Among the different types of roller bearings, cylindrical and spherical roller bearings are commonly used. While they share the purpose of facilitating rotational movement, they possess distinct design features and operational characteristics that set them apart. This essay will delve into the key differences between cylindrical and spherical roller bearings, shedding light on their unique properties and applications.

Roller bearings are essential components in various industrial applications, enabling smooth and efficient rotation of shafts and reducing friction.

1. Design And Structure:

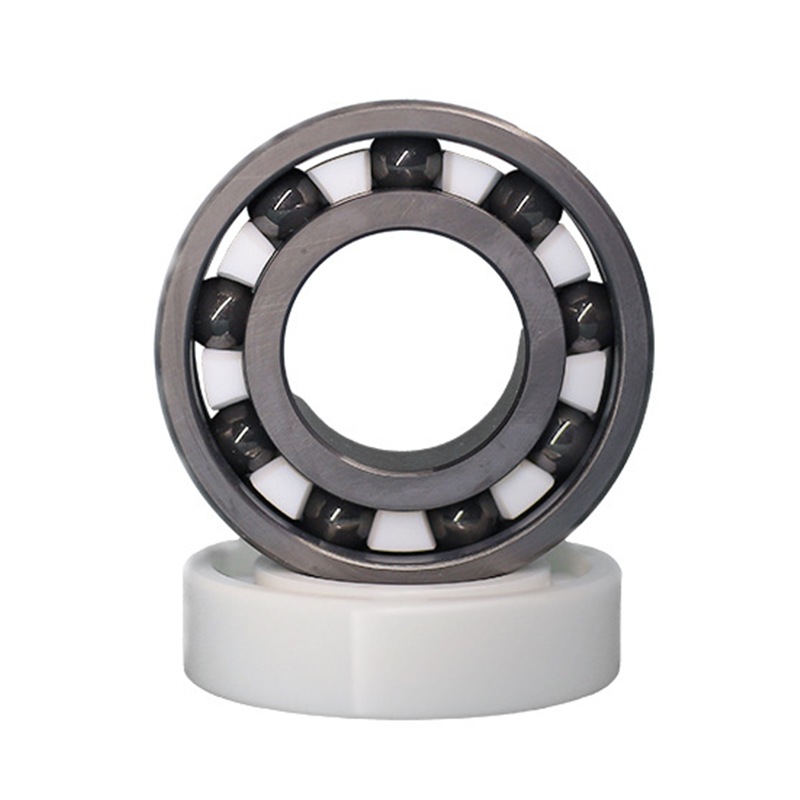

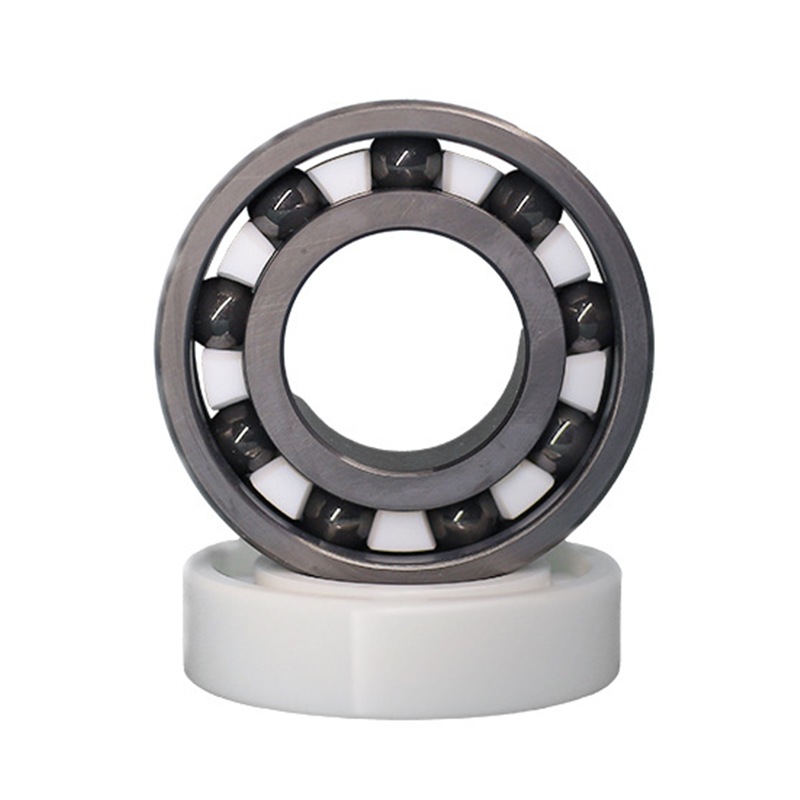

A. Cylindrical Roller Bearings:

Cylindrical roller bearings consist of cylindrical rollers held in place by a cage, which ensures even spacing between the rollers. They are characterized by their high radial load-carrying capacity and relatively low axial load capacity. These bearings have a linear contact with the raceways, allowing them to handle heavy radial loads.

B. Spherical Roller Bearings:

Spherical roller bearings are designed with barrel-shaped rollers arranged on symmetrical spherical raceways. They have two rows of rollers and are capable of accommodating both radial and axial loads. The spherical shape of the rollers enables self-alignment, compensating for misalignments caused by shaft deflections or mounting errors. This design feature makes spherical roller bearings suitable for applications with high shock and vibration.

2. Load Capacity And Performance:

A. Cylindrical Roller Bearings:

Due to their linear contact with the raceways, cylindrical roller bearings excel in handling high radial loads. They are commonly used in applications such as rolling mills, gearboxes, and machine tool spindles. However, their axial load-carrying capacity is relatively limited compared to spherical roller bearings.

B. Spherical Roller Bearings:

Spherical roller bearings are designed to handle both radial and axial loads effectively. The spherical shape of the rollers allows them to accommodate misalignments, reducing stress and enhancing performance. These bearings are commonly employed in heavy-duty applications such as mining equipment, paper mills, and crushers, where they can withstand significant axial and radial loads simultaneously.

