Jun . 26, 2024 08:58 Back to list

Exploring Diverse Wholesale Ceramic Bearings A Comprehensive Overview

Wholesale Types of Ceramic Bearings A Comprehensive Overview

In the realm of engineering and industrial applications, ceramic bearings have gained significant traction due to their exceptional performance and durability. As a wholesale supplier, understanding the various types of ceramic bearings is crucial for catering to diverse customer needs. In this article, we will delve into the different categories, advantages, and key features of these innovative bearings.

Ceramic bearings are primarily made from advanced materials like silicon nitride (Si3N4), zirconium oxide (ZrO2), or aluminum oxide (Al2O3), offering unparalleled resistance to wear, friction, and corrosion. Here are the primary types you might encounter in the wholesale market

1. Full-Ceramic Bearings These bearings consist entirely of ceramic materials, providing extremely low friction coefficients, high-temperature resistance, and excellent load-bearing capacity. They are ideal for high-speed, precision, and harsh environment applications.

2. Hybrid Ceramic Bearings A blend of ceramic and metal, hybrid bearings combine the strength of ceramic with the lubrication properties of steel. They offer a balance between durability and cost, making them suitable for medium to high-load scenarios.

3. Ball Bearings Ceramic ball bearings feature lightweight, robust, and chemically inert balls, which reduce energy loss and increase efficiency. These are commonly used in pumps, motors, and precision machinery.

4. Roller Bearings Similar to ceramic balls, ceramic roller bearings employ ceramic rollers within a metallic cage, ensuring smooth and long-lasting operation Roller Bearings Similar to ceramic balls, ceramic roller bearings employ ceramic rollers within a metallic cage, ensuring smooth and long-lasting operation Roller Bearings Similar to ceramic balls, ceramic roller bearings employ ceramic rollers within a metallic cage, ensuring smooth and long-lasting operation Roller Bearings Similar to ceramic balls, ceramic roller bearings employ ceramic rollers within a metallic cage, ensuring smooth and long-lasting operation

Roller Bearings Similar to ceramic balls, ceramic roller bearings employ ceramic rollers within a metallic cage, ensuring smooth and long-lasting operation Roller Bearings Similar to ceramic balls, ceramic roller bearings employ ceramic rollers within a metallic cage, ensuring smooth and long-lasting operation wholesale types of ceramic bearings. They excel in applications where precision and low friction are essential.

5. Thrust Bearings Designed for axial loads, ceramic thrust bearings provide reliable performance in heavy-duty applications due to their self-lubricating nature and resistance to wear.

6. Cylindrical Roller Bearings These bearings utilize cylindrical ceramic rollers that support radial and axial loads. They are commonly found in machinery requiring high speed and low friction.

7. Spherical Roller Bearings With ceramic spherical rollers, the bearing can handle both radial and axial loads, making them ideal for oscillatory or vibratory loads.

When it comes to selecting the right type, factors such as operating temperature, load capacity, speed requirements, and environmental conditions must be taken into account. The benefits of ceramic bearings include reduced maintenance, longer lifespan, and improved system efficiency, making them an attractive choice for many industries.

Wholesale suppliers should stay updated with the latest advancements in ceramic bearing technology to ensure they can cater to the ever-evolving demands of their customers. By offering a comprehensive range of ceramic bearing options, they can contribute to enhancing the performance and reliability of various industrial machines and equipment.

wholesale types of ceramic bearings. They excel in applications where precision and low friction are essential.

5. Thrust Bearings Designed for axial loads, ceramic thrust bearings provide reliable performance in heavy-duty applications due to their self-lubricating nature and resistance to wear.

6. Cylindrical Roller Bearings These bearings utilize cylindrical ceramic rollers that support radial and axial loads. They are commonly found in machinery requiring high speed and low friction.

7. Spherical Roller Bearings With ceramic spherical rollers, the bearing can handle both radial and axial loads, making them ideal for oscillatory or vibratory loads.

When it comes to selecting the right type, factors such as operating temperature, load capacity, speed requirements, and environmental conditions must be taken into account. The benefits of ceramic bearings include reduced maintenance, longer lifespan, and improved system efficiency, making them an attractive choice for many industries.

Wholesale suppliers should stay updated with the latest advancements in ceramic bearing technology to ensure they can cater to the ever-evolving demands of their customers. By offering a comprehensive range of ceramic bearing options, they can contribute to enhancing the performance and reliability of various industrial machines and equipment.

