Jun . 26, 2024 15:22 Back to list

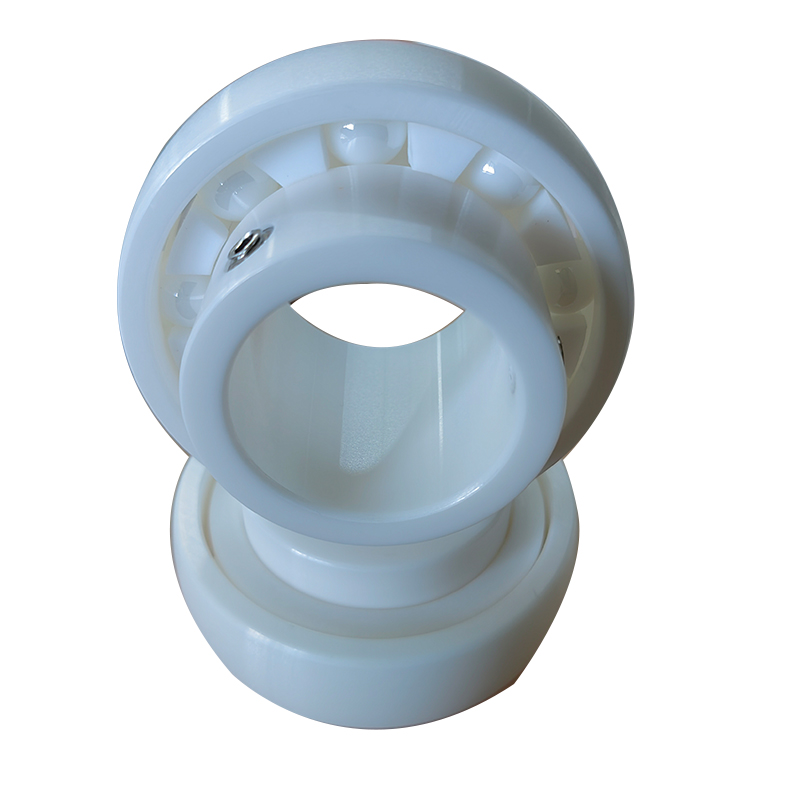

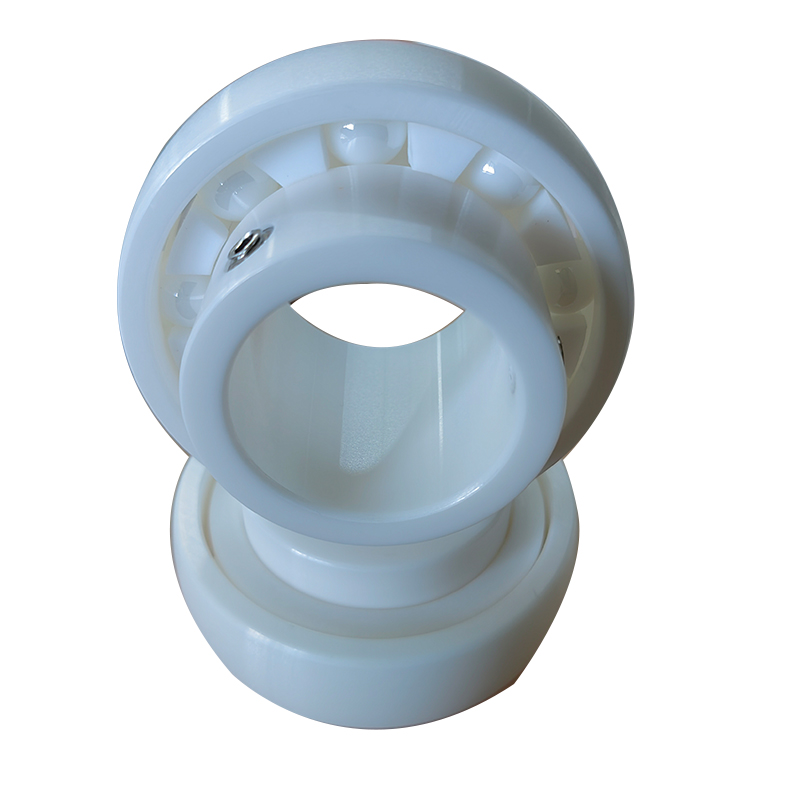

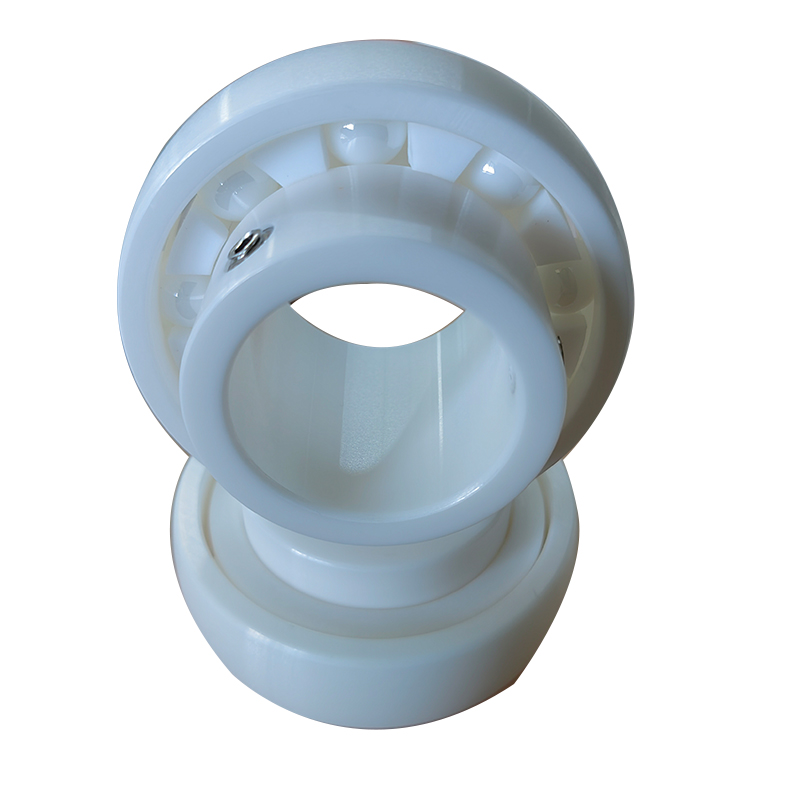

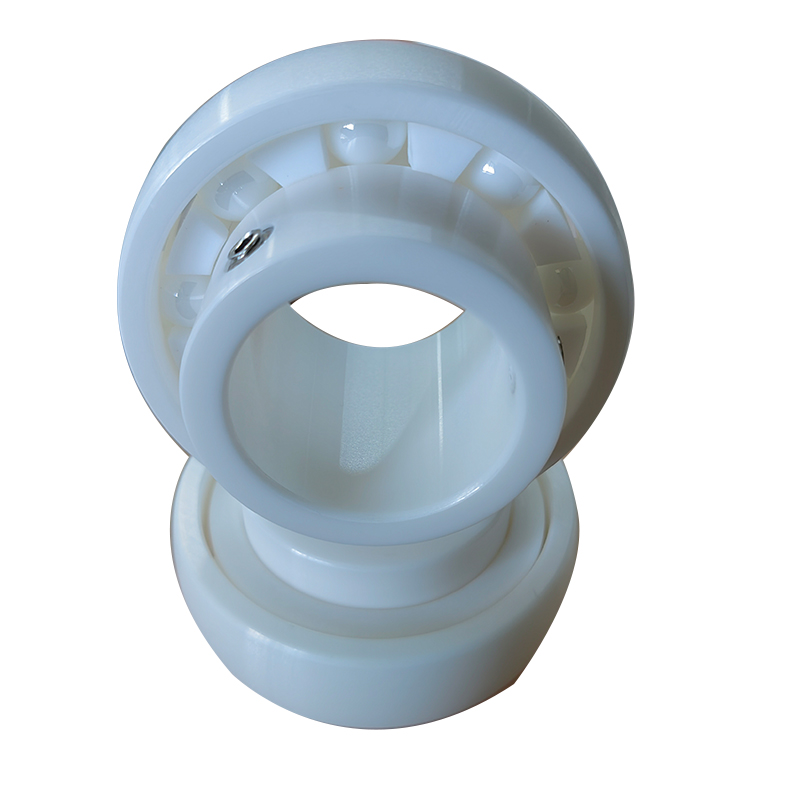

Deep Groove Ball Bearing 6308 Equivalent

Deep Groove Ball Bearings The Ultimate Solution for Precision and Efficiency

Deep groove ball bearings are a type of rolling element bearing that is widely used in various industries due to its excellent performance and reliability. These bearings are characterized by their deep grooves on the inner and outer rings, which provide optimal support and stability to the rotating components. In this article, we will delve into the features, benefits, and applications of deep groove ball bearings, and why they are considered the ultimate solution for precision and efficiency.

Features of Deep Groove Ball Bearings

1. Simplified Structure Deep groove ball bearings have a simple and compact structure, making them easy to install and maintain. They consist of an inner ring, an outer ring, a cage, and steel balls.

2. High Load Capacity Due to their unique design, deep groove ball bearings can withstand high radial and axial loads simultaneously. This makes them suitable for applications where both radial and axial forces are present.

3. Low Friction The rolling elements in deep groove ball bearings have a low coefficient of friction, which reduces energy loss and increases efficiency. This is particularly beneficial in high-speed applications.

