Apr . 24, 2024 11:08 Back to list

Classification of bearings

Bearings can be classified based on different criteria, such as design and operating mode, allowed motion or direction of load. From a design perspective, bearings can be classified into:

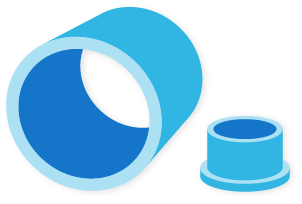

Plain bearings – Also referred to as bushes, bushings or sleeve bearings, these are the simplest type of bearings. With a cylindrical shape and no moving parts, they are usually used in machines with a rotating or sliding shaft component. Plain bearings can be made of metal or plastic and can use a lubricant like oil or graphite for reducing the friction between the shaft and the hole it rotates in. Typically, they are used for sliding, rotation, oscillating or reciprocating motion.

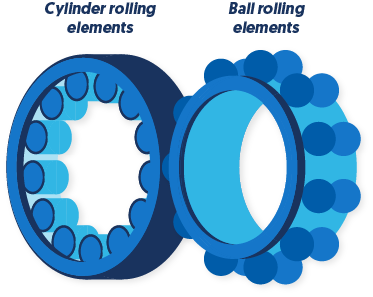

Rolling-element bearings - These bearings have a more complex design and are used for supporting higher loads. They consist of rolling elements such as balls or cylinders which are placed between a turning and a stationary race. The relative motion of the races causes the movement of the rolling elements, with little friction and little sliding.

Depending on the shape of the rolling elements, these bearings can be further classified into ball bearings and roller bearings, with various sub-types: cylindrical roller bearings, spherical roller bearings, tapered roller bearings, needle roller bearings and gear bearings.

Fluid bearings - As their name suggests, these bearings contain a layer of fluid between the bearing surfaces. The fluid can be either a pressurized liquid or a gas, and is distributed in a thin layer which moves rapidly between the internal and external races. Since the bearing surfaces have no direct contact, there is no sliding friction in this type of bearings, therefore the overall friction and wear of these components is much lower than in rolling-element bearings.

Magnetic bearings - These bearings make use of magnetic levitation for supporting the loads, which means there is no surface contact within the bearing. By eliminating friction and the wear of materials, magnetic bearings have a much longer life and can support the highest speeds of all types of bearings. These components are often preferred in industrial applications like petroleum refinement, natural gas handling or electrical power generation, but also in optical systems with high rotational speeds and in vacuum applications.

We’ll discuss the most common types of bearings more in detail in the next chapters of this guide, but right now we’ll continue with the classification of bearings.

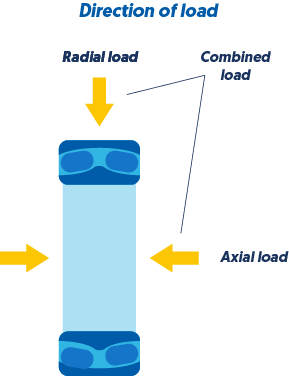

Another criterion for categorizing bearings is the direction of the load they can accommodate. From this point of view, bearings are grouped into three main categories: radial bearings, thrust bearings and linear bearings.

The contact angle between the bearing and the shaft determines the type of bearing: radial bearings have a contact angle under 45°, while thrust bearings have a contact angle above 45°.

Linear bearings guide the moving parts in a straight line. They are also referred to as linear guides and come in two main shapes: round and square.

Radial bearings can support loads that fall perpendicularly to the shaft. Depending on the design, they may also accommodate some axial loads, in one or two directions. Radial bearings are installed perpendicularly to the axial line of the shaft. Plain bearings - also called journal bearings - are often used as radial bearings.

Thrust bearings support loads that are parallel to the bearing axis, so they are designed to withstand forces in the same direction as the shaft (axial loads).

Depending on their design, these bearings can handle pure axial loads in one or two directions, and sometimes also some radial loads, but unlike radial bearings, these components cannot accommodate very high speeds.

