Jun . 26, 2024 09:12 Back to list

Exploring Advanced Custom Ceramic Bearings for Enhanced Axial Performance

The Advancements and Innovations in Custom Ceramic Axle Bearings

In the realm of engineering and automotive technology, one of the most significant advancements has been the emergence of custom ceramic axle bearings. These innovative components have revolutionized the way vehicles operate, offering unparalleled performance, efficiency, and durability.

Ceramic materials, particularly those made from silicon nitride or yttrium-stabilized zirconia, have been a game-changer in the industry. Unlike traditional steel bearings, which can experience wear, heat expansion, and corrosion, ceramic bearings boast exceptional properties. They exhibit a lower coefficient of friction, resulting in reduced energy loss and increased fuel efficiency. This makes them an ideal choice for high-performance applications, where every fraction of efficiency counts.

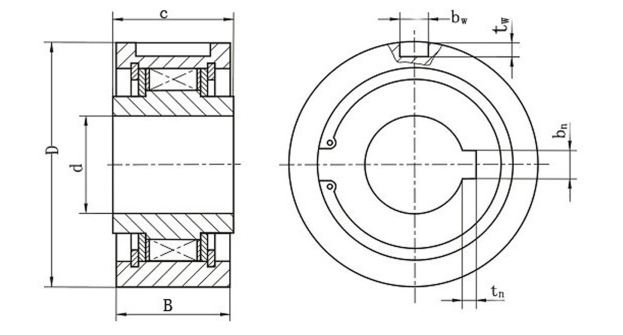

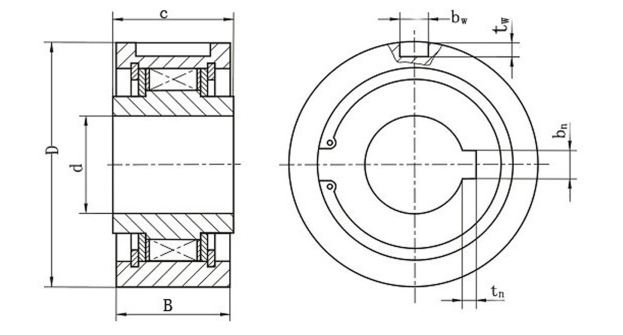

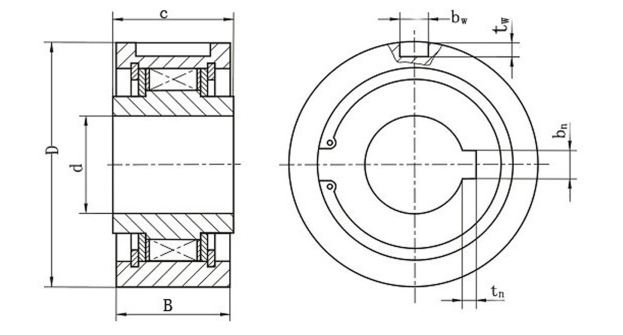

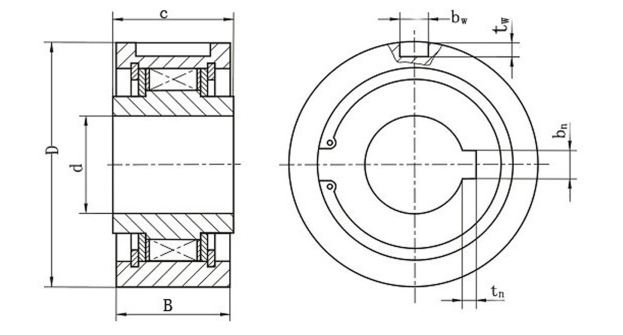

Customization in ceramic bearings is a key aspect that sets them apart. Manufacturers can tailor the size, shape, and even surface finish to meet specific customer requirements. This flexibility allows for optimal fit and function, catering to the unique needs of individual vehicles or extreme sports machinery. It ensures that the bearing's performance matches the demands placed on it, enhancing overall system reliability.

Another advantage of custom ceramic bearings is their lightweight nature. The low density of ceramic materials reduces unsprung weight, improving vehicle handling and acceleration The low density of ceramic materials reduces unsprung weight, improving vehicle handling and acceleration The low density of ceramic materials reduces unsprung weight, improving vehicle handling and acceleration The low density of ceramic materials reduces unsprung weight, improving vehicle handling and acceleration

The low density of ceramic materials reduces unsprung weight, improving vehicle handling and acceleration The low density of ceramic materials reduces unsprung weight, improving vehicle handling and acceleration custom ceramic axle bearings. This is particularly crucial in racing cars and aerospace applications, where every gram counts towards speed and agility.

