Jun . 14, 2024 06:36 Back to list

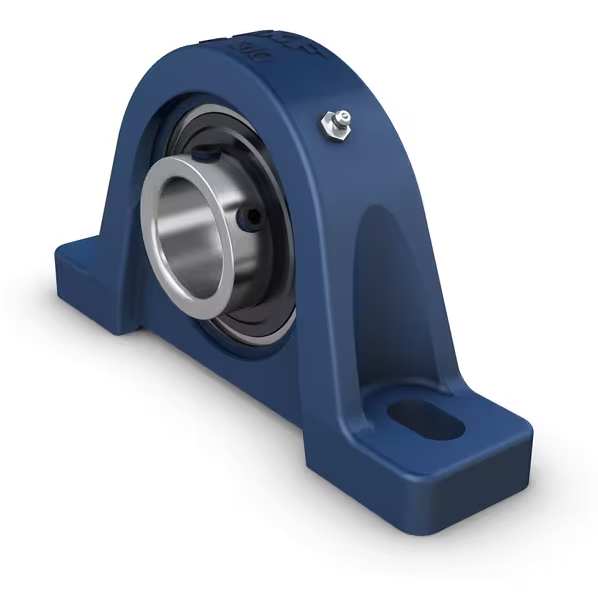

Custom spherical bearing replacement solution.

The Art of Custom Spherical Bearing Replacement

In the intricate world of mechanical systems, custom spherical bearings play a crucial role in ensuring smooth and efficient operation. Over time, however, these bearings may require replacement due to wear and tear or damage, necessitating a meticulous process that balances precision with practicality. This article delves into the nuanced art of replacing custom spherical bearings, providing insights for both novices and seasoned professionals alike.

The initial step involves a thorough assessment of the existing bearing's condition. Signs such as excessive noise, vibration, or decreased performance often indicate the need for replacement. Before proceeding, it is essential to understand the specific application requirements, including load capacities, operating speeds, and environmental conditions, to select a suitable replacement bearing.

Choosing the right bearing is paramount. Custom spherical bearings come in various sizes, materials, and designs, each tailored for different operational needs. Consultation with manufacturers or experts can help match the original bearing's specifications or recommend upgrades that enhance performance and longevity. It is also critical to ensure that the new bearing complies with industry standards and regulations relevant to its application.

Once the replacement bearing is acquired, preparing the work environment becomes the next focus area. Adequate space, cleanliness, and safety measures are prerequisites for a successful installation. Dismantling the assembly containing the old bearing requires careful handling to prevent damage to surrounding components Dismantling the assembly containing the old bearing requires careful handling to prevent damage to surrounding components Dismantling the assembly containing the old bearing requires careful handling to prevent damage to surrounding components Dismantling the assembly containing the old bearing requires careful handling to prevent damage to surrounding components

Dismantling the assembly containing the old bearing requires careful handling to prevent damage to surrounding components Dismantling the assembly containing the old bearing requires careful handling to prevent damage to surrounding components custom spherical bearing replacement. Lubrication should be considered at this stage, as it ensures the new bearing operates under optimal conditions from the outset.

The actual replacement process demands skill and patience. Aligning the new bearing accurately within the assembly is crucial; any misalignment can lead to premature failure. Specialized tools designed for bearing installation ease this task, reducing human error and ensuring correct placement. Torque wrenches and alignment instruments are indispensable for achieving precise fits.

After installation, a series of tests should be conducted to verify proper functioning. These include rotational tests to check for smooth movement and vibration analysis to ensure stability. It is also advisable to monitor the performance of the new bearing over its initial operation cycles to detect any anomalies early on.

In conclusion, replacing a custom spherical bearing is more than just a straightforward swap; it is an exercise in attention to detail, precision engineering, and anticipatory maintenance. By following best practices and employing the right tools and techniques, one can extend the lifespan of critical machinery and maintain operational efficiency. The success of a bearing replacement hinges on a blend of technical know-how and a commitment to excellence in execution.

custom spherical bearing replacement. Lubrication should be considered at this stage, as it ensures the new bearing operates under optimal conditions from the outset.