NOTE: Given that both plain and rolling-element bearings can transmit loads in radial and axial directions, the choice of bearing design depends on the application requirements.

![]() Wide assortment of bearings and accessories

Wide assortment of bearings and accessories

In our webshop you will find a wide variety of bearings, along with housings and lubricants. Explore our full assortment of bearings from top brands like SKF, FAG, INA, NSK and TIMKEN, and find the right product for your application.

2. Plain bearings design and applications

As previously said, there are two main types of bearing constructions: plain bearings and rolling-element bearings. Let's see which are the most common sub-types for each of these categories, and what are the differences between them in terms of design, materials and applications.

Plain bearings are made of a single bearing surface, with no rolling parts. The design depends on the type of motion required, and on the load that the bearing has to withstand. These machine components are quieter in operation than rolling-element bearings, have a lower cost and require less space.

On the other hand, they have a higher friction between the surfaces, which can lead to a higher power consumption in the machine, and are more susceptible to damage if impurities get into the lubricant.

Plain bearings can be made from different materials, but they have to be durable, low wear and low friction, resistant to temperatures and corrosion. Often, the bearing surfaces are made of at least two components of which one is softer and one is harder. Common materials include babbitt, a bi-material that consists of a metal shell and a plastic bearing surface, cast iron, bronze, graphite, as well as ceramics and plastics.

Although plain bearings often require lubrication, they are - at least theoretically - capable of running indefinitely, so they can be used in applications where the failure of these components would lead to severe consequences. For example, large industrial turbines like power plant steam turbines, compressors operating in critical applications, automotive engines, marine applications and so on.

In what concerns the main types of plain bearings, from a structural point of view there are three important categories: sleeves or bushings, integral bearings and two-piece plain bearings. Another classification of plain bearings categorizes them into hydrodynamic and hydrostatic bearings.

Spherical plain bearings

Spherical plain bearings have an inner ring with a convex outside surface and an outer ring with a concave inside surface. The two rings are mounted together, so there are no rolling elements in between. However, depending on the materials used for the rings, a layer of coating can be applied for reducing the wear.

Bearings in which both rings are made of steel require maintenance, as they have hardened sliding contact surfaces on both rings. These are coated with materials like molybdenum disulphide, hard chromium or phosphate, which increase the wear and corrosion resistance. To facilitate relubrication, these bearings feature lubrication holes and an annular groove.

Spherical plain bearings that require maintenance (steel-on-steel) are suitable for applications where heavy loads of alternating direction, heavy static loads or shock loads are involved.

Maintenance-free spherical plain bearings are intended for application where a long and maintenance-free bearing life is needed, for example in machines and assemblies where relubrication would be difficult. These bearings are usually made of materials like steel and PTFE composite, PTFE fabric or copper alloy. The ability to withstand dynamic loads is higher than in steel-on-steel bearings, and thanks to the used materials, these bearings have lower friction.

Depending on the materials, the outer ring can be pressed around the inner ring or can have or can have radial splits which are held together by screws. The contact surfaces can be coated with chromium, PTFE or phosphate, to increase wear and corrosion resistance. In some designs, seals can be added to reduce contamination and extend the bearing life.

Spherical plain bearings are suitable for applications where alignment movements between the shaft and housing have to be accommodated. When they can withstand heavy loads and shocks, they are also referred to as heavy-duty spherical plain bearings.

Rod ends

Rod end bearings, also referred to as Rose joints or Heim joints, consist of an eye-shaped head with integral shank, which is used as housing for a spherical plain bearing. The internal thread is usually left- or ring-hand female, while the external thread is male.

The bearing is fixed inside the housing, so unlike spherical plain bearings, which offer misalignment capabilities, rod ends don't have this characteristic. They are, however, very easy to mount, provide a compact and lightweight design and are a good alternative to a conventional housing element. Rod end bearings are often used in control rods, mechanisms and linkages, being easy to integrate in various applications.