4. High Speed Capability Deep groove ball bearings can operate at high speeds without compromising their performance. This is because they have a low heat generation rate and can withstand high temperatures.

Benefits of Using Deep Groove Ball Bearings

1. Improved Efficiency The low friction and high speed capability of deep groove ball bearings result in increased efficiency in machinery and equipment. This leads to reduced energy consumption and lower operating costs This leads to reduced energy consumption and lower operating costs This leads to reduced energy consumption and lower operating costs This leads to reduced energy consumption and lower operating costs

This leads to reduced energy consumption and lower operating costs This leads to reduced energy consumption and lower operating costs deep groove ball bearing 6308.

2. Increased Durability Deep groove ball bearings are designed to withstand harsh operating conditions, such as heavy loads, shock loads, and extreme temperatures. This ensures long-lasting performance and reduces maintenance requirements.

3. Reduced Noise and Vibration The smooth operation of deep groove ball bearings results in reduced noise and vibration in machinery and equipment. This enhances the overall performance and user experience.

Applications of Deep Groove Ball Bearings

1. Industrial Machinery Deep groove ball bearings are commonly used in industrial machinery, such as pumps, fans, compressors, and conveyors, to ensure efficient and reliable operation.

2. Automotive Industry These bearings are widely used in automotive applications, including engines, transmissions, and suspension systems, to improve performance and reduce wear.

3. Aerospace Industry Deep groove ball bearings are essential components in aerospace systems, such as landing gear, flight controls, and engine accessories, due to their high strength and reliability.

4. Electrical Appliances These bearings are used in various electrical appliances, such as washing machines, refrigerators, and air conditioners, to ensure smooth and quiet operation.

In conclusion, deep groove ball bearings are a versatile and reliable solution for precision and efficiency in a wide range of applications. Their unique design and superior performance make them an ideal choice for various industries and mechanical systems.

deep groove ball bearing 6308.

2. Increased Durability Deep groove ball bearings are designed to withstand harsh operating conditions, such as heavy loads, shock loads, and extreme temperatures. This ensures long-lasting performance and reduces maintenance requirements.

3. Reduced Noise and Vibration The smooth operation of deep groove ball bearings results in reduced noise and vibration in machinery and equipment. This enhances the overall performance and user experience.

Applications of Deep Groove Ball Bearings

1. Industrial Machinery Deep groove ball bearings are commonly used in industrial machinery, such as pumps, fans, compressors, and conveyors, to ensure efficient and reliable operation.