The actual replacement process demands skill and patience. Aligning the new bearing accurately within the assembly is crucial; any misalignment can lead to premature failure. Specialized tools designed for bearing installation ease this task, reducing human error and ensuring correct placement. Torque wrenches and alignment instruments are indispensable for achieving precise fits.

After installation, a series of tests should be conducted to verify proper functioning. These include rotational tests to check for smooth movement and vibration analysis to ensure stability. It is also advisable to monitor the performance of the new bearing over its initial operation cycles to detect any anomalies early on.

In conclusion, replacing a custom spherical bearing is more than just a straightforward swap; it is an exercise in attention to detail, precision engineering, and anticipatory maintenance. By following best practices and employing the right tools and techniques, one can extend the lifespan of critical machinery and maintain operational efficiency. The success of a bearing replacement hinges on a blend of technical know-how and a commitment to excellence in execution.

Dismantling the assembly containing the old bearing requires careful handling to prevent damage to surrounding components Dismantling the assembly containing the old bearing requires careful handling to prevent damage to surrounding components

Dismantling the assembly containing the old bearing requires careful handling to prevent damage to surrounding components Dismantling the assembly containing the old bearing requires careful handling to prevent damage to surrounding components custom spherical bearing replacement. Lubrication should be considered at this stage, as it ensures the new bearing operates under optimal conditions from the outset.

The actual replacement process demands skill and patience. Aligning the new bearing accurately within the assembly is crucial; any misalignment can lead to premature failure. Specialized tools designed for bearing installation ease this task, reducing human error and ensuring correct placement. Torque wrenches and alignment instruments are indispensable for achieving precise fits.

After installation, a series of tests should be conducted to verify proper functioning. These include rotational tests to check for smooth movement and vibration analysis to ensure stability. It is also advisable to monitor the performance of the new bearing over its initial operation cycles to detect any anomalies early on.

In conclusion, replacing a custom spherical bearing is more than just a straightforward swap; it is an exercise in attention to detail, precision engineering, and anticipatory maintenance. By following best practices and employing the right tools and techniques, one can extend the lifespan of critical machinery and maintain operational efficiency. The success of a bearing replacement hinges on a blend of technical know-how and a commitment to excellence in execution.

custom spherical bearing replacement. Lubrication should be considered at this stage, as it ensures the new bearing operates under optimal conditions from the outset.

The actual replacement process demands skill and patience. Aligning the new bearing accurately within the assembly is crucial; any misalignment can lead to premature failure. Specialized tools designed for bearing installation ease this task, reducing human error and ensuring correct placement. Torque wrenches and alignment instruments are indispensable for achieving precise fits.

After installation, a series of tests should be conducted to verify proper functioning. These include rotational tests to check for smooth movement and vibration analysis to ensure stability. It is also advisable to monitor the performance of the new bearing over its initial operation cycles to detect any anomalies early on.

In conclusion, replacing a custom spherical bearing is more than just a straightforward swap; it is an exercise in attention to detail, precision engineering, and anticipatory maintenance. By following best practices and employing the right tools and techniques, one can extend the lifespan of critical machinery and maintain operational efficiency. The success of a bearing replacement hinges on a blend of technical know-how and a commitment to excellence in execution. Latest news

-

Durable PLC 110-190 Spherical Roller Bearing for Mixer Reducer

NewsAug.26,2025

-

CSK-2RS Sprag Clutch One Way Bearing: Sealed, High Torque, Durable

NewsAug.25,2025

-

CKZ-D Series One Way Overrunning Clutch: Reliable Power Control

NewsAug.24,2025

-

203KRR3 Round Bore Series Bearings | Cylindrical Outer Ring, Precision

NewsAug.23,2025

-

Top Spherical Roller Bearing Material Exporter - High Performance

NewsAug.22,2025

-

Durable UCFC202-09 Round Flange Housing 4-Bolt Ball Bearing

NewsAug.21,2025