance.

Bronze bearings do require lubrication both at installation and during operation, which can make them a poor choice for designs that are difficult to access for frequent maintenance. This limitation is why replacing bronze bearings with a self-lubricating option (see below) offers an attractive proposition for many companies.

Stainless Steel Bearings

A common traditional choice for industrial applications, steel bearings can handle extremely high loads and high rpms. Stainless steel bearings offer improved corrosion resistance compared to other steel grades, but potential drawbacks still include relatively high weight and high-noise.

Cast Iron Bearings

Another common traditional choice, cast iron bearings have a sufficiently low friction coefficient to be employed on a steel shaft. Case iron glazes over time which helps reduce wear.

Plastic Bearings

Since emerging in the 1950’s, plastic bearings have become an increasingly viable alternative to traditional metal designs. The benefits of this alternative depend on the precise material in question: performance characteristics vary widely between different plastic formulations/compositions.

Since emerging in the 1950’s, plastic bearings have become an increasingly viable alternative to traditional metal designs. The benefits of this alternative depend on the precise material in question: performance characteristics vary widely between different plastic formulations/compositions.

For simply molded plastic bearings, this benefit may simply be cost. But advanced engineered plastic polymers and composites also offer real performance advantages over metal and other materials. With lower friction and self-lubricating capabilities (more on this below), plastic polymers allow plane bearings to operate effectively in many applications that historically required a rolling-element bearing.

Common plastic types suitable for bearing applications include:

- Phenolics: a composite material made from a filler bonded with phenolic resin. Excellent strength and corrosion resistance; low thermal conductivity necessitates extensive lubrication.

- Acetals: commonly used for cost-effective bearings in a broad array of applications.

- Nylon: quiet operation, low friction, and no lubrication requirements, but relatively low maximum temperature before distortion.

- UHMWPE (Ultrahigh-Molecular-Weight polyethylene): abrasion-resistant and low-friction, this material is a common high-performance replacement for acetal/nylon.

- PTFE (Polytetrafluoroethylene): Popularly known by the trademarked name of Teflon, this synthetic fluoropolymer of tetrafluoroethylene is used in a wide variety of applications--such as coating non-stick pans.

For bearings, PTFE is not only useful as a structural material but as a lubricating medium for self-lubricating bearings (more on this below).

Useful properties include low friction coefficient, corrosion resistance, low electrical conductivity, hydrophobia, and a broad range of tolerable temperatures.

So which of these plastics is best? As with the other bearing selection parameters discussed in this article, it all depends on the application. In fact, these plastics can be blended with one another, or with non-plastic materials, to generate the desired characteristics in terms of performance, maintenance needs, and cost.

For a detailed look at the properties of different plastic polymer offerings from TriStar, take a look at our materials database here.

Key advantages of plastic polymer bearings include:

- Reduced lubrication requirements via lower friction coefficients.

- Increased resistance to contaminants including dust, water, and manufacturing particulate.

- Improved corrosion and rust resistance.

- No grease means cleaner operation, better resistance to debris, and less maintenance.

- Substantially increased life-span (often longer than that of the device it is incorporated in).

- High-sanitation options available for industry-specific needs/regulatory compliance (FDA, USP, 3A, ABS).

- Flexible usage across linear, oscillating, and rotary applications.

Self-Lubricating Bearings

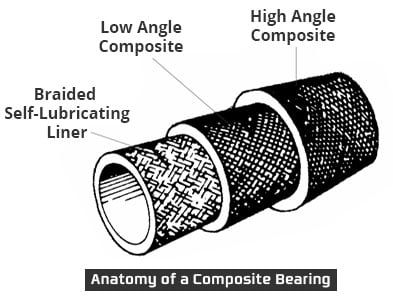

These bearings have a lubricant like PTFE, graphite, or silicon integrated with the rubbing surface of the bearing itself. As moving parts rub together, this lubricant dynamically disperses over time.

These bearings have a lubricant like PTFE, graphite, or silicon integrated with the rubbing surface of the bearing itself. As moving parts rub together, this lubricant dynamically disperses over time.

Self-lubricating plastic polymer bearings utilize two different mechanisms to transfer lubrication media:

- Smearing systems: PTFE-based or PTFE-infused polymers are the most common example of a smearing system. The lubricant needs to find its way out of the polymer and deposit itself into the micro-finish of the contacting surface. This deposit builds up to generate a hydrodynamic film which provides effective lubrication.

- Debris systems: this approach relies on the toughness of the polymer itself (UHMW, Cast Nylon) to knock loose resin micro-particles which effectively function as tiny ball bearings. This approach is generally less efficient but still has an important role in many applications.

Employing one of these designs is important in applications where frequent re-lubrication is impractical or unduly costly, in extremely high-friction environments, or in environments where traditional liquid lubricants represent too great a risk for contamination/leakage.

Because inadequate lubrication is the number-one cause of bearing failure, ending the need for lubrication not only simplifies maintenance but dramatically reduces premature wear that accumulates during inevitable maintenance intervals. Grease and other lubricants also exacerbate contamination issues by helping dust and dirt stick in the bearing mechanism, another long term wear-driver that self-lubricating options eliminate.

Key Advantages of Self-Lubricating Bearings

- Excellent corrosion and wear resistance.

- Lower maintenance cost due to reduced lubrication requirements.

- Lower-friction coefficient.

- Function in high/low-temperature environments.

- Cleaner, grease-less operation.

Rulon®

TriStar is the exclusive North American distributor of Rulon, a family of PTFE-based plastics purpose-built for the functional requirements of demanding applications like bearings. Like other plastics, it is available in a wide variety of formulations (in fact, over 300).

For a deeper look at Rulon and some key formulation options, please see our white paper:

Advanced Self-Lubricating Metal-Backed Solutions

More advanced approaches to metal bearing design allow for self-lubricating capabilities while retaining some of metal’s desirable structural characteristics.

More advanced approaches to metal bearing design allow for self-lubricating capabilities while retaining some of metal’s desirable structural characteristics.

TriStar’s TriSteel™, for instance, consists of a special polymer lining with a metal backing. The liner is impregnated into a sintered porous bronze inter-layer. Both materials can be precisely specified depending on the application. This design takes advantage of steel (zinc/copper-plated or stainless) for structural and mechanical support while utilizing a polymer liner for improved wear characteristics and self-lubrication.

Latest news

-

Spherical Bearing Installation

NewsJun.11,2025

-

Sphere Bearing Applications About Key Uses

NewsJun.11,2025

-

Long-Lasting Bearing Options

NewsJun.11,2025

-

Deep Groove Ball Bearing Basics

NewsJun.11,2025

-

Comprehensive Guide to Zirconia Bearing Testing

NewsJun.11,2025

-

Ceramic Bearing Selection Guide

NewsJun.11,2025