Mar . 22, 2024 15:12 Back to list

Ceramic Bearings Vs. Steel Bearings On Bicycles. Which Is Best? Ceramic Bearing

Ceramic bearings are often represented as the ultimate way to minimize rolling friction on your bike. The influx of ceramic bearing development into the bike industry sparked needed focus on reducing rolling friction in bearings. However, the reality of why some bearing designs are faster than others doesn’t always align with what is presented. With this in mind, we’ll dive into what matters most when it comes to the performance of bearings on a bicycle.

Cutting To The Chase On Ceramic Bearings On A Bicycle

On a bicycle, which is considered a “low speed” application (compared to a Formula 1 car or motorcycle engine, for example), the ball bearing material itself (steel or ceramic) has little to no effect on the friction of the bearing assembly. When it comes to rolling friction, what matters far more are the “cheap parts” – the seals and the grease.

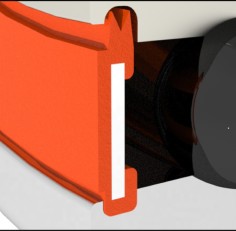

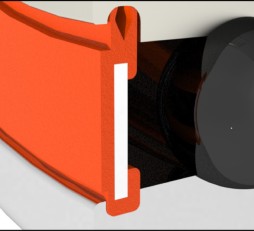

Resistance Zro2 Full Ceramic Self-Aligning Ball BearingT

The bottom line is that the seals and the grease are more important to performance more than whether the bearing is ceramic or steel. How much more important? Read on…

What Is A Ceramic Bearing?

Most ceramic bearings in the bicycle industry consist of ceramic silicon-nitride balls housed between steel races. While “full ceramic bearings” (ceramic races) do exist, they are reserved for low impact areas like derailleur pulleys. Why? Because ceramic races are more brittle than steel; cracking a race could stop a wheel from turning instantly and no good comes of wheels permanently locking up on a bicycle. So, for safety reasons, ceramic wheel bearings on bicycles are in-fact almost always hybrid design – meaning ceramic balls on steel races.

Where Does Friction Originate In A Bearing?

50-60% of bearing friction on a bicycle comes from the seals/shield. The design of the seal plays a huge role in how easily the bearing spins under load, but also in how well it keeps out the elements. There is give and take; think about how to balance performance with durability when upgrading bearings.

25-35% of bearing friction on a bicycle bearing comes from the grease/lubricant the bearings are coated. The type of lubricant and how dense it is packed in the bearings matters a great deal.

10-16% of bearing friction on a bicycle bearing comes from bearing component friction (ball and race deformity) and bearing cage friction. The majority of this friction is from the bearing cage; only 3% of overall friction can be attributed to the ball bearings themselves.

What does this mean? It means that the balls being ceramic are not the reason why one bearing may spin better than another. Within a given tolerance range (Grade) Ball bearing material has little to do with bearing performance.

What To Know About Bicycle Bearing Seals

Non-Contact Seal on an Enduro Bearing

The number one contributor to friction in a bicycle bearing is the seals. This is why it is not unheard of for track riders (riding in a low contaminant environment) to run bearings without any seals at all.

Based on the importance of the seal to friction, what do you need to know about bearing seals?

There are two types of seals. “Non-Contact” and “Fully-Contacted”.

In a non-contact seal there is no contact between the seal and the bearing shell. Instead, there is a thin layer of grease between the seal and the shell. Thus the seal friction and impermeability depends on the viscosity and thickness of the lubricant/grease. Non-contact bearings can be quite fast, but they don’t seal as well as fully-contacted.

As the name says, a full-contact seal is sandwiched between the inner and outer races and the seal actually contacts both. There will generally be a tighter seal on a fully-contacted bearing than a non-contact seal, but the amount of friction depends on a number of design factors.

Full Contact Bearing Seal on an Enduro Bearing

It would be nice if manufacturers focused less on highlighting the grade or material of the bearing in their marketing and brought more clarity to the seal design and its intent. This being said, explaining the nuances of seals is difficult to wrap up in a word or two while saying “Ceramic” or “Grade 3” is not…

Bearing Grease/Lubrication

I’m not going to penetrate the topic of bicycle bearing grease very deeply in this article. However, in terms of selecting appropriate bearings for your needs, it is good to be aware of the following:

- A bearing that is injected with a lot of grease will have more friction than a bearing with a light grease fill.

- Thick grease is more impervious to contamination than thin grease, but can add significant drag.

In summary, bearings with a thin coating of light grease will generally have the lowest friction while bearings with a higher pack of heavier grease will be better protected from the environment.

As mentioned in the discussion of seals, it would be nice if lubricant qualities were easier to communicate in a word or two and if bearing manufacturers communicated what they use better. As with seals, the grease being used has a much greater effect on performance at a given moment than whether a bearing is Grade 3 or Grade 5 or Ceramic or steel.

Bearing Friction

While 10-16% of friction comes from the construction of the actual bearings, races and bearing cages, there isn’t huge opportunity for improvement in these components. Why? There is no way to completely eliminate friction between these components.

Of the different components of a bearing (races, cages, seals, grease…), friction from the actual ball bearings is only about 3%. Frictional differences between a high quality steel ball and a ceramic is a 10-15% improvement at best. This means that the overall friction reduction between a high quality steel bearing and a ceramic is below 0.5%. Put into watts, this means that a high quality steel bearing that starts with 0.4 watts of resistance may have 0.38 watts (all else being equal) if it were high grade ceramic.

