Jun . 16, 2024 19:23 Back to list

Custom bucket elevator bearings.

The Custom Bucket Elevator Bearings An Innovation in Material Handling

In the world of industrial material handling, the efficiency and durability of equipment are paramount. One such piece of equipment that has seen a significant advancement is the bucket elevator, thanks to the introduction of custom bucket elevator bearings. These specialized bearings have revolutionized the way materials are transported, reducing maintenance requirements and increasing operational longevity.

Bucket elevators are vertical transportation systems used extensively in industries ranging from grain processing to recycling facilities. They consist of a series of buckets attached to a continuous loop chain that moves materials from the ground level to a higher elevation. The bearings in these systems play a crucial role, as they support the movement of the chain and bucket assembly, ensuring smooth operation and minimizing friction.

Traditionally, standard bearings were employed in these applications, but they often struggled to cope with the heavy loads, dust, and variable temperatures found in industrial environments. This led to frequent failures and costly downtime for maintenance and replacements. Recognizing this issue, manufacturers began developing custom bucket elevator bearings designed specifically for these harsh conditions.

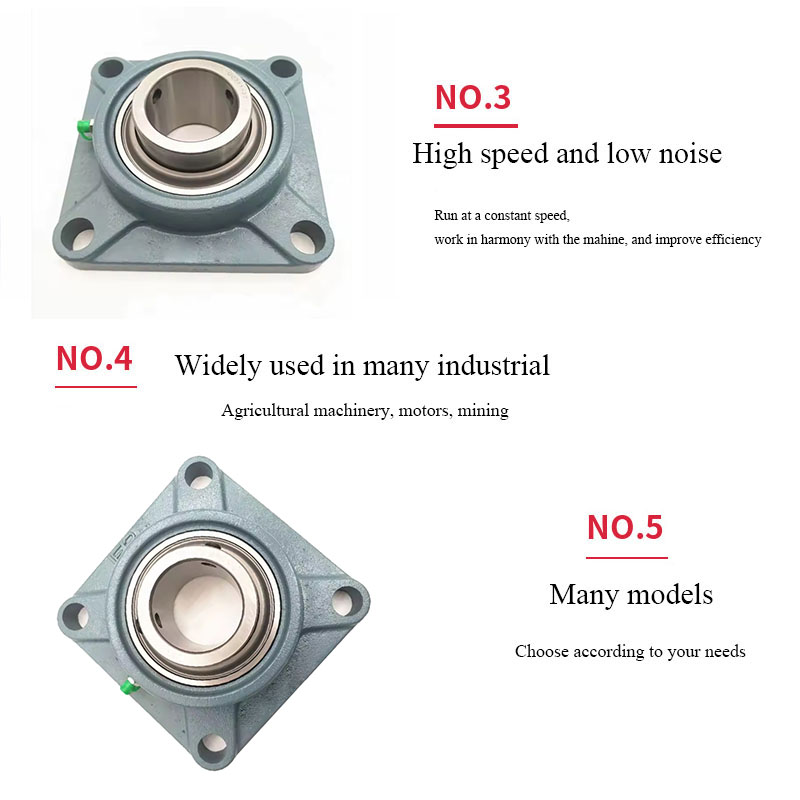