Moreover, ceramic bearings are known for their resistance to high temperatures and harsh environments. They maintain their integrity under extreme conditions, minimizing the risk of premature failure. This durability translates into longer service life, reducing maintenance costs and downtime for the user.

However, the transition from steel to ceramic bearings is not without challenges. Initial investment in manufacturing processes and cost considerations are factors that need to be addressed. But as technology advances and economies of scale kick in, the cost gap is gradually closing, making ceramic bearings a more accessible option for a wider range of industries.

In conclusion, custom ceramic axle bearings represent a leap forward in engineering prowess. Their unique combination of performance, customization, and durability has the potential to reshape the way we perceive and design mechanical systems. As more industries embrace these innovative bearings, we can expect to see further improvements in efficiency, reliability, and sustainability across various sectors.

custom ceramic axle bearings. This is particularly crucial in racing cars and aerospace applications, where every gram counts towards speed and agility.

Moreover, ceramic bearings are known for their resistance to high temperatures and harsh environments. They maintain their integrity under extreme conditions, minimizing the risk of premature failure. This durability translates into longer service life, reducing maintenance costs and downtime for the user.

However, the transition from steel to ceramic bearings is not without challenges. Initial investment in manufacturing processes and cost considerations are factors that need to be addressed. But as technology advances and economies of scale kick in, the cost gap is gradually closing, making ceramic bearings a more accessible option for a wider range of industries.

In conclusion, custom ceramic axle bearings represent a leap forward in engineering prowess. Their unique combination of performance, customization, and durability has the potential to reshape the way we perceive and design mechanical systems. As more industries embrace these innovative bearings, we can expect to see further improvements in efficiency, reliability, and sustainability across various sectors.

The low density of ceramic materials reduces unsprung weight, improving vehicle handling and acceleration The low density of ceramic materials reduces unsprung weight, improving vehicle handling and acceleration

The low density of ceramic materials reduces unsprung weight, improving vehicle handling and acceleration The low density of ceramic materials reduces unsprung weight, improving vehicle handling and acceleration custom ceramic axle bearings. This is particularly crucial in racing cars and aerospace applications, where every gram counts towards speed and agility.

Moreover, ceramic bearings are known for their resistance to high temperatures and harsh environments. They maintain their integrity under extreme conditions, minimizing the risk of premature failure. This durability translates into longer service life, reducing maintenance costs and downtime for the user.

However, the transition from steel to ceramic bearings is not without challenges. Initial investment in manufacturing processes and cost considerations are factors that need to be addressed. But as technology advances and economies of scale kick in, the cost gap is gradually closing, making ceramic bearings a more accessible option for a wider range of industries.

In conclusion, custom ceramic axle bearings represent a leap forward in engineering prowess. Their unique combination of performance, customization, and durability has the potential to reshape the way we perceive and design mechanical systems. As more industries embrace these innovative bearings, we can expect to see further improvements in efficiency, reliability, and sustainability across various sectors.

custom ceramic axle bearings. This is particularly crucial in racing cars and aerospace applications, where every gram counts towards speed and agility.

Moreover, ceramic bearings are known for their resistance to high temperatures and harsh environments. They maintain their integrity under extreme conditions, minimizing the risk of premature failure. This durability translates into longer service life, reducing maintenance costs and downtime for the user.

However, the transition from steel to ceramic bearings is not without challenges. Initial investment in manufacturing processes and cost considerations are factors that need to be addressed. But as technology advances and economies of scale kick in, the cost gap is gradually closing, making ceramic bearings a more accessible option for a wider range of industries.

In conclusion, custom ceramic axle bearings represent a leap forward in engineering prowess. Their unique combination of performance, customization, and durability has the potential to reshape the way we perceive and design mechanical systems. As more industries embrace these innovative bearings, we can expect to see further improvements in efficiency, reliability, and sustainability across various sectors. Latest news

-

CKZ-A Sprag Type Freewheels One Way Clutch - High Performance & Reliable

NewsAug.16,2025

-

ASNU 12-35 NFS TFS Roller Freewheel One Way Clutch Bearings

NewsAug.15,2025

-

Durable AK208 Pillow Block Housing | Reliable Bearing Support

NewsAug.14,2025

-

28.6x80x36.53mm W208PPB5 Heavy Duty Disc Harrow Bearing

NewsAug.13,2025

-

CKZF-B Series Flywheel Backstop Clutch: Reliable Reverse Prevention

NewsAug.12,2025

-

W210PPB6 PEER Square Bore Farm Bearings - Heavy-Duty & Durable

NewsAug.11,2025