Just like spherical plain bearings, rod ends can be maintenance-free or can require maintenance. Steel-on-steel and steel-on-bronze rod ends have good wear-resistant sliding surfaces, but require regular lubrication. They are suitable for applications where heavy alternating loads are involved.

In what concerns maintenance-free rod end bearings, these are usually made of materials like steel and PTFE composite or steel and PTFE fabric, in this case the friction forces being much lower. These bearings are suitable for applications where a long bearing life is required, where relubrication would be difficult and where the loads have a constant direction.

Bushings

The most common type of plain bearing is the bushing or bush, which is an independent element inserted into a housing to provide a supporting surface. The shape is usually cylindrical, the standard configurations being the sleeve bearing and the flanged bearing. Sleeve bearings have straight inside and outside surfaces and equal diameters, while the flanged ones have a flange at one end that is used for locating the element in an assembly, and sometimes also for covering the mounting holes and securing the bearing in place.

Additionally, plain bearings can be lined, in this case a different material being used for the inside and outside surfaces. Bushings are used for linear, oscillating and rotating movements, the straight sleeves being suitable for radial loads, while the flanged bushings are able to withstand radial and axial loads in one direction.

Unlike rolling-element bearings, plain bearings – including bushings – function via a sliding action. Their construction can be single- or multi-layered, depending on the needed strength. Plain bearings are made from a variety of materials, and are often self-lubricating, this particularity ensuring a smoother operation and greater durability.

The most common materials used for bushings are cast and machined metals, ceramics, fiber-wound composites, stabilized polymer materials and combinations of these. As for lubricants, both solid and fluid ones can be used, but the solid lubricants can usually operate at higher temperatures than oil- or grease-based ones. For some applications, bushings run dry, with no additional lubrication.

The construction of bushings can be solid or with a split or clench. The difference between the solid and the split bushing (wrapped bearing) is that the latter features a cut along its length, for easier installation. The clenched bearing is similar to the split one, but has a clench across the cut connecting the parts.

In general, linear bushings are not pressed into a housing, but secured with retaining rings or with rings that are molded into the outer diameter of the bushing. When bushings are used similarly to washers, they are called thrust washers. However, there is a difference between them: unlike standard spacers or washers, thrust washers must carry a load and shouldn’t wear out over time.

Self-lubricating bushings

A particular type of bushing is the self-lubricating one, in which a solid lubricating film is created inside the bearing through transfer of a small amount of surface material. This happens in the initial run-in period of the bearing, but the amount of material transferred is small enough to not interfere with the functioning and load-handling properties of the bearing.

The film is in contact with all the moving parts of the device, lubricating and protecting them, therefore it helps in extending the service life of the bearing. By doing so it eliminates the need of extra lubrication and reduces the costs with maintenance. Self-lubricating bushings have the advantage of being more lightweight thanks to the thinner walls, and of heaving excellent wear resistance. They can withstand high loads and have a simplified design that makes them more economical in the long run.

Two-piece plain bearings

Also referred to as full bearings, two-piece plain bearings are used in industrial machinery where larger diameters are required, such as crankshaft bearings. They are made of two parts called shells, which are kept in place using different mechanisms.

If the shells are large and thick, a button stop or a dowel pin can be used for locating them. The button stop is screwed on the housing, and the dowel pin links the two shells together. Another possibility is to use a tab on the parting line edge that corelates with a notch in the housing, to prevent the movement of the shells after installation.

Latest news

-

Spherical Bearing Installation

NewsJun.11,2025

-

Sphere Bearing Applications About Key Uses

NewsJun.11,2025

-

Long-Lasting Bearing Options

NewsJun.11,2025

-

Deep Groove Ball Bearing Basics

NewsJun.11,2025

-

Comprehensive Guide to Zirconia Bearing Testing

NewsJun.11,2025

-

Ceramic Bearing Selection Guide

NewsJun.11,2025