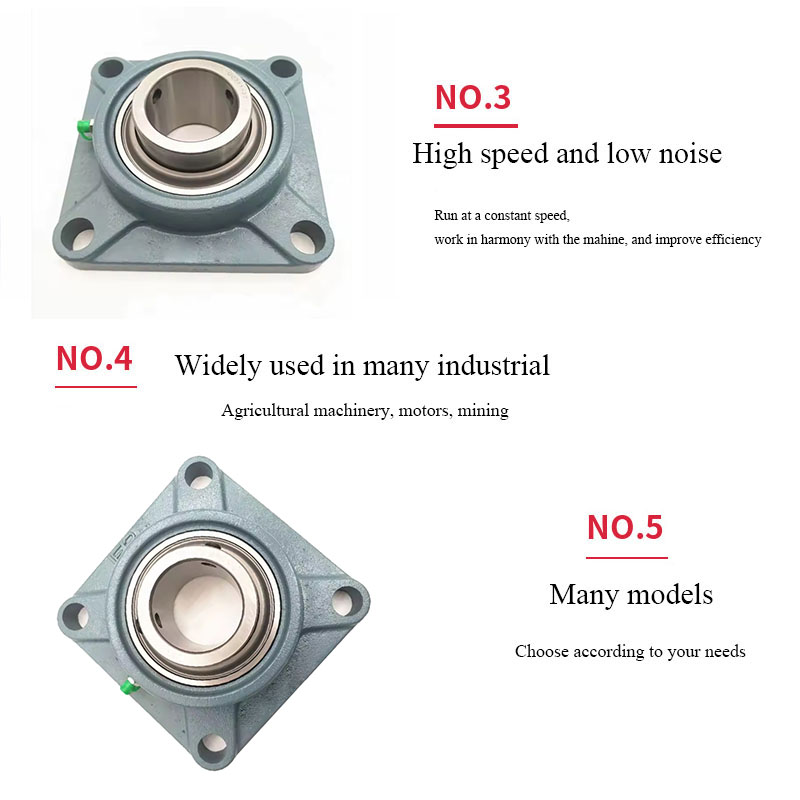

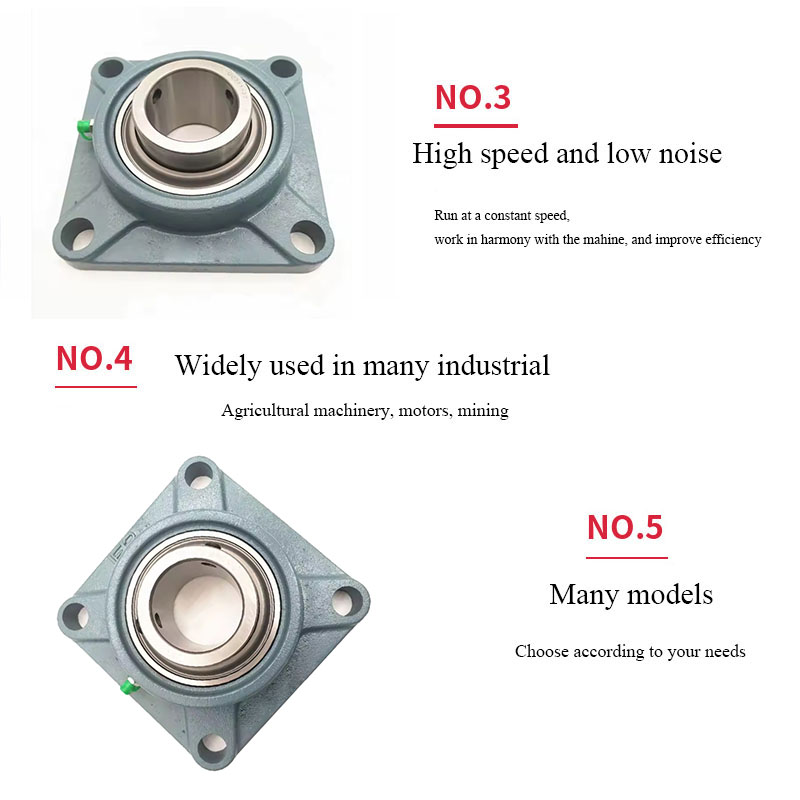

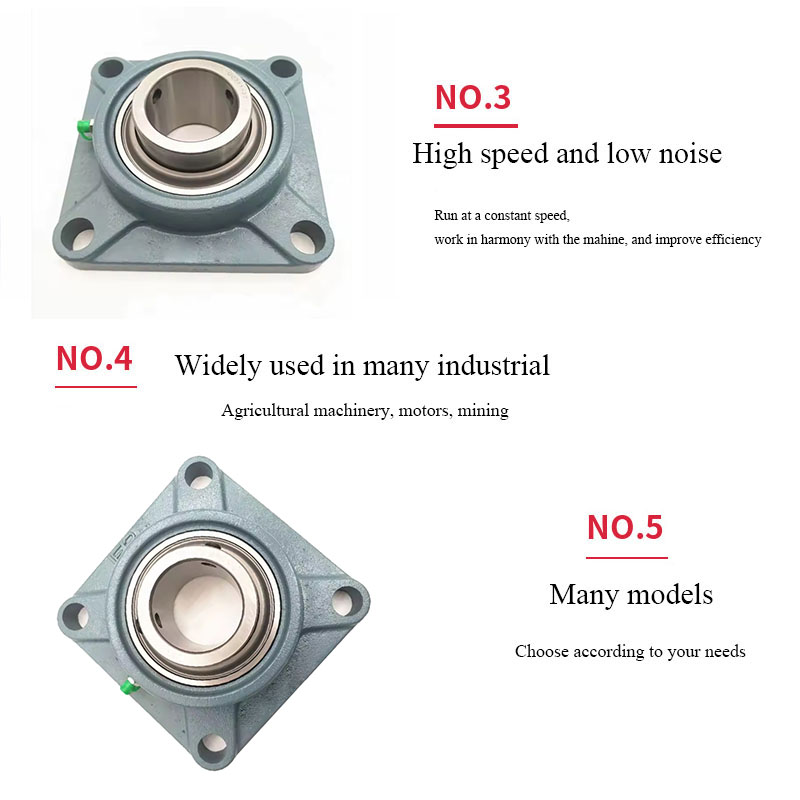

These custom bearings are made from high-quality materials that resist corrosion and wear, ensuring they can withstand the demands of industrial use. They are also often sealed to prevent dust and other contaminants from entering, which significantly improves their lifespan and reduces the need for lubrication They are also often sealed to prevent dust and other contaminants from entering, which significantly improves their lifespan and reduces the need for lubrication They are also often sealed to prevent dust and other contaminants from entering, which significantly improves their lifespan and reduces the need for lubrication They are also often sealed to prevent dust and other contaminants from entering, which significantly improves their lifespan and reduces the need for lubrication

They are also often sealed to prevent dust and other contaminants from entering, which significantly improves their lifespan and reduces the need for lubrication They are also often sealed to prevent dust and other contaminants from entering, which significantly improves their lifespan and reduces the need for lubrication custom bucket elevator bearings. Furthermore, the design of these bearings often includes features such as increased load capacities and enhanced shock absorption, making them ideal for applications where heavy materials are being transported.