Associated, it is interesting to note that between the races, bearings and cages, the majority of the friction is in the bearing cage. The polymer cage retainer design used in most ceramic bearings (and many steel bearings…) has more friction than a steel cage that some better steel bearings use. This difference in materials is enough that it would cancel out the marginal friction difference in the ball materials.

All else being equal, a steel bearing that uses a steel cage will usually have the lowest cage friction. High quality steel bearing assemblies compete extremely well with the very best ceramic bearings in terms of friction.

It is worth stressing that we are literally talking hundredths of a watt difference between the top performing bearings, regardless of material. Good luck seeing that on your power meter.

Maintenance & Wear Differences Between Steel And Ceramic Bearings

How much maintenance a bearing requires depends on the conditions it is used, the load on it, and the seals and grease. Per what we learned in how bearing friction works, the more you reduce seal friction and thin the grease the lower the friction, but the more pervious to contamination it becomes and thus the more service may be required. This is true of both steel and ceramic bearings.

This means that, regardless of bearing material, highly sealed bearings will be less prone to contaminants and/or require less maintenance than low-friction bearings. Otherwise, bearings with the lowest friction will generally require more frequent cleaning and greasing (especially when used in the wet) than higher friction bearings.

In other words, if all else is equal, there is not enough of a maintenance difference between steel and ceramic bearings to matter. Low friction bearings need to be kept drier and serviced more. High friction bearings are slower, but hold up to grit and water better.

So, why do you sometimes hear that ceramic bearings require more service? Because ceramic bearing assemblies in the bike industry are almost always low friction based designs (light seals and grease). Low friction designs are more permeable to the elements and thus require more maintenance.

Studies show that most ceramic bearings gain friction with use at a significantly higher rate than their steel counterparts. This is because the harder ceramic ball wears the softer steel races and rubber cages faster. So, after 500 miles, some ceramic bearing performance will drop off (up to a watt) well below the comparable steel bearing. This means that some used ceramic cartridge bearings actually have more friction than their steel counterparts.

Why Do Ceramic Bearings Exist?

If ceramic bearings do not benefit performance over steel, why do they exist? Ceramic bearings exist to help manage heat in high RPM applications; they don’t expand or deform when they contact each other (Hertzian stress) as much as steel bearings when they get really hot. While a Formula 1 engine revving to 15,000+ RPM can create a lot of heat that can deform and swell steel bearings.

Bikes don’t create this type of heat. The fact of the matter is that the bicycle industry embraced ceramic bearings for marketing reasons as much as anything else; the single word (“ceramic”) sounds faster than “steel” and that counts for a lot.

This being said, all is not lost. The introduction of ceramic bearings to the bike industry played a major role in creating awareness. Improvements in seal design and the application and development of more advanced greases would not have been nearly as likely without the popularity of high performance ceramic designs.

Why Buy Ceramic Bearings For A Bike?

It is worth remembering that a good ceramic bearing is a very good and fast bearing. They do what they claim in terms of performance, but cost more than similar performing steel bearings in many applications. If steel bearings can perform at similar levels for a lower cost, why would you buy a ceramic?

Design. While we see it less than we did a few years ago, sometimes the best bearing seal and grease design for a particular application is only available in a ceramic bearing. Most manufacturers who advertise ceramic bearings realize that people want to buy them to be faster. Thus the design of the bearing uses seals and lubricants that enhance speed. The “ceramic” title is the marketing that they know will get people’s attention, but it is the design of the bearing itself and the quality and maintenance of the assembly that is the vast majority of what actually makes it fast.

Care in Assembly. Many of the better ceramic bearing assemblies are built with far more care than a basic steel bearing assembly. Some are assembled and lubricated by hand and carefully inspected for quality. There is some confidence in what you pay. If you are spending $100+ on a bearing, it is pretty easy to know that you are likely getting a carefully assembled bearing.

It is worth noting that the highest quality steel bearings are built with similar attention to detail as quality ceramics. More expensive bearings usually have better attention to detail and quality and you can almost be guaranteed of this when buying a name brand ceramic bearing. This can be more nuanced with steel bearings. It is sometimes difficult to tell where high quality and basic separate when price points are closer.

Weight. Silicon nitride, which makes up the balls of a ceramic bearing, is about 30% lighter than steel. What does this mean in the “real world”? A BB30 bottom bracket that uses ceramic bearings will weigh 3-5 grams less than its stainless steel counterpart.

While the first two items were more prevalent distinguishers between ceramic and steel bearings in the past, today there are often comparably built steel versions of a given bearing assembly. You may have to dig a little harder to find the high quality steel version though.

Latest news

-

Top Spherical Roller Bearing Material Exporter - High-Performance Alloys

NewsAug.27,2025

-

Durable PLC 110-190 Spherical Roller Bearing for Mixer Reducer

NewsAug.26,2025

-

CSK-2RS Sprag Clutch One Way Bearing: Sealed, High Torque, Durable

NewsAug.25,2025

-

CKZ-D Series One Way Overrunning Clutch: Reliable Power Control

NewsAug.24,2025

-

203KRR3 Round Bore Series Bearings | Cylindrical Outer Ring, Precision

NewsAug.23,2025

-

Top Spherical Roller Bearing Material Exporter - High Performance

NewsAug.22,2025