3. Misalignment Compensation:

Cylindrical Roller Bearings: Cylindrical roller bearings have limited ability to compensate for misalignments. They rely on precise shaft alignment during installation to ensure optimal performance. Any misalignment can lead to increased friction, reduced bearing life, and potential equipment damage.

A.Spherical Roller Bearings:

Spherical roller bearings possess excellent self-aligning properties, making them ideal for applications with misalignments. They can tolerate angular misalignments caused by shaft deflections or housing deformations, ensuring smooth operation and extended bearing life. This characteristic is particularly valuable in industries where machines are subjected to vibrations, thermal expansion, or uneven loading conditions.

4. Applications:

A. Cylindrical Roller Bearings:

Cylindrical roller bearings find widespread use in various industries, including automotive, aerospace, and manufacturing. They are particularly suitable for applications that involve high radial loads, such as electric motors, pumps, and conveyor systems. Cylindrical roller bearings are also utilized in precision machinery, where their rigidity and accuracy are crucial.

B. Spherical Roller Bearings:

Spherical roller bearings are commonly employed in heavy machinery and equipment operating under challenging conditions. Industries such as mining, construction, and steel manufacturing benefit from their ability to handle high axial and radial loads. Additionally, spherical roller bearings are used in applications that demand misalignment compensation, such as vibrating screens, crushers, and agricultural machinery.

Conclusion:

In summary, the difference between cylindrical and spherical roller bearings lies primarily in their design, load-carrying capacities, and misalignment compensation abilities. Cylindrical roller bearings excel in handling high radial loads, while spherical roller bearings offer superior performance in accommodating both radial and axial loads, as well as compensating for misalignments. By understanding these distinctions, engineers and industries can make informed decisions when selecting roller bearings for specific applications, ensuring