2. Automotive Industry These bearings are widely used in automotive applications, including engines, transmissions, and suspension systems, to improve performance and reduce wear.

3. Aerospace Industry Deep groove ball bearings are essential components in aerospace systems, such as landing gear, flight controls, and engine accessories, due to their high strength and reliability.

4. Electrical Appliances These bearings are used in various electrical appliances, such as washing machines, refrigerators, and air conditioners, to ensure smooth and quiet operation.

In conclusion, deep groove ball bearings are a versatile and reliable solution for precision and efficiency in a wide range of applications. Their unique design and superior performance make them an ideal choice for various industries and mechanical systems.

This leads to reduced energy consumption and lower operating costs This leads to reduced energy consumption and lower operating costs

This leads to reduced energy consumption and lower operating costs This leads to reduced energy consumption and lower operating costs deep groove ball bearing 6308.

2. Increased Durability Deep groove ball bearings are designed to withstand harsh operating conditions, such as heavy loads, shock loads, and extreme temperatures. This ensures long-lasting performance and reduces maintenance requirements.

3. Reduced Noise and Vibration The smooth operation of deep groove ball bearings results in reduced noise and vibration in machinery and equipment. This enhances the overall performance and user experience.

Applications of Deep Groove Ball Bearings

1. Industrial Machinery Deep groove ball bearings are commonly used in industrial machinery, such as pumps, fans, compressors, and conveyors, to ensure efficient and reliable operation.

2. Automotive Industry These bearings are widely used in automotive applications, including engines, transmissions, and suspension systems, to improve performance and reduce wear.

3. Aerospace Industry Deep groove ball bearings are essential components in aerospace systems, such as landing gear, flight controls, and engine accessories, due to their high strength and reliability.

4. Electrical Appliances These bearings are used in various electrical appliances, such as washing machines, refrigerators, and air conditioners, to ensure smooth and quiet operation.

In conclusion, deep groove ball bearings are a versatile and reliable solution for precision and efficiency in a wide range of applications. Their unique design and superior performance make them an ideal choice for various industries and mechanical systems.

deep groove ball bearing 6308.

2. Increased Durability Deep groove ball bearings are designed to withstand harsh operating conditions, such as heavy loads, shock loads, and extreme temperatures. This ensures long-lasting performance and reduces maintenance requirements.

3. Reduced Noise and Vibration The smooth operation of deep groove ball bearings results in reduced noise and vibration in machinery and equipment. This enhances the overall performance and user experience.

Applications of Deep Groove Ball Bearings

1. Industrial Machinery Deep groove ball bearings are commonly used in industrial machinery, such as pumps, fans, compressors, and conveyors, to ensure efficient and reliable operation.

2. Automotive Industry These bearings are widely used in automotive applications, including engines, transmissions, and suspension systems, to improve performance and reduce wear.

3. Aerospace Industry Deep groove ball bearings are essential components in aerospace systems, such as landing gear, flight controls, and engine accessories, due to their high strength and reliability.

4. Electrical Appliances These bearings are used in various electrical appliances, such as washing machines, refrigerators, and air conditioners, to ensure smooth and quiet operation.

In conclusion, deep groove ball bearings are a versatile and reliable solution for precision and efficiency in a wide range of applications. Their unique design and superior performance make them an ideal choice for various industries and mechanical systems. Latest news

-

UCT205-15 Take Up Housing Pillow Block Bearing | Reliable

NewsAug.17,2025

-

CKZ-A Sprag Type Freewheels One Way Clutch - High Performance & Reliable

NewsAug.16,2025

-

ASNU 12-35 NFS TFS Roller Freewheel One Way Clutch Bearings

NewsAug.15,2025

-

Durable AK208 Pillow Block Housing | Reliable Bearing Support

NewsAug.14,2025

-

28.6x80x36.53mm W208PPB5 Heavy Duty Disc Harrow Bearing

NewsAug.13,2025

-

CKZF-B Series Flywheel Backstop Clutch: Reliable Reverse Prevention

NewsAug.12,2025