Jun . 14, 2024 16:52 Back to list

Customized spherical bearing solution

The Custom Sphere Bearing A Precision Engineering Marvel

In the realm of engineering, there lies a unique component that has revolutionized the way machines operate and systems function - the custom sphere bearing. This specialized bearing type is a testament to the power of customization in enhancing performance and efficiency in various industrial applications.

A sphere bearing, also known as a ball bearing, is a fundamental element in mechanical design, primarily used to reduce friction between moving parts. It consists of rolling balls that separate the inner and outer races, allowing smooth and controlled motion. When we talk about a 'custom' sphere bearing, we delve into the world of tailored solutions that cater to specific requirements and operating conditions.

Custom sphere bearings offer an array of benefits over standard models. They are designed with precision to accommodate unique loads, speeds, and environmental factors, ensuring optimal performance in niche applications. Engineers can specify factors such as material composition, size, load capacity, lubrication, and corrosion resistance, creating a bearing that is not only efficient but also durable.

For instance, in high-speed applications like aerospace or automotive industries, custom sphere bearings might incorporate lightweight materials with high strength-to-weight ratios, minimizing rotational inertia. In heavy-duty machinery, they could be engineered to withstand massive loads, using robust materials and advanced coating technologies to enhance wear resistance In heavy-duty machinery, they could be engineered to withstand massive loads, using robust materials and advanced coating technologies to enhance wear resistance In heavy-duty machinery, they could be engineered to withstand massive loads, using robust materials and advanced coating technologies to enhance wear resistance In heavy-duty machinery, they could be engineered to withstand massive loads, using robust materials and advanced coating technologies to enhance wear resistance

In heavy-duty machinery, they could be engineered to withstand massive loads, using robust materials and advanced coating technologies to enhance wear resistance In heavy-duty machinery, they could be engineered to withstand massive loads, using robust materials and advanced coating technologies to enhance wear resistance custom sphere bearing.

Moreover, in environments where cleanliness is critical, like in medical equipment or food processing plants, custom sphere bearings can be manufactured with specialized seals to prevent contamination. They can also be tailored for low noise and vibration in sensitive applications, such as in audio equipment or robotics.

The process of designing a custom sphere bearing involves close collaboration between engineers and manufacturers. Detailed analysis of the application's demands, along with thorough understanding of the operational environment, guides the design phase. Computer-aided design (CAD) tools and finite element analysis (FEA) help predict the bearing's behavior under different conditions, ensuring it meets or exceeds performance expectations.

In conclusion, the custom sphere bearing is more than just a mechanical component; it is a bespoke solution that pushes the boundaries of engineering. It embodies the principles of customization, precision, and innovation, enabling businesses across diverse sectors to achieve higher efficiency, reliability, and longevity in their operations. As technology continues to evolve, so will the capabilities of these bearings, further solidifying their importance in modern engineering.

custom sphere bearing.

Moreover, in environments where cleanliness is critical, like in medical equipment or food processing plants, custom sphere bearings can be manufactured with specialized seals to prevent contamination. They can also be tailored for low noise and vibration in sensitive applications, such as in audio equipment or robotics.

The process of designing a custom sphere bearing involves close collaboration between engineers and manufacturers. Detailed analysis of the application's demands, along with thorough understanding of the operational environment, guides the design phase. Computer-aided design (CAD) tools and finite element analysis (FEA) help predict the bearing's behavior under different conditions, ensuring it meets or exceeds performance expectations.

In conclusion, the custom sphere bearing is more than just a mechanical component; it is a bespoke solution that pushes the boundaries of engineering. It embodies the principles of customization, precision, and innovation, enabling businesses across diverse sectors to achieve higher efficiency, reliability, and longevity in their operations. As technology continues to evolve, so will the capabilities of these bearings, further solidifying their importance in modern engineering.

In heavy-duty machinery, they could be engineered to withstand massive loads, using robust materials and advanced coating technologies to enhance wear resistance In heavy-duty machinery, they could be engineered to withstand massive loads, using robust materials and advanced coating technologies to enhance wear resistance

In heavy-duty machinery, they could be engineered to withstand massive loads, using robust materials and advanced coating technologies to enhance wear resistance In heavy-duty machinery, they could be engineered to withstand massive loads, using robust materials and advanced coating technologies to enhance wear resistance custom sphere bearing.

