Jun . 12, 2024 09:58 Back to list

Electric motor bearings play a crucial role in smooth operation.

The Vital Role of Electric Motor Bearings in Modern Technology

Electric motor bearings, an essential component in the functioning of electric motors, play a pivotal role in ensuring efficiency, durability, and performance. These bearings, often overlooked in the grand scheme of a motor's operation, are the unsung heroes that facilitate smooth rotations, reduce friction, and withstand immense loads.

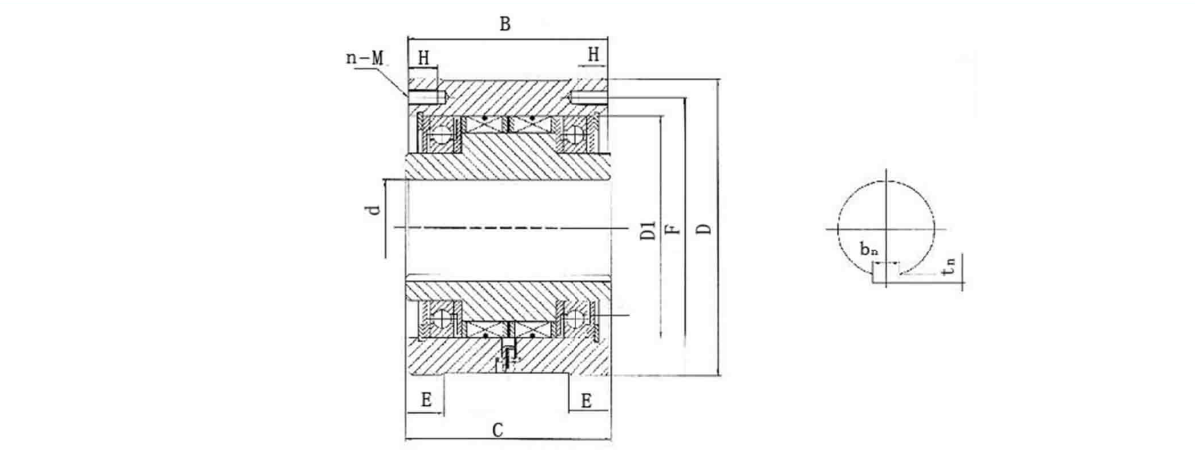

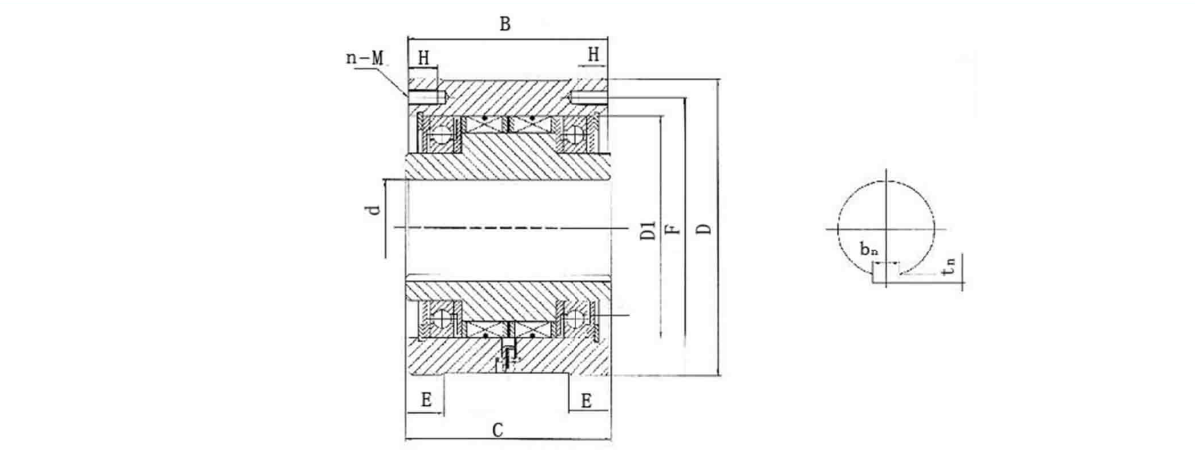

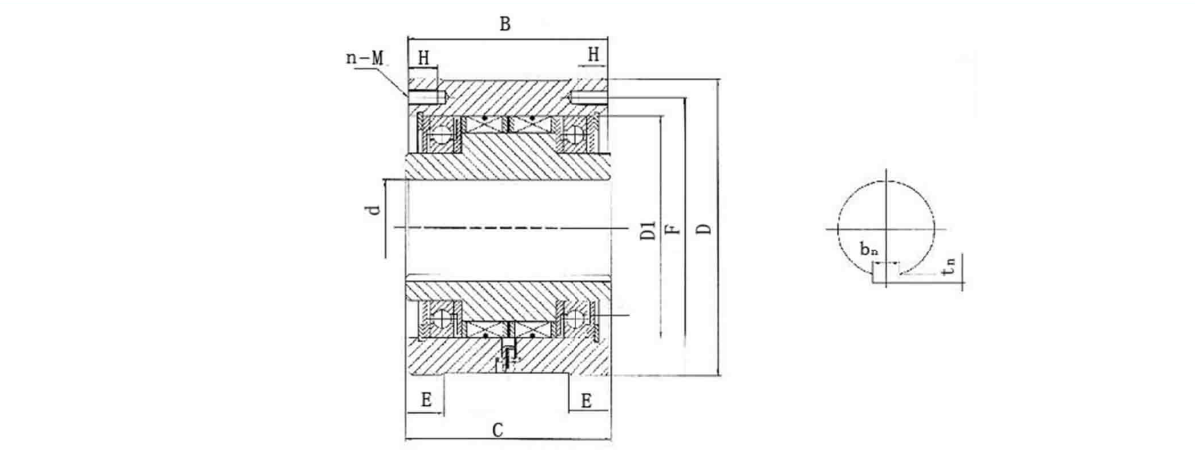

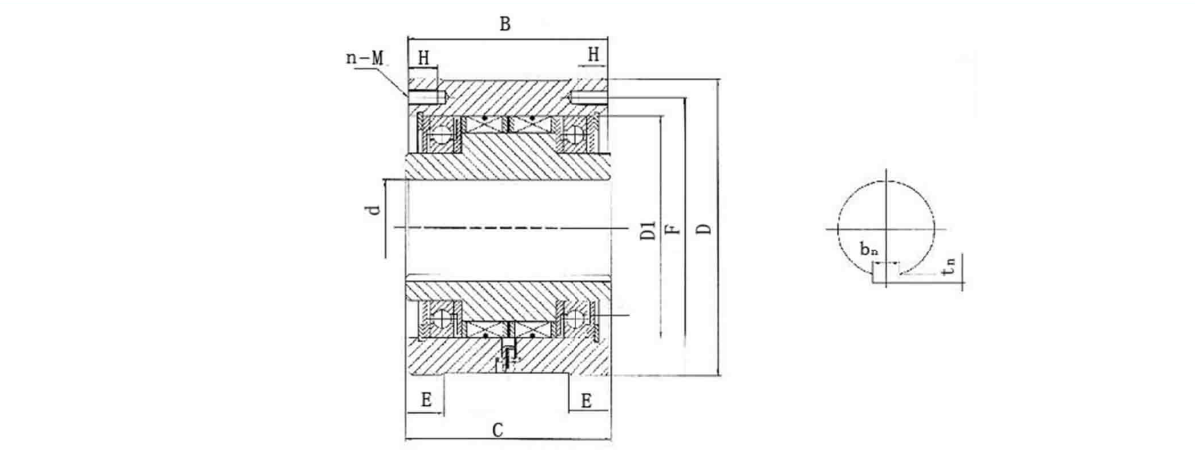

Bearings in electric motors serve as the interface between the stationary and rotating parts. They support the rotor shaft, allowing it to rotate freely while minimizing energy loss due to friction. There are two primary types of bearings commonly used in electric motors ball bearings and roller bearings. Ball bearings consist of small balls that separate the inner and outer races, reducing friction. On the other hand, roller bearings use cylindrical rollers for load distribution, providing higher load capacity than ball bearings.

The selection of the right bearing type is crucial for the motor's overall performance. Factors such as load capacity, speed, temperature, and service life are taken into consideration. For instance, high-speed applications typically require ball bearings due to their lower friction, while heavy-load applications might necessitate roller bearings.

Electric motor bearings also contribute significantly to the motor's efficiency. By minimizing friction, they help convert more of the input electrical energy into mechanical power. This not only enhances the motor's performance but also reduces energy consumption, thereby contributing to sustainability efforts.

Moreover, electric motor bearings are designed to handle both radial and axial loads

Moreover, electric motor bearings are designed to handle both radial and axial loads Moreover, electric motor bearings are designed to handle both radial and axial loads

Moreover, electric motor bearings are designed to handle both radial and axial loads

Moreover, electric motor bearings are designed to handle both radial and axial loads

Moreover, electric motor bearings are designed to handle both radial and axial loads electric motor bearings. Radial loads are perpendicular to the shaft, while axial loads act parallel to it. The ability to manage these loads ensures the motor operates smoothly and prolongs its lifespan.

Despite their robustness, electric motor bearings require regular maintenance and monitoring. Wear and tear, contamination, and overheating can all lead to bearing failure, which can have severe consequences on the motor's functionality. Regular lubrication, cleaning, and inspections are essential to prevent such issues.

