Sep . 22, 2025 20:00 Back to list

4-Hole UCFC 200 Series Bearing with Flange Cartridge Units-Xingtai Botong Machinery Technology Co., Ltd|Heavy-Duty Self-Aligning

The UCFC 200 series bearing is a specialized mechanical component designed to enhance performance in industrial applications. Combining the functionalities of a pillow block and a flange cartridge bearing, this unit offers a robust solution for heavy-duty environments. This article provides an in-depth analysis of its features, advantages, technical specifications, and real-world applications.

Product Functionality and Design

The UCFC 200 series bearing is a unitized pillow block flange cartridge bearing, integrating a spherical outer ring with a built-in flange, a cylindrical inner ring, and a set of balls held by a cage. This design allows for seamless integration into machinery, providing both structural support and alignment flexibility.

The inner ring is mounted on the shaft, while the outer ring is secured within a housing. The flange on the outer ring enables direct bolting to machinery or structures, simplifying installation and maintenance. This configuration ensures easy accessibility for repairs or replacements without disassembling the entire system.

Key Advantages of UCFC 200 Series Bearings

1. Load-Bearing Capacity

One of the standout features of the UCFC 200 series is its ability to withstand heavy and shock loads. The load distribution across the balls, inner, and outer rings minimizes stress points, reducing the risk of mechanical failure. This makes it ideal for applications involving high-speed rotation or intense operational demands.

2. Self-Aligning Capability

The spherical outer ring allows for self-alignment, compensating for minor misalignments between the shaft and housing. This feature reduces friction and wear, extending the bearing's lifespan and improving machine efficiency. According to the National Institute of Standards and Technology (NIST), "self-aligning bearings are critical in applications where precise alignment is challenging" (NIST).

3. Contaminant Protection

Sealed on both sides, the UCFC 200 series effectively shields against dust, dirt, and moisture. This protection ensures consistent performance in harsh environments, making it a preferred choice for industries like agriculture and construction.

