Jun . 27, 2024 12:00 Back to list

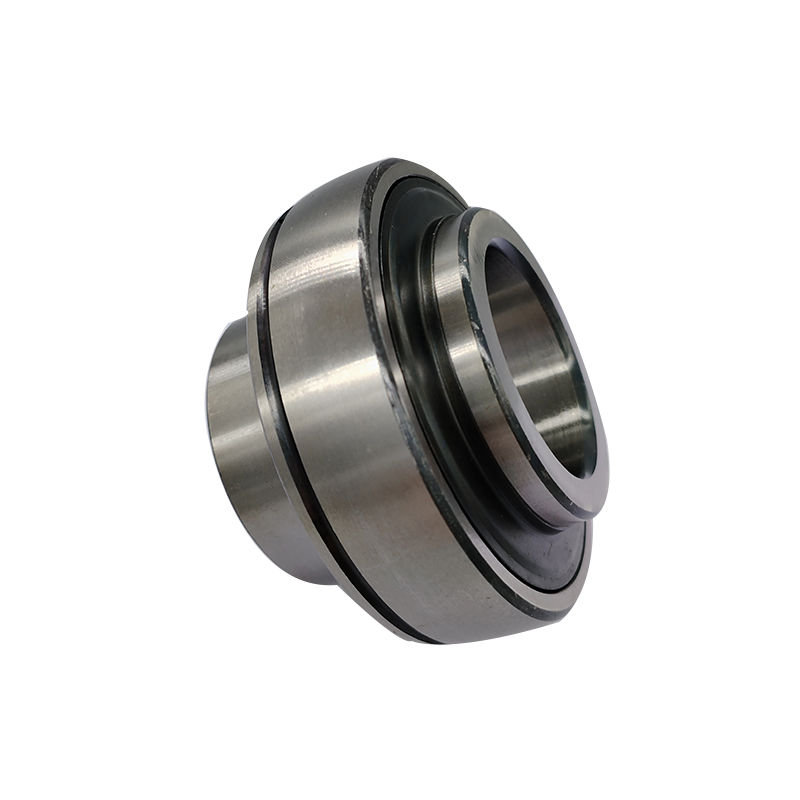

3. High-Quality Motor Bearing Lubricants

Greasing Motor Bearings Essential for Optimal Performance

In the realm of mechanical engineering, the proper greasing of motor bearings is paramount. Neglecting this critical maintenance task can lead to premature bearing failure, reduced equipment lifespan, and increased downtime. This article delves into the importance of greasing motor bearings and offers insights into selecting the right lubricant and maintenance schedule.

Motor bearings are subjected to immense friction, heat, and stress during operation. These forces can cause wear and tear, leading to the need for regular lubrication. Grease acts as a barrier between the moving parts of the bearing, reducing friction and preventing metal-to-metal contact. This, in turn, extends the life of the bearing and enhances its overall performance.

When selecting a grease for motor bearings, it is crucial to consider factors such as temperature range, load capacity, and environmental conditions. Different types of grease have varying properties that make them suitable for different applications. For instance, high-temperature greases are designed to withstand extreme heat, while heavy-duty greases are better suited for applications with high loads. It is essential to choose a grease that matches the specific requirements of your motor bearings.

In addition to selecting the right grease, it is also important to establish a proper maintenance schedule

In addition to selecting the right grease, it is also important to establish a proper maintenance schedule In addition to selecting the right grease, it is also important to establish a proper maintenance schedule

In addition to selecting the right grease, it is also important to establish a proper maintenance schedule

In addition to selecting the right grease, it is also important to establish a proper maintenance schedule

In addition to selecting the right grease, it is also important to establish a proper maintenance schedule greasing motor bearings suppliers. Regularly inspecting and reapplying grease ensures that the bearings remain properly lubricated and functioning optimally. Over time, the grease may become contaminated or dry out, leading to reduced performance and potential failure. Therefore, it is crucial to follow the manufacturer's recommendations for greasing intervals and to monitor the condition of the bearings regularly.

Failure to properly grease motor bearings can result in significant costs associated with repairs, replacements, and downtime. By investing in regular maintenance and using high-quality grease, you can extend the life of your motor bearings and ensure optimal performance. Additionally, proper greasing can help prevent accidents and injuries caused by malfunctioning machinery.