Innovations in bearing technology continue to push the boundaries of electric motor performance. Advanced materials, such as ceramic or hybrid bearings, offer improved heat resistance and longer service life. Smart bearings equipped with sensors can provide real-time data on bearing health, enabling predictive maintenance and reducing downtime.

In conclusion, electric motor bearings are the backbone of the motor's operational efficiency and longevity. Their role goes beyond mere support; they are integral to the conversion of electrical energy into mechanical motion. As technology evolves, so do the demands on these bearings, driving continuous advancements in bearing design and materials. Understanding and appreciating the significance of electric motor bearings is crucial for optimizing motor performance and ensuring sustainable operations in various industries.

electric motor bearings. Radial loads are perpendicular to the shaft, while axial loads act parallel to it. The ability to manage these loads ensures the motor operates smoothly and prolongs its lifespan.

Despite their robustness, electric motor bearings require regular maintenance and monitoring. Wear and tear, contamination, and overheating can all lead to bearing failure, which can have severe consequences on the motor's functionality. Regular lubrication, cleaning, and inspections are essential to prevent such issues.

Innovations in bearing technology continue to push the boundaries of electric motor performance. Advanced materials, such as ceramic or hybrid bearings, offer improved heat resistance and longer service life. Smart bearings equipped with sensors can provide real-time data on bearing health, enabling predictive maintenance and reducing downtime.

In conclusion, electric motor bearings are the backbone of the motor's operational efficiency and longevity. Their role goes beyond mere support; they are integral to the conversion of electrical energy into mechanical motion. As technology evolves, so do the demands on these bearings, driving continuous advancements in bearing design and materials. Understanding and appreciating the significance of electric motor bearings is crucial for optimizing motor performance and ensuring sustainable operations in various industries.

Moreover, electric motor bearings are designed to handle both radial and axial loads

Moreover, electric motor bearings are designed to handle both radial and axial loads

Moreover, electric motor bearings are designed to handle both radial and axial loads

Moreover, electric motor bearings are designed to handle both radial and axial loads electric motor bearings. Radial loads are perpendicular to the shaft, while axial loads act parallel to it. The ability to manage these loads ensures the motor operates smoothly and prolongs its lifespan.

Despite their robustness, electric motor bearings require regular maintenance and monitoring. Wear and tear, contamination, and overheating can all lead to bearing failure, which can have severe consequences on the motor's functionality. Regular lubrication, cleaning, and inspections are essential to prevent such issues.

Innovations in bearing technology continue to push the boundaries of electric motor performance. Advanced materials, such as ceramic or hybrid bearings, offer improved heat resistance and longer service life. Smart bearings equipped with sensors can provide real-time data on bearing health, enabling predictive maintenance and reducing downtime.

In conclusion, electric motor bearings are the backbone of the motor's operational efficiency and longevity. Their role goes beyond mere support; they are integral to the conversion of electrical energy into mechanical motion. As technology evolves, so do the demands on these bearings, driving continuous advancements in bearing design and materials. Understanding and appreciating the significance of electric motor bearings is crucial for optimizing motor performance and ensuring sustainable operations in various industries.

electric motor bearings. Radial loads are perpendicular to the shaft, while axial loads act parallel to it. The ability to manage these loads ensures the motor operates smoothly and prolongs its lifespan.

Despite their robustness, electric motor bearings require regular maintenance and monitoring. Wear and tear, contamination, and overheating can all lead to bearing failure, which can have severe consequences on the motor's functionality. Regular lubrication, cleaning, and inspections are essential to prevent such issues.

Innovations in bearing technology continue to push the boundaries of electric motor performance. Advanced materials, such as ceramic or hybrid bearings, offer improved heat resistance and longer service life. Smart bearings equipped with sensors can provide real-time data on bearing health, enabling predictive maintenance and reducing downtime.

In conclusion, electric motor bearings are the backbone of the motor's operational efficiency and longevity. Their role goes beyond mere support; they are integral to the conversion of electrical energy into mechanical motion. As technology evolves, so do the demands on these bearings, driving continuous advancements in bearing design and materials. Understanding and appreciating the significance of electric motor bearings is crucial for optimizing motor performance and ensuring sustainable operations in various industries. Latest news

-

25MM 2 BOLT UCFLX05-14 Flange bearing unit( oval)

NewsMar.07,2025

-

4 bolt UCF 200 series Pillow block bearings

NewsMar.07,2025

-

25MM 2 BOLT UCFLX05-14 Flange bearing unit( oval)

NewsMar.07,2025

-

UCF216-50 4-Bolt Flange Housing Square Bearing

NewsMar.07,2025

-

25MM 2 BOLT UCFLX05-14 Flange bearing unit( oval)

NewsMar.07,2025

-

spherical roller bearing material exporter

NewsMar.07,2025