Moreover, in environments where cleanliness is critical, like in medical equipment or food processing plants, custom sphere bearings can be manufactured with specialized seals to prevent contamination. They can also be tailored for low noise and vibration in sensitive applications, such as in audio equipment or robotics.

The process of designing a custom sphere bearing involves close collaboration between engineers and manufacturers. Detailed analysis of the application's demands, along with thorough understanding of the operational environment, guides the design phase. Computer-aided design (CAD) tools and finite element analysis (FEA) help predict the bearing's behavior under different conditions, ensuring it meets or exceeds performance expectations.

In conclusion, the custom sphere bearing is more than just a mechanical component; it is a bespoke solution that pushes the boundaries of engineering. It embodies the principles of customization, precision, and innovation, enabling businesses across diverse sectors to achieve higher efficiency, reliability, and longevity in their operations. As technology continues to evolve, so will the capabilities of these bearings, further solidifying their importance in modern engineering.

custom sphere bearing.

Moreover, in environments where cleanliness is critical, like in medical equipment or food processing plants, custom sphere bearings can be manufactured with specialized seals to prevent contamination. They can also be tailored for low noise and vibration in sensitive applications, such as in audio equipment or robotics.

The process of designing a custom sphere bearing involves close collaboration between engineers and manufacturers. Detailed analysis of the application's demands, along with thorough understanding of the operational environment, guides the design phase. Computer-aided design (CAD) tools and finite element analysis (FEA) help predict the bearing's behavior under different conditions, ensuring it meets or exceeds performance expectations.

In conclusion, the custom sphere bearing is more than just a mechanical component; it is a bespoke solution that pushes the boundaries of engineering. It embodies the principles of customization, precision, and innovation, enabling businesses across diverse sectors to achieve higher efficiency, reliability, and longevity in their operations. As technology continues to evolve, so will the capabilities of these bearings, further solidifying their importance in modern engineering. Latest news

-

25MM 2 BOLT UCFLX05-14 Flange bearing unit( oval)

NewsMar.07,2025

-

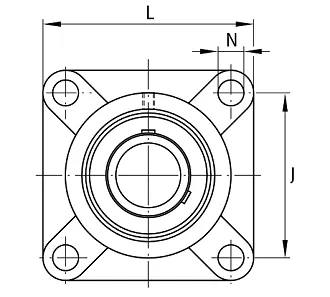

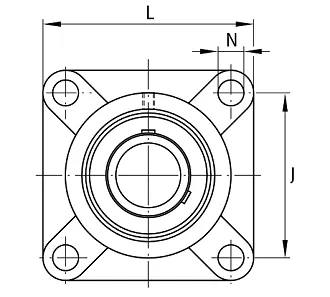

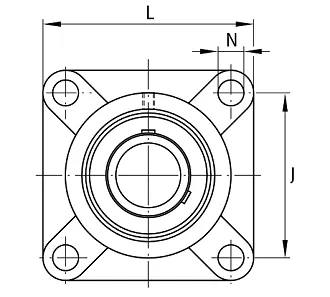

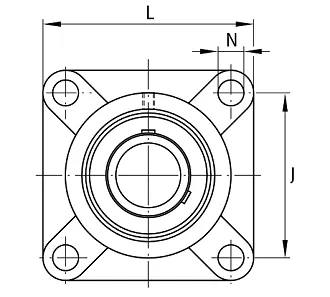

4 bolt UCF 200 series Pillow block bearings

NewsMar.07,2025

-

25MM 2 BOLT UCFLX05-14 Flange bearing unit( oval)

NewsMar.07,2025

-

UCF216-50 4-Bolt Flange Housing Square Bearing

NewsMar.07,2025

-

25MM 2 BOLT UCFLX05-14 Flange bearing unit( oval)

NewsMar.07,2025

-

spherical roller bearing material exporter

NewsMar.07,2025