Jun . 26, 2024 08:54 Back to list

Advanced Custom Deep Groove Ball Bearings for Enhanced Industrial Applications

The Unparalleled Performance of Custom Deep Groove Ball Bearings A Revolutionary Technology for Optimal Efficiency

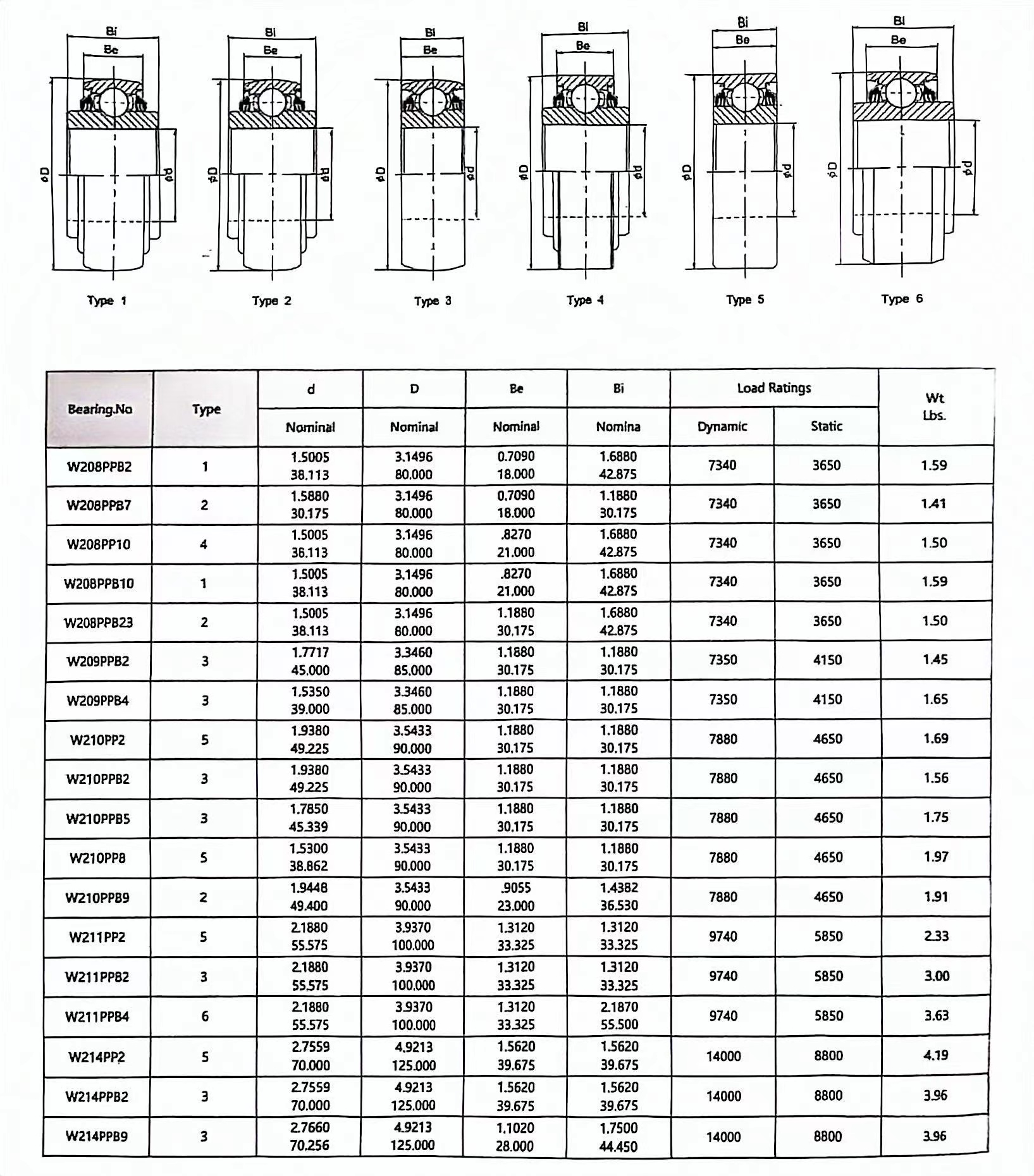

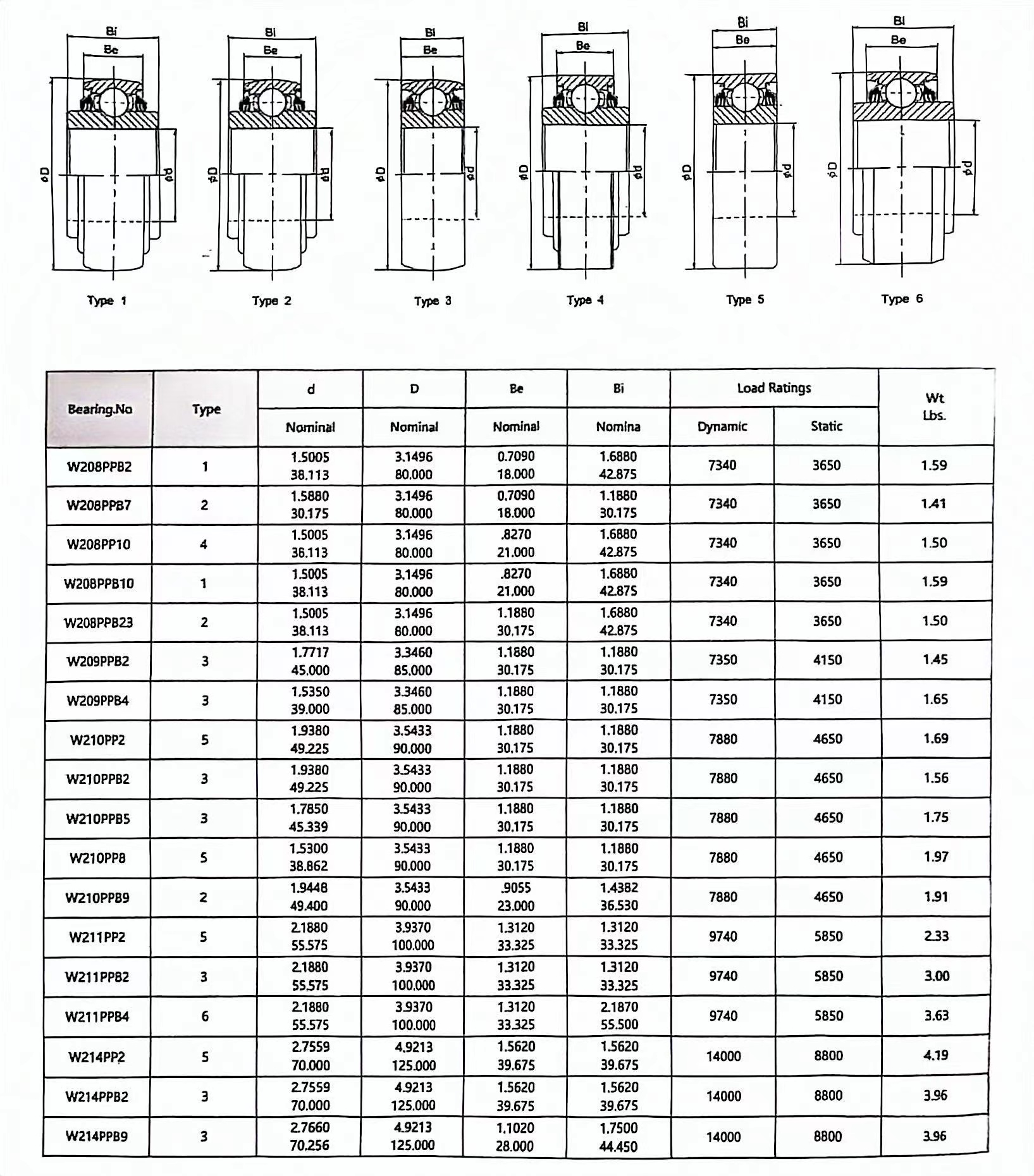

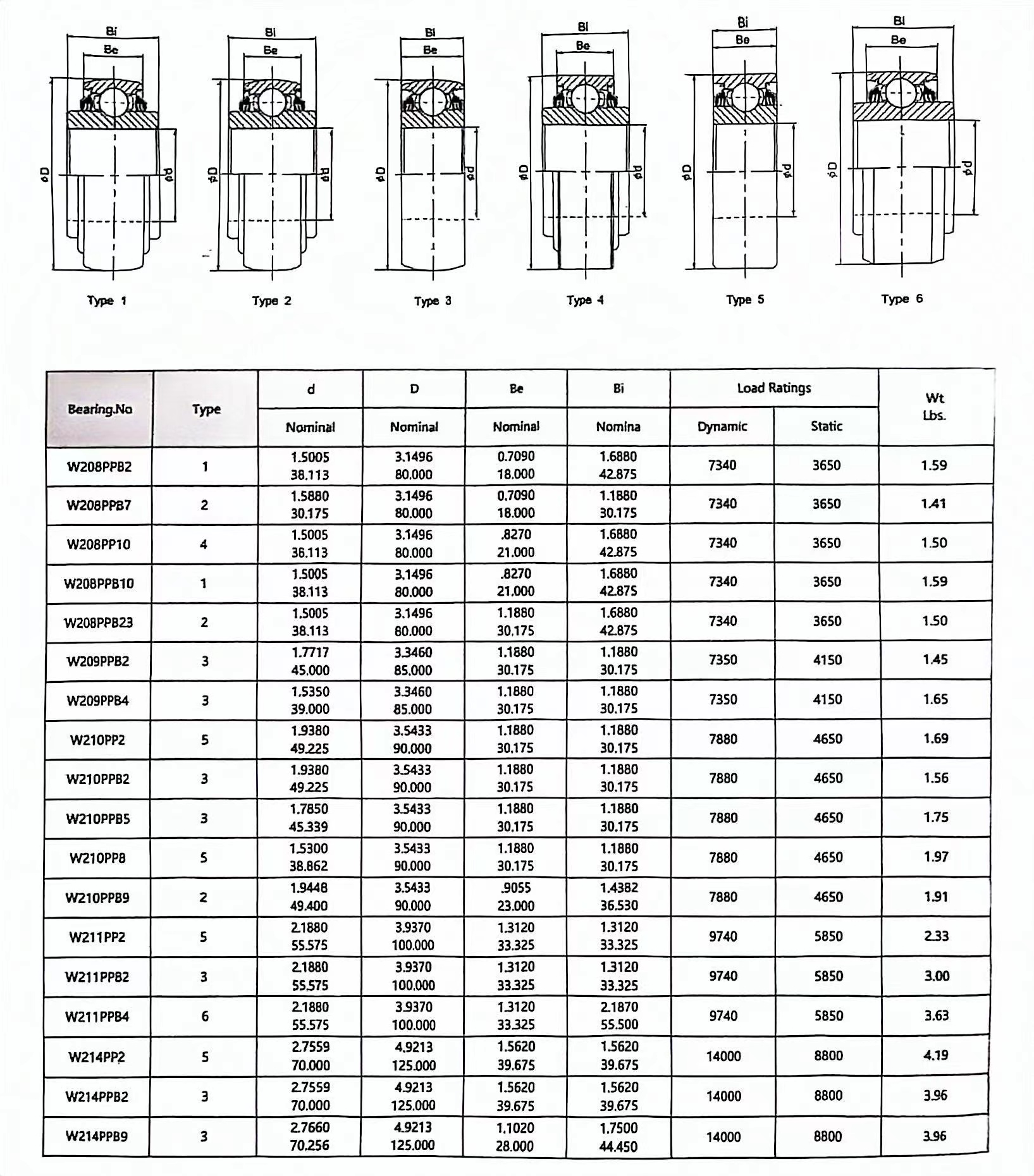

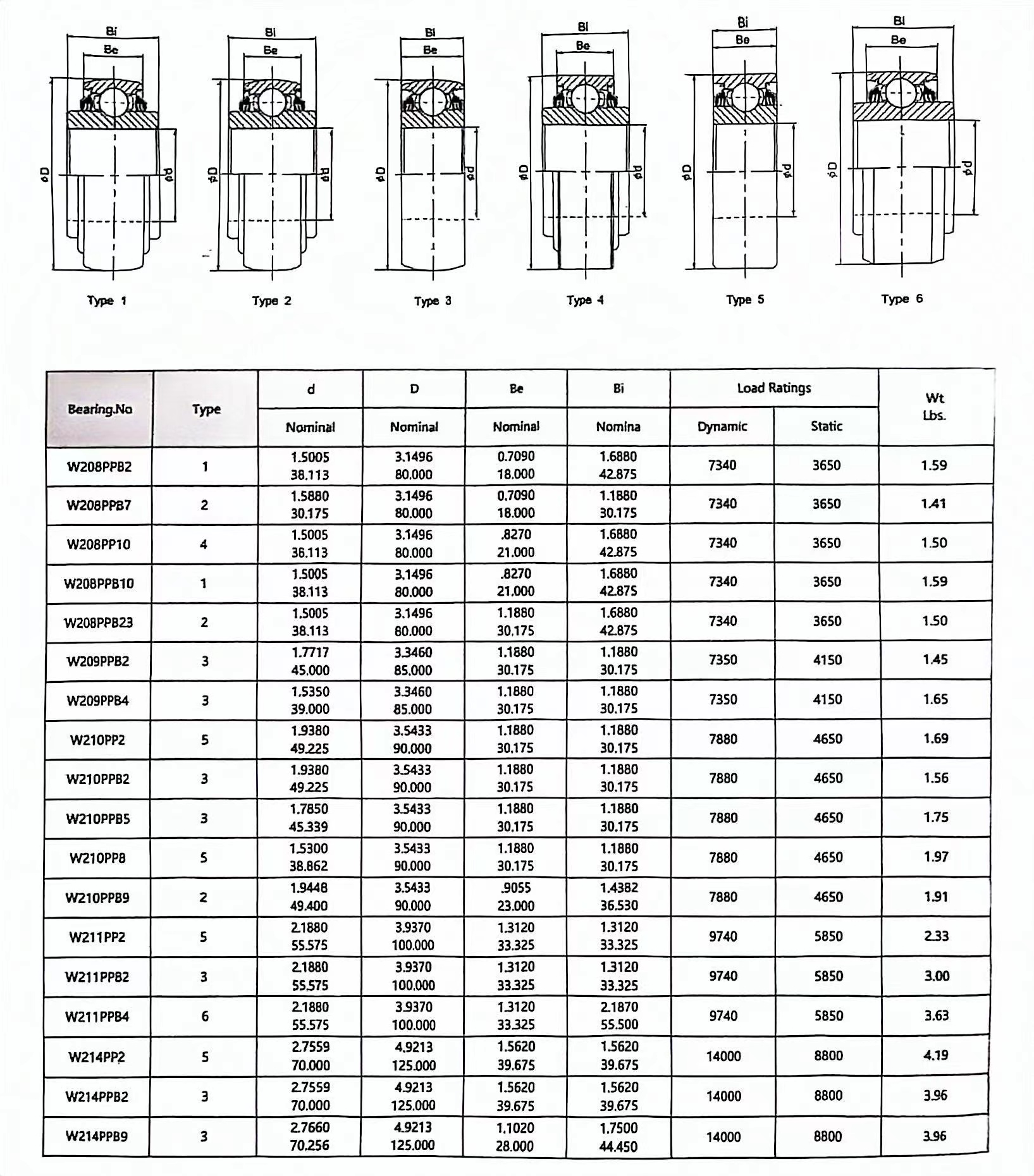

In the realm of engineering and industrial machinery, a key component that often goes unnoticed yet plays a pivotal role in ensuring smooth operation is the custom deep groove ball bearing. This marvel of modern technology has