Jun . 26, 2024 08:53 Back to list

Exploring High-Quality 18mm Spherical Bearings Top Manufacturers' Offerings

The Evolution of 18mm Spherical Bearings A Manufacturers' Perspective

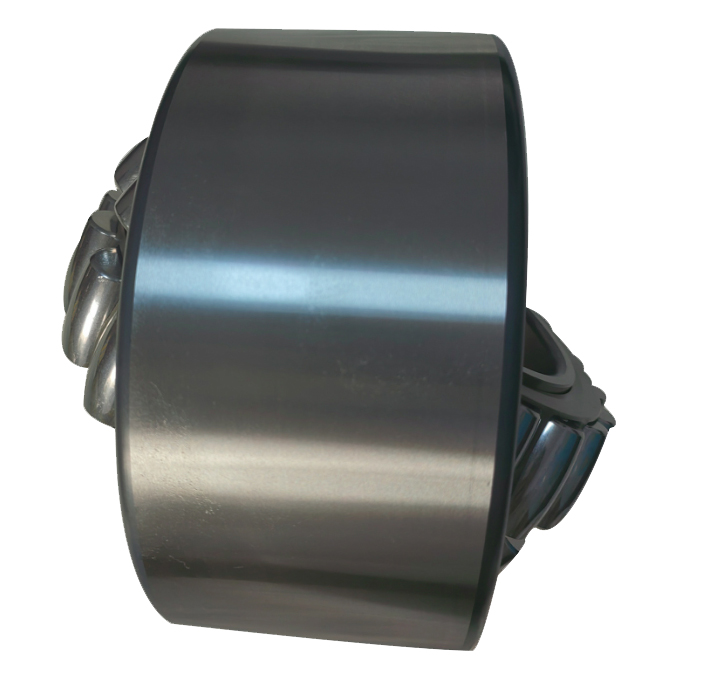

In the realm of precision engineering and industrial machinery, the humble 18mm spherical bearing plays a crucial role in ensuring smooth operation and longevity. As a key component, these bearings have evolved significantly over the years, driven by advancements in manufacturing techniques and the relentless pursuit of performance optimization.

Manufacturers of 18mm spherical bearings, such as SKF, FAG, NSK, and NTN, among others, have been at the forefront of this evolution. Their expertise lies not only in the design but also in the production process, which has become increasingly sophisticated. From raw material selection to the final assembly, every step is meticulously executed to guarantee high-quality bearings that meet international standards.

The initial focus was on improving bearing life, which was primarily determined by the use of high-grade steel alloys and advanced heat treatment processes. Modern manufacturers now employ computer-aided design (CAD) and finite element analysis (FEA) to optimize bearing geometry, enhancing load-carrying capacity and reducing stress points.

Another significant development has been the introduction of precision grinding and lapping technologies. This ensures that the bearing's surface finish is impeccable, minimizing friction and wear, thus extending the bearing's operational lifespan. Moreover, the integration of lubrication systems, like grease or oil, has improved efficiency and reduced maintenance requirements.

Environmental sustainability has also become a major concern for manufacturers. Many now produce bearings using eco-friendly materials and processes, while incorporating features that facilitate easy recycling Many now produce bearings using eco-friendly materials and processes, while incorporating features that facilitate easy recycling Many now produce bearings using eco-friendly materials and processes, while incorporating features that facilitate easy recycling Many now produce bearings using eco-friendly materials and processes, while incorporating features that facilitate easy recycling

Many now produce bearings using eco-friendly materials and processes, while incorporating features that facilitate easy recycling Many now produce bearings using eco-friendly materials and processes, while incorporating features that facilitate easy recycling 18mm spherical bearing manufacturers. This not only contributes to a greener future but also adds value to their product offerings.

Quality control is another area where 18mm spherical bearing manufacturers excel. Rigorous testing, including load-bearing capacity tests, speed endurance, and thermal stability checks, are conducted to ensure the bearings consistently meet or exceed customer expectations. Certifications like ISO 9001 further validate their commitment to quality.

In today's fast-paced market, customization has become a key differentiator. Manufacturers cater to diverse industries by offering bearing solutions tailored to specific applications, from aerospace to automotive, robotics, and heavy machinery. They provide technical support and engineering services to help customers maximize the potential of their bearings in real-world scenarios.

