Mar . 02, 2024 14:42 Back to list

Different Types of Electric Motor Bearings and What They Are Used For

Because the design and uses of electric motors vary across many different industries, there are many different types of bearings used to support them. Here are just a few of them:

Basic Ball Bearings

Basic ball bearings are used for direct coupled applications. These are commonly seen in non-belted applications in electric motors that are under 150 HP. They can handle both radial and axial loads.

Standard Roller Bearings

These bearings are specifically designed for radial loads because they cannot handle axial loads. These are used for belted applications in motors with at least 150 HP.

Angular Contact Ball Bearings

Angular contact ball bearings are designed to handle high axial loads and operate smoothly at high speeds within electric motors. They can be configured in single or double rows and used in many different cage designs.

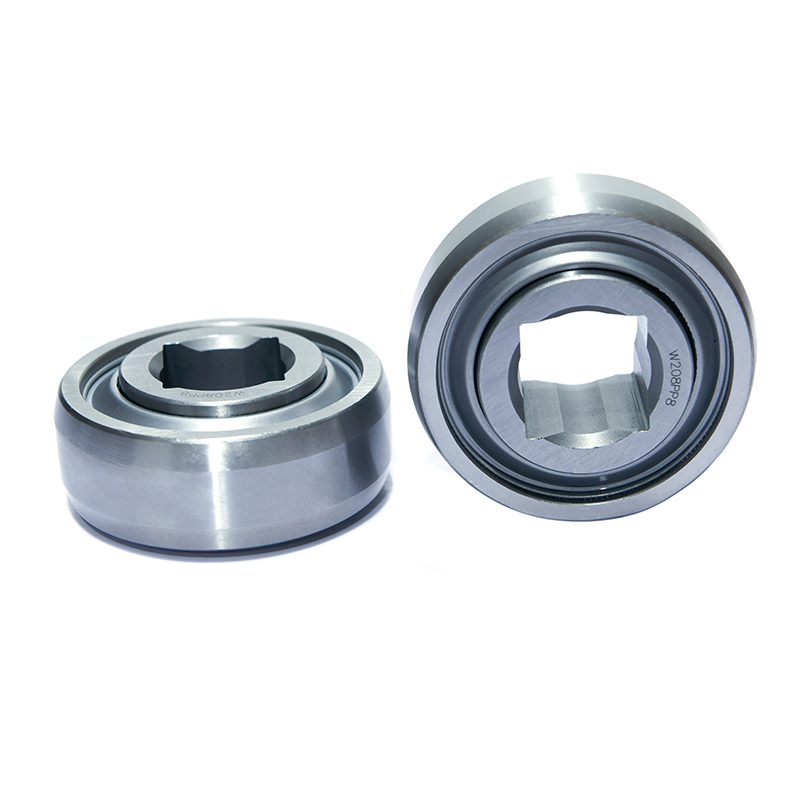

Square Bore W208PP8 Disc Harrow BearingT

Cylindrical Roller Bearings

These roller bearings are what you need when handling extremely high axial loads. They operate efficiently in both medium and high speeds and use several different design configurations. These are used most of the time for belt or gear-driven electric motors.

Deep Groove Ball Bearings

Deep groove ball bearings are some of the most versatile designs for electric motors. With a simple design and a wide range of uses, these bearings are good for high-speed operations with moderate axial and radial loads. These can also be pre-lubricated with seals and shields and are very effective in contaminant-rich environments.

Sealed Bearings

Sealed bearings are a design of bearing that is typically used for smaller motors and designed to limit the bearings’ exposure to contamination. These bearings cannot be re-lubricated with new grease once they have been installed. This means that they have a limited lifespan and should be monitored carefully so that they can be replaced at the first sign of problems.

Shielded Bearings

Shielded bearings are another bearing design used to limit contamination into the rolling elements from the time of installation through the electric motor operation. These can be re-lubricated with packed grease, but if the internal pressure is not relieved, it could lead to forcing the shield against the cage or rolling elements which would create a big problem.

Bearing Design is Important for Electrical Motors

When selecting a motor, one of the factors you must always keep in mind is what type of bearing design works best for the electric motor you are using for this job. If you are not sure what is best for your job in your environment, reach out to an electric motor bearing specialist to figure out which bearing setup and electric motor will work best for you.

Discover premium bearing solutions at Btz Bearing. Our extensive range includes spherical, deep groove, and ceramic bearings tailored for high performance and reliability. Contact us for expert advice and customization options to meet your specific needs.

For inquiries and support, reach out to us at: Phone: 13315937577 Email: Zhang@btzbearing.com, betty@btzbearing.com, Sherry@btzbearing.com, Anne@btzbearing.com

Visit us at No. 3, Area B, Bearing Industry Mass Entrepreneurship Park, Beihuan Road, Linxi County, Xingtai City, Hebei Province, China. Let's drive your project to success together!

Latest news

-

Top Spherical Roller Bearing Material Exporter - High-Performance Alloys

NewsAug.27,2025

-

Durable PLC 110-190 Spherical Roller Bearing for Mixer Reducer

NewsAug.26,2025

-

CSK-2RS Sprag Clutch One Way Bearing: Sealed, High Torque, Durable

NewsAug.25,2025

-

CKZ-D Series One Way Overrunning Clutch: Reliable Power Control

NewsAug.24,2025

-

203KRR3 Round Bore Series Bearings | Cylindrical Outer Ring, Precision

NewsAug.23,2025

-

Top Spherical Roller Bearing Material Exporter - High Performance

NewsAug.22,2025