The benefits of using custom bucket elevator bearings are multifaceted. Firstly, they reduce operational costs by extending the time between maintenance cycles. Secondly, they provide a more reliable transportation method, which is critical in production lines where downtime can be extremely costly. Additionally, these bearings contribute to safer working environments by reducing the risk of equipment failure that could potentially harm workers or damage products.

In conclusion, the advent of custom bucket elevator bearings represents a significant step forward in industrial material handling. By addressing the specific challenges faced by these systems, manufacturers have created a product that not only enhances efficiency but also provides a cost-effective and safe solution for transporting materials in various industries. As technology continues to advance, it is likely that we will see further innovations in this field, pushing the boundaries of what is possible in material handling.

custom bucket elevator bearings. Furthermore, the design of these bearings often includes features such as increased load capacities and enhanced shock absorption, making them ideal for applications where heavy materials are being transported.

The benefits of using custom bucket elevator bearings are multifaceted. Firstly, they reduce operational costs by extending the time between maintenance cycles. Secondly, they provide a more reliable transportation method, which is critical in production lines where downtime can be extremely costly. Additionally, these bearings contribute to safer working environments by reducing the risk of equipment failure that could potentially harm workers or damage products.

In conclusion, the advent of custom bucket elevator bearings represents a significant step forward in industrial material handling. By addressing the specific challenges faced by these systems, manufacturers have created a product that not only enhances efficiency but also provides a cost-effective and safe solution for transporting materials in various industries. As technology continues to advance, it is likely that we will see further innovations in this field, pushing the boundaries of what is possible in material handling.

They are also often sealed to prevent dust and other contaminants from entering, which significantly improves their lifespan and reduces the need for lubrication They are also often sealed to prevent dust and other contaminants from entering, which significantly improves their lifespan and reduces the need for lubrication

They are also often sealed to prevent dust and other contaminants from entering, which significantly improves their lifespan and reduces the need for lubrication They are also often sealed to prevent dust and other contaminants from entering, which significantly improves their lifespan and reduces the need for lubrication custom bucket elevator bearings. Furthermore, the design of these bearings often includes features such as increased load capacities and enhanced shock absorption, making them ideal for applications where heavy materials are being transported.

The benefits of using custom bucket elevator bearings are multifaceted. Firstly, they reduce operational costs by extending the time between maintenance cycles. Secondly, they provide a more reliable transportation method, which is critical in production lines where downtime can be extremely costly. Additionally, these bearings contribute to safer working environments by reducing the risk of equipment failure that could potentially harm workers or damage products.

In conclusion, the advent of custom bucket elevator bearings represents a significant step forward in industrial material handling. By addressing the specific challenges faced by these systems, manufacturers have created a product that not only enhances efficiency but also provides a cost-effective and safe solution for transporting materials in various industries. As technology continues to advance, it is likely that we will see further innovations in this field, pushing the boundaries of what is possible in material handling.

custom bucket elevator bearings. Furthermore, the design of these bearings often includes features such as increased load capacities and enhanced shock absorption, making them ideal for applications where heavy materials are being transported.

The benefits of using custom bucket elevator bearings are multifaceted. Firstly, they reduce operational costs by extending the time between maintenance cycles. Secondly, they provide a more reliable transportation method, which is critical in production lines where downtime can be extremely costly. Additionally, these bearings contribute to safer working environments by reducing the risk of equipment failure that could potentially harm workers or damage products.

In conclusion, the advent of custom bucket elevator bearings represents a significant step forward in industrial material handling. By addressing the specific challenges faced by these systems, manufacturers have created a product that not only enhances efficiency but also provides a cost-effective and safe solution for transporting materials in various industries. As technology continues to advance, it is likely that we will see further innovations in this field, pushing the boundaries of what is possible in material handling. Latest news

-

203KRR3 Round Bore Series Bearings | Cylindrical Outer Ring, Precision

NewsAug.23,2025

-

Top Spherical Roller Bearing Material Exporter - High Performance

NewsAug.22,2025

-

Durable UCFC202-09 Round Flange Housing 4-Bolt Ball Bearing

NewsAug.21,2025

-

25x52x44.4mm UEL205 Bearing with Eccentric Sleeve

NewsAug.19,2025

-

High Quality 6319 2RS Deep Groove Ball Bearing 95x200x45

NewsAug.18,2025

-

UCT205-15 Take Up Housing Pillow Block Bearing | Reliable

NewsAug.17,2025