revolutionized the way we design and utilize bearings for various applications, from automotive to aerospace, and everything in between.

Deep groove ball bearings, with their distinctive design, feature a pair of raceways that run parallel to each other, creating a deep groove to house the. The term custom in this context refers to the ability to tailor these bearings to specific requirements, be it size, material, or load capacity, ensuring precise fit and optimal performance for the user.

One of the most significant advantages of custom deep groove ball bearings is their ability to handle heavy loads with precision. By adjusting the bearing dimensions, engineers can create a balance between load-bearing capacity and speed, making them suitable for high-velocity applications where friction must be minimized. Moreover, the deep groove design allows for greater radial and axial rigidity, translating to reduced wear and tear and longer service life.

Customization also extends to the choice of materials. Depending on the operating environment, bearings can be made from a range of materials, including stainless steel, chrome steel, or even advanced ceramics, each offering unique properties such as corrosion resistance, high-temperature tolerance, or increased durability. This versatility ensures that the bearing meets the demanding conditions it will encounter This versatility ensures that the bearing meets the demanding conditions it will encounter This versatility ensures that the bearing meets the demanding conditions it will encounter This versatility ensures that the bearing meets the demanding conditions it will encounter

This versatility ensures that the bearing meets the demanding conditions it will encounter This versatility ensures that the bearing meets the demanding conditions it will encounter custom deep groove ball bearing used for.