Roller Bearings Similar to ceramic balls, ceramic roller bearings employ ceramic rollers within a metallic cage, ensuring smooth and long-lasting operation Roller Bearings Similar to ceramic balls, ceramic roller bearings employ ceramic rollers within a metallic cage, ensuring smooth and long-lasting operation

Roller Bearings Similar to ceramic balls, ceramic roller bearings employ ceramic rollers within a metallic cage, ensuring smooth and long-lasting operation Roller Bearings Similar to ceramic balls, ceramic roller bearings employ ceramic rollers within a metallic cage, ensuring smooth and long-lasting operation wholesale types of ceramic bearings. They excel in applications where precision and low friction are essential.

5. Thrust Bearings Designed for axial loads, ceramic thrust bearings provide reliable performance in heavy-duty applications due to their self-lubricating nature and resistance to wear.

6. Cylindrical Roller Bearings These bearings utilize cylindrical ceramic rollers that support radial and axial loads. They are commonly found in machinery requiring high speed and low friction.

7. Spherical Roller Bearings With ceramic spherical rollers, the bearing can handle both radial and axial loads, making them ideal for oscillatory or vibratory loads.

When it comes to selecting the right type, factors such as operating temperature, load capacity, speed requirements, and environmental conditions must be taken into account. The benefits of ceramic bearings include reduced maintenance, longer lifespan, and improved system efficiency, making them an attractive choice for many industries.

Wholesale suppliers should stay updated with the latest advancements in ceramic bearing technology to ensure they can cater to the ever-evolving demands of their customers. By offering a comprehensive range of ceramic bearing options, they can contribute to enhancing the performance and reliability of various industrial machines and equipment.

wholesale types of ceramic bearings. They excel in applications where precision and low friction are essential.

5. Thrust Bearings Designed for axial loads, ceramic thrust bearings provide reliable performance in heavy-duty applications due to their self-lubricating nature and resistance to wear.

6. Cylindrical Roller Bearings These bearings utilize cylindrical ceramic rollers that support radial and axial loads. They are commonly found in machinery requiring high speed and low friction.

7. Spherical Roller Bearings With ceramic spherical rollers, the bearing can handle both radial and axial loads, making them ideal for oscillatory or vibratory loads.

When it comes to selecting the right type, factors such as operating temperature, load capacity, speed requirements, and environmental conditions must be taken into account. The benefits of ceramic bearings include reduced maintenance, longer lifespan, and improved system efficiency, making them an attractive choice for many industries.

Wholesale suppliers should stay updated with the latest advancements in ceramic bearing technology to ensure they can cater to the ever-evolving demands of their customers. By offering a comprehensive range of ceramic bearing options, they can contribute to enhancing the performance and reliability of various industrial machines and equipment. Latest news

-

25MM 2 BOLT UCFLX05-14 Flange bearing unit( oval)

NewsMar.07,2025

-

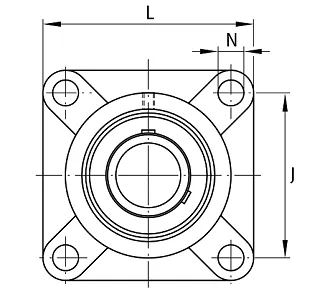

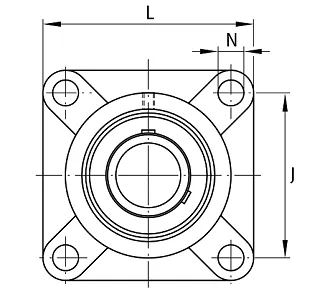

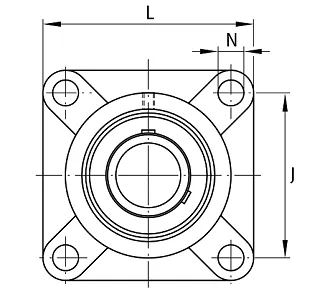

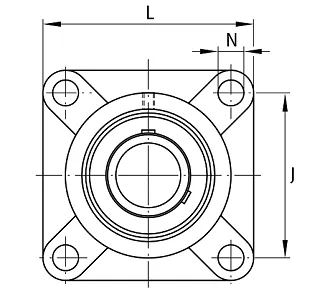

4 bolt UCF 200 series Pillow block bearings

NewsMar.07,2025

-

25MM 2 BOLT UCFLX05-14 Flange bearing unit( oval)

NewsMar.07,2025

-

UCF216-50 4-Bolt Flange Housing Square Bearing

NewsMar.07,2025

-

25MM 2 BOLT UCFLX05-14 Flange bearing unit( oval)

NewsMar.07,2025

-

spherical roller bearing material exporter

NewsMar.07,2025