In conclusion, greasing motor bearings is a critical aspect of maintaining the longevity and efficiency of your equipment. By selecting the right grease and establishing a proper maintenance schedule, you can enjoy improved performance, reduced downtime, and lower operating costs. Remember to always consult with the manufacturer's recommendations to ensure that you are using the appropriate grease and maintenance practices for your specific application.

greasing motor bearings suppliers. Regularly inspecting and reapplying grease ensures that the bearings remain properly lubricated and functioning optimally. Over time, the grease may become contaminated or dry out, leading to reduced performance and potential failure. Therefore, it is crucial to follow the manufacturer's recommendations for greasing intervals and to monitor the condition of the bearings regularly.

Failure to properly grease motor bearings can result in significant costs associated with repairs, replacements, and downtime. By investing in regular maintenance and using high-quality grease, you can extend the life of your motor bearings and ensure optimal performance. Additionally, proper greasing can help prevent accidents and injuries caused by malfunctioning machinery.

In conclusion, greasing motor bearings is a critical aspect of maintaining the longevity and efficiency of your equipment. By selecting the right grease and establishing a proper maintenance schedule, you can enjoy improved performance, reduced downtime, and lower operating costs. Remember to always consult with the manufacturer's recommendations to ensure that you are using the appropriate grease and maintenance practices for your specific application.

In addition to selecting the right grease, it is also important to establish a proper maintenance schedule

In addition to selecting the right grease, it is also important to establish a proper maintenance schedule

In addition to selecting the right grease, it is also important to establish a proper maintenance schedule

In addition to selecting the right grease, it is also important to establish a proper maintenance schedule greasing motor bearings suppliers. Regularly inspecting and reapplying grease ensures that the bearings remain properly lubricated and functioning optimally. Over time, the grease may become contaminated or dry out, leading to reduced performance and potential failure. Therefore, it is crucial to follow the manufacturer's recommendations for greasing intervals and to monitor the condition of the bearings regularly.

Failure to properly grease motor bearings can result in significant costs associated with repairs, replacements, and downtime. By investing in regular maintenance and using high-quality grease, you can extend the life of your motor bearings and ensure optimal performance. Additionally, proper greasing can help prevent accidents and injuries caused by malfunctioning machinery.

In conclusion, greasing motor bearings is a critical aspect of maintaining the longevity and efficiency of your equipment. By selecting the right grease and establishing a proper maintenance schedule, you can enjoy improved performance, reduced downtime, and lower operating costs. Remember to always consult with the manufacturer's recommendations to ensure that you are using the appropriate grease and maintenance practices for your specific application.

greasing motor bearings suppliers. Regularly inspecting and reapplying grease ensures that the bearings remain properly lubricated and functioning optimally. Over time, the grease may become contaminated or dry out, leading to reduced performance and potential failure. Therefore, it is crucial to follow the manufacturer's recommendations for greasing intervals and to monitor the condition of the bearings regularly.

Failure to properly grease motor bearings can result in significant costs associated with repairs, replacements, and downtime. By investing in regular maintenance and using high-quality grease, you can extend the life of your motor bearings and ensure optimal performance. Additionally, proper greasing can help prevent accidents and injuries caused by malfunctioning machinery.

In conclusion, greasing motor bearings is a critical aspect of maintaining the longevity and efficiency of your equipment. By selecting the right grease and establishing a proper maintenance schedule, you can enjoy improved performance, reduced downtime, and lower operating costs. Remember to always consult with the manufacturer's recommendations to ensure that you are using the appropriate grease and maintenance practices for your specific application. Latest news

-

Durable PLC 110-190 Spherical Roller Bearing for Mixer Reducer

NewsAug.26,2025

-

CSK-2RS Sprag Clutch One Way Bearing: Sealed, High Torque, Durable

NewsAug.25,2025

-

CKZ-D Series One Way Overrunning Clutch: Reliable Power Control

NewsAug.24,2025

-

203KRR3 Round Bore Series Bearings | Cylindrical Outer Ring, Precision

NewsAug.23,2025

-

Top Spherical Roller Bearing Material Exporter - High Performance

NewsAug.22,2025

-

Durable UCFC202-09 Round Flange Housing 4-Bolt Ball Bearing

NewsAug.21,2025