In conclusion, the 18mm spherical bearing manufacturers have transformed from simple suppliers to innovative problem solvers. Their continuous efforts in research, technology, and sustainability reflect a dedication to excellence in the industry. As we look forward, the future of these bearings promises even more advancements, pushing the boundaries of performance and reliability.

18mm spherical bearing manufacturers. This not only contributes to a greener future but also adds value to their product offerings.

Quality control is another area where 18mm spherical bearing manufacturers excel. Rigorous testing, including load-bearing capacity tests, speed endurance, and thermal stability checks, are conducted to ensure the bearings consistently meet or exceed customer expectations. Certifications like ISO 9001 further validate their commitment to quality.

In today's fast-paced market, customization has become a key differentiator. Manufacturers cater to diverse industries by offering bearing solutions tailored to specific applications, from aerospace to automotive, robotics, and heavy machinery. They provide technical support and engineering services to help customers maximize the potential of their bearings in real-world scenarios.

In conclusion, the 18mm spherical bearing manufacturers have transformed from simple suppliers to innovative problem solvers. Their continuous efforts in research, technology, and sustainability reflect a dedication to excellence in the industry. As we look forward, the future of these bearings promises even more advancements, pushing the boundaries of performance and reliability.

Many now produce bearings using eco-friendly materials and processes, while incorporating features that facilitate easy recycling Many now produce bearings using eco-friendly materials and processes, while incorporating features that facilitate easy recycling

Many now produce bearings using eco-friendly materials and processes, while incorporating features that facilitate easy recycling Many now produce bearings using eco-friendly materials and processes, while incorporating features that facilitate easy recycling 18mm spherical bearing manufacturers. This not only contributes to a greener future but also adds value to their product offerings.

Quality control is another area where 18mm spherical bearing manufacturers excel. Rigorous testing, including load-bearing capacity tests, speed endurance, and thermal stability checks, are conducted to ensure the bearings consistently meet or exceed customer expectations. Certifications like ISO 9001 further validate their commitment to quality.

In today's fast-paced market, customization has become a key differentiator. Manufacturers cater to diverse industries by offering bearing solutions tailored to specific applications, from aerospace to automotive, robotics, and heavy machinery. They provide technical support and engineering services to help customers maximize the potential of their bearings in real-world scenarios.

In conclusion, the 18mm spherical bearing manufacturers have transformed from simple suppliers to innovative problem solvers. Their continuous efforts in research, technology, and sustainability reflect a dedication to excellence in the industry. As we look forward, the future of these bearings promises even more advancements, pushing the boundaries of performance and reliability.

18mm spherical bearing manufacturers. This not only contributes to a greener future but also adds value to their product offerings.

Quality control is another area where 18mm spherical bearing manufacturers excel. Rigorous testing, including load-bearing capacity tests, speed endurance, and thermal stability checks, are conducted to ensure the bearings consistently meet or exceed customer expectations. Certifications like ISO 9001 further validate their commitment to quality.

In today's fast-paced market, customization has become a key differentiator. Manufacturers cater to diverse industries by offering bearing solutions tailored to specific applications, from aerospace to automotive, robotics, and heavy machinery. They provide technical support and engineering services to help customers maximize the potential of their bearings in real-world scenarios.

In conclusion, the 18mm spherical bearing manufacturers have transformed from simple suppliers to innovative problem solvers. Their continuous efforts in research, technology, and sustainability reflect a dedication to excellence in the industry. As we look forward, the future of these bearings promises even more advancements, pushing the boundaries of performance and reliability. Latest news

-

CKZ-A Sprag Type Freewheels One Way Clutch - High Performance & Reliable

NewsAug.16,2025

-

ASNU 12-35 NFS TFS Roller Freewheel One Way Clutch Bearings

NewsAug.15,2025

-

Durable AK208 Pillow Block Housing | Reliable Bearing Support

NewsAug.14,2025

-

28.6x80x36.53mm W208PPB5 Heavy Duty Disc Harrow Bearing

NewsAug.13,2025

-

CKZF-B Series Flywheel Backstop Clutch: Reliable Reverse Prevention

NewsAug.12,2025

-

W210PPB6 PEER Square Bore Farm Bearings - Heavy-Duty & Durable

NewsAug.11,2025