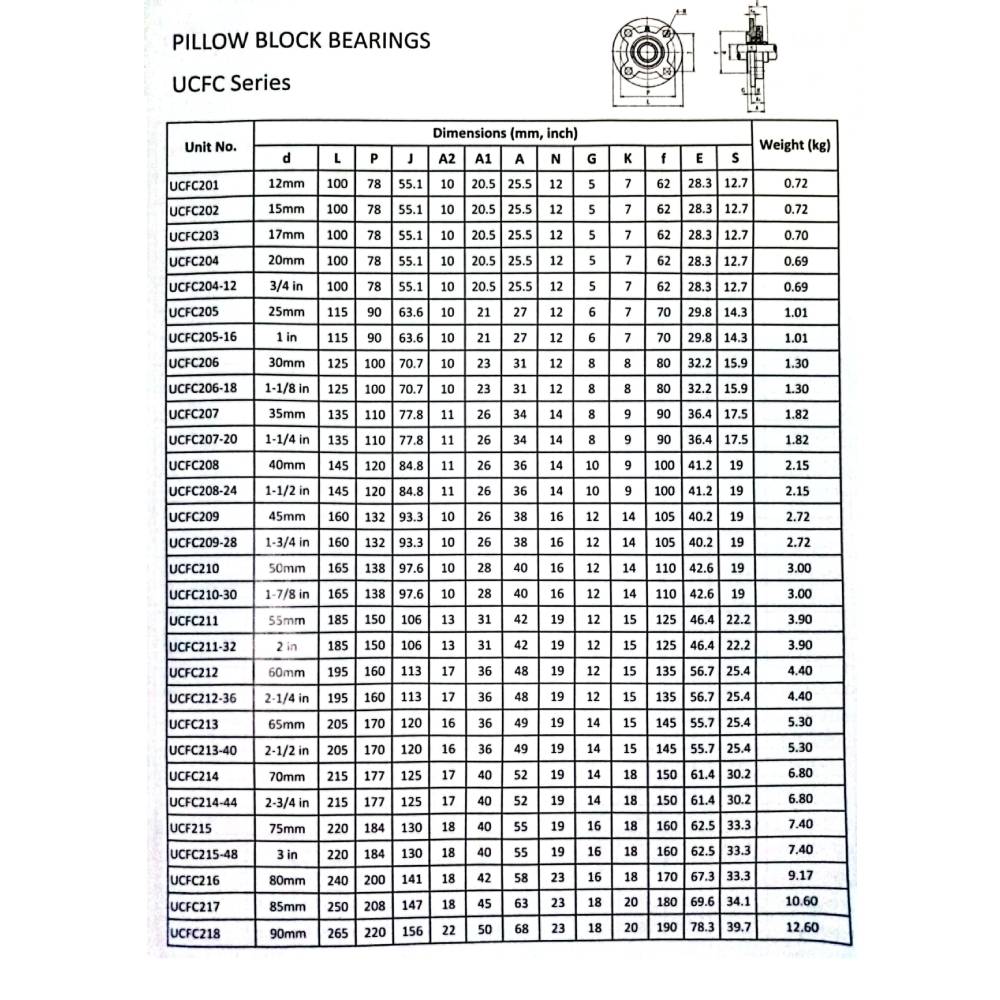

Technical Specifications

The UCFC 200 series is engineered to meet rigorous industrial standards. Below is a detailed specification table:

| Parameter | Details |

|---|---|

| Outer Ring | Spherical with built-in flange |

| Inner Ring | Cylindrical bore |

| Ball Configuration | Cage-held balls for even load distribution |

| Sealing | Double-sided sealing against contaminants |

| Material | High-strength steel for durability |

| Applications | Automotive, agricultural, construction, and heavy machinery |

Applications in Industrial Sectors

1. Automotive Industry

The UCFC 200 series is widely used in automotive engines and transmission systems. Its ability to handle high-speed rotation and heavy loads ensures reliable performance under demanding conditions. For example, it is often employed in drive shafts and suspension components.

2. Agricultural Machinery

In agricultural equipment such as tractors and harvesters, the UCFC 200 series provides robust support for rotating components. Its self-aligning feature compensates for uneven terrain, ensuring smooth operation even in challenging environments.

3. Construction Equipment

Construction machinery like excavators and cranes relies on the UCFC 200 series for its durability and resistance to shock loads. The flange design simplifies integration into complex mechanical systems, reducing downtime and maintenance costs.

Company Background: Xingtai Botong Machinery Technology Co., Ltd

The UCFC 200 series is produced by Xingtai Botong Machinery Technology Co., Ltd, a leading manufacturer of precision bearings. With over a decade of experience, the company specializes in spherical roller bearing material solutions, serving clients across industries globally.

Xingtai Botong is committed to innovation and quality, adhering to international standards such as ISO 9001. Their products are exported to more than 50 countries, with a reputation for reliability and technical excellence.

Packaging and Delivery

The UCFC 200 series is available in multiple packaging options to suit customer requirements:

- A. Plastic tubes + Carton + Wooden Pallet

- B. Roll Pack + Carton + Wooden Pallet

- C. Individual Box + Plastic Bag + Carton + Wooden Pallet

Standard exporting packaging ensures safe transportation, while customized options cater to specific client needs. For more details, visit the product page.

Conclusion

The UCFC 200 series bearing exemplifies engineering excellence, combining durability, self-alignment, and contamination resistance. Its versatility across industries makes it an indispensable component for modern machinery. For more information, explore the company website or contact their sales team directly.

References

National Institute of Standards and Technology (NIST) - For authoritative insights into bearing standards and applications.

Latest news

-

Custom Spherical Bearing Replacement | Tailored Solutions for Industry Uptime

NewsNov.22,2025

-

Custom Silicon Nitride Ceramic Bearings: Durable & Efficient Solutions for Advanced Industries

NewsNov.20,2025

-

Custom AG Bearings - Enhance Agricultural Equipment Performance and Durability

NewsNov.19,2025

-

Custom Ceramic Hanger Bearings: Durable Solutions for Today's Industry Needs

NewsNov.18,2025

-

Custom 6311 2RS Bearing - Durable, Tailored Bearings for Industry & Innovation

NewsNov.18,2025

-

Custom Agriculture Machinery Bearing - Durable, Tailored Bearing Solutions for Farming Equipment

NewsNov.15,2025