Feb . 22, 2024 11:22 Back to list

The Heart of Industry

Bearings: The Heart of Industry

In modern mechanical engineering, bearings are indispensable key components that support rotating parts, reduce friction, improve energy efficiency, and ensure the smooth operation of machinery. Bearings come in a wide variety of types, from simple ball bearings to complex precision instrument bearings, playing a crucial role in various industrial applications.

Types of Bearings

Bearings can be classified into several types based on their structure and working principle:

-

Rolling Bearings: Including deep groove ball bearings, tapered roller bearings, cylindrical roller bearings, etc., they support loads through rolling elements (such as balls or rollers) to reduce friction.

-

Sliding Bearings: These bearings use sliding surfaces to support loads and are typically made of metal or plastic, suitable for high-speed or high-temperature environments.

-

Self-Lubricating Bearings: These bearings contain lubricants internally and can operate without external lubrication, making them suitable for environments where lubrication is difficult.

-

Magnetic Bearings: Utilizing magnetic levitation technology, these bearings suspend the rotating shaft without contact, achieving extremely low friction and high precision.

Applications of Bearings

Bearings are widely used in various mechanical and equipment, such as automobiles, aircraft, industrial machinery, and household appliances. In the automotive industry, bearings are used to support engines, transmissions, and wheels; in wind turbines, they ensure the precise positioning and smooth rotation of the blades; in precision instruments like watches and measuring devices, bearings guarantee the accurate movement of mechanical components.

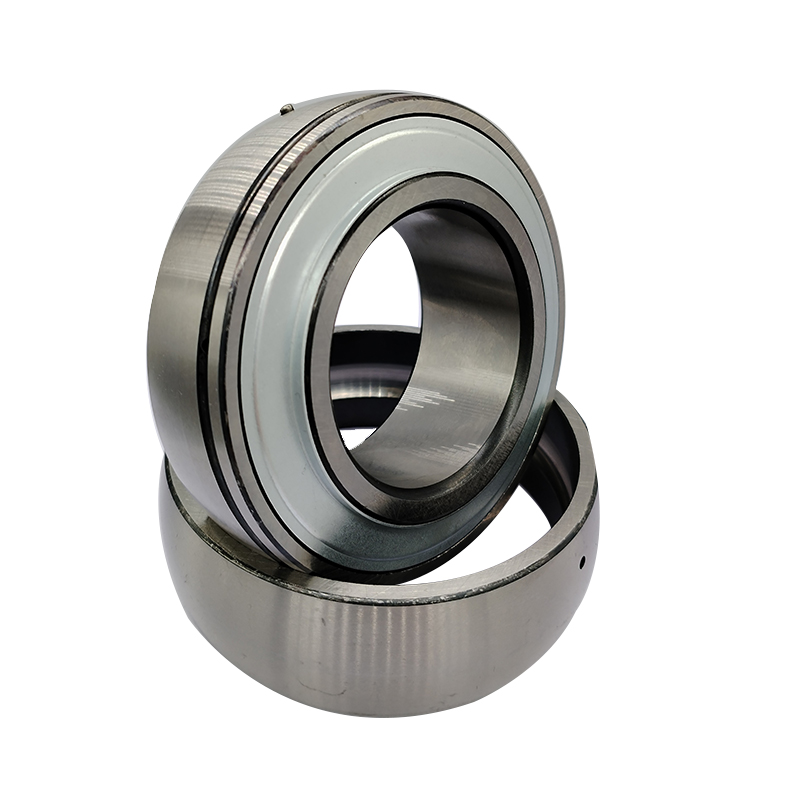

UK205 25*52MM Ball Bearing With Tapered BoreT

The Importance of Maintenance

Although bearings are designed for long-term trouble-free operation, proper maintenance is still crucial. Regularly checking the lubrication status, cleanliness, and wear of bearings can significantly extend their service life. Insufficient lubrication or excessive wear can lead to bearing failure, thereby affecting the reliability and performance of the entire mechanical system.

Conclusion

Bearings are the cornerstone of modern industry, and their performance directly affects the efficiency and lifespan of mechanical equipment. Understanding the types, applications, and maintenance of bearings is essential for ensuring the continuity and reliability of industrial production. With technological advancements, the design and materials of bearings are also constantly innovating to meet more demanding working conditions and higher performance requirements.

Latest news

-

CKZ-A Sprag Type Freewheels One Way Clutch - High Performance & Reliable

NewsAug.16,2025

-

ASNU 12-35 NFS TFS Roller Freewheel One Way Clutch Bearings

NewsAug.15,2025

-

Durable AK208 Pillow Block Housing | Reliable Bearing Support

NewsAug.14,2025

-

28.6x80x36.53mm W208PPB5 Heavy Duty Disc Harrow Bearing

NewsAug.13,2025

-

CKZF-B Series Flywheel Backstop Clutch: Reliable Reverse Prevention

NewsAug.12,2025

-

W210PPB6 PEER Square Bore Farm Bearings - Heavy-Duty & Durable

NewsAug.11,2025