Furthermore, the deep groove design facilitates easy lubrication, which is crucial for minimizing friction and extending the bearing's lifespan. Customized oil grooves can be incorporated to optimize the flow of lubricant, further enhancing the bearing's efficiency and reducing maintenance requirements.

In the manufacturing sector, where downtime is costly, the use of custom deep groove ball bearings can lead to substantial productivity gains. With their robustness and precision, they reduce the risk of breakdowns and enable machines to operate at peak performance consistently.

In conclusion, custom deep groove ball bearings are a testament to the power of engineering innovation. Their ability to adapt to unique specifications, withstand heavy loads, and maintain exceptional performance make them indispensable in today's fast-paced industrial landscape. As technology continues to evolve, we can expect even more advanced and customized solutions from this versatile bearing type, shaping the future of efficient and reliable machinery.

custom deep groove ball bearing used for.

Furthermore, the deep groove design facilitates easy lubrication, which is crucial for minimizing friction and extending the bearing's lifespan. Customized oil grooves can be incorporated to optimize the flow of lubricant, further enhancing the bearing's efficiency and reducing maintenance requirements.

In the manufacturing sector, where downtime is costly, the use of custom deep groove ball bearings can lead to substantial productivity gains. With their robustness and precision, they reduce the risk of breakdowns and enable machines to operate at peak performance consistently.

In conclusion, custom deep groove ball bearings are a testament to the power of engineering innovation. Their ability to adapt to unique specifications, withstand heavy loads, and maintain exceptional performance make them indispensable in today's fast-paced industrial landscape. As technology continues to evolve, we can expect even more advanced and customized solutions from this versatile bearing type, shaping the future of efficient and reliable machinery.

This versatility ensures that the bearing meets the demanding conditions it will encounter This versatility ensures that the bearing meets the demanding conditions it will encounter

This versatility ensures that the bearing meets the demanding conditions it will encounter This versatility ensures that the bearing meets the demanding conditions it will encounter custom deep groove ball bearing used for.

Furthermore, the deep groove design facilitates easy lubrication, which is crucial for minimizing friction and extending the bearing's lifespan. Customized oil grooves can be incorporated to optimize the flow of lubricant, further enhancing the bearing's efficiency and reducing maintenance requirements.

In the manufacturing sector, where downtime is costly, the use of custom deep groove ball bearings can lead to substantial productivity gains. With their robustness and precision, they reduce the risk of breakdowns and enable machines to operate at peak performance consistently.

In conclusion, custom deep groove ball bearings are a testament to the power of engineering innovation. Their ability to adapt to unique specifications, withstand heavy loads, and maintain exceptional performance make them indispensable in today's fast-paced industrial landscape. As technology continues to evolve, we can expect even more advanced and customized solutions from this versatile bearing type, shaping the future of efficient and reliable machinery.

custom deep groove ball bearing used for.

Furthermore, the deep groove design facilitates easy lubrication, which is crucial for minimizing friction and extending the bearing's lifespan. Customized oil grooves can be incorporated to optimize the flow of lubricant, further enhancing the bearing's efficiency and reducing maintenance requirements.

In the manufacturing sector, where downtime is costly, the use of custom deep groove ball bearings can lead to substantial productivity gains. With their robustness and precision, they reduce the risk of breakdowns and enable machines to operate at peak performance consistently.

In conclusion, custom deep groove ball bearings are a testament to the power of engineering innovation. Their ability to adapt to unique specifications, withstand heavy loads, and maintain exceptional performance make them indispensable in today's fast-paced industrial landscape. As technology continues to evolve, we can expect even more advanced and customized solutions from this versatile bearing type, shaping the future of efficient and reliable machinery. Latest news

-

Top Spherical Roller Bearing Material Exporter - High-Performance Alloys

NewsAug.27,2025

-

Durable PLC 110-190 Spherical Roller Bearing for Mixer Reducer

NewsAug.26,2025

-

CSK-2RS Sprag Clutch One Way Bearing: Sealed, High Torque, Durable

NewsAug.25,2025

-

CKZ-D Series One Way Overrunning Clutch: Reliable Power Control

NewsAug.24,2025

-

203KRR3 Round Bore Series Bearings | Cylindrical Outer Ring, Precision

NewsAug.23,2025

-

Top Spherical Roller Bearing Material Exporter - High Performance

NewsAug.22,2025