Jun . 26, 2024 15:24 Back to list

3. High-Performance Spherical Bearings for Hydraulics

Custom Hydraulic Cylinder Spherical Bearings A Comprehensive Guide

Introduction

Hydraulic cylinders are vital components in a wide range of industrial and mobile applications. They are used to exert force and generate linear motion in machinery and equipment. One critical aspect of hydraulic cylinder performance is the bearing system, which reduces friction and wear, enhances efficiency, and extends the life of the cylinder. This article delves into custom hydraulic cylinder spherical bearings, their design, materials, benefits, and applications.

Design and Construction

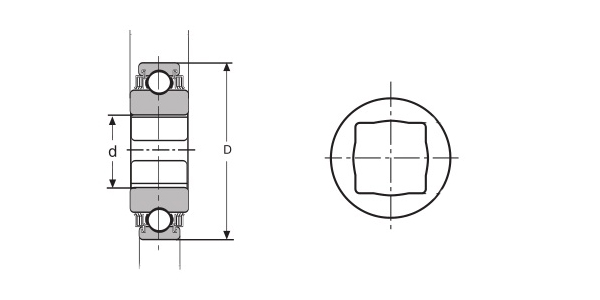

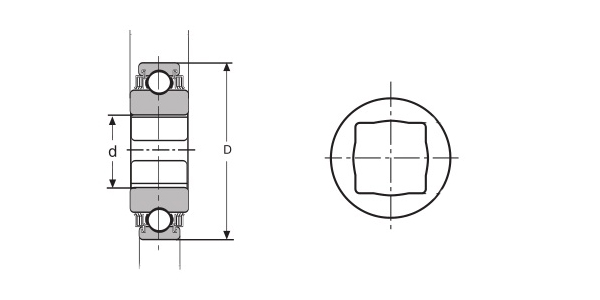

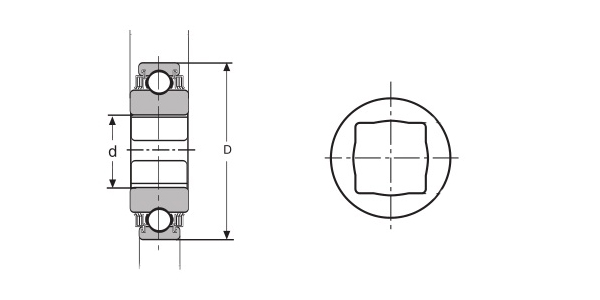

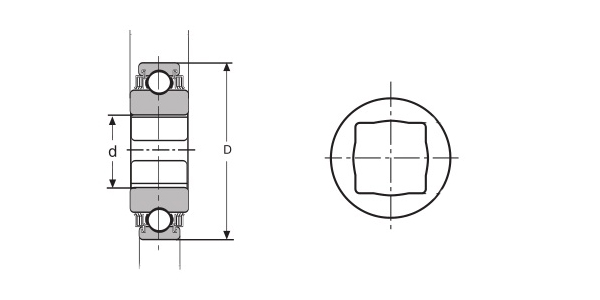

Spherical bearings are an essential part of hydraulic cylinders due to their ability to withstand high loads and provide a smooth, low-friction motion. These bearings consist of a steel cage that holds precision ball bearings, which roll along a spherical raceway machined into the inner surface of the cylinder tube and the outer surface of the piston rod. The cage maintains the balls in proper alignment and spacing, ensuring efficient operation.

Materials

The choice of materials for custom hydraulic cylinder spherical bearings is crucial for their performance and longevity. High-quality steel is commonly used due to its strength, hardness, and resistance to wear. Stainless steel is also popular for its corrosion resistance, especially in harsh environments. In addition, some bearings may incorporate a polymer or composite material for improved lubrication and reduced friction.

Benefits

Custom hydraulic cylinder spherical bearings offer numerous advantages over traditional plain bearings or roller bearings

Benefits

Custom hydraulic cylinder spherical bearings offer numerous advantages over traditional plain bearings or roller bearings Benefits

Custom hydraulic cylinder spherical bearings offer numerous advantages over traditional plain bearings or roller bearings

Benefits

Custom hydraulic cylinder spherical bearings offer numerous advantages over traditional plain bearings or roller bearings

Benefits

Custom hydraulic cylinder spherical bearings offer numerous advantages over traditional plain bearings or roller bearings

Benefits

Custom hydraulic cylinder spherical bearings offer numerous advantages over traditional plain bearings or roller bearings custom hydraulic cylinder spherical bearing. They can withstand high loads and misalignment, making them suitable for applications with complex motion profiles. Their low-friction design results in reduced energy loss and increased efficiency, leading to cost savings over time. Moreover, spherical bearings have a longer service life and require less maintenance compared to other types of bearings.

Applications

Spherical bearings are widely used in various industries, including construction, mining, agriculture, and manufacturing. They are ideal for heavy-duty applications where high loads and precise motion control are required. For example, in excavators and backhoes, spherical bearings help maintain the orientation of the bucket or arm while exerting significant force. In manufacturing processes, they ensure smooth operation of robotic arms and conveyor systems.

Conclusion

Custom hydraulic cylinder spherical bearings are a critical component that enhances the performance and reliability of hydraulic cylinders. By providing a smooth, low-friction motion and withstanding high loads and misalignment, these bearings play a vital role in a wide range of industrial and mobile applications. With their durability, efficiency, and versatility, spherical bearings are an excellent choice for customers seeking to optimize their hydraulic systems.

custom hydraulic cylinder spherical bearing. They can withstand high loads and misalignment, making them suitable for applications with complex motion profiles. Their low-friction design results in reduced energy loss and increased efficiency, leading to cost savings over time. Moreover, spherical bearings have a longer service life and require less maintenance compared to other types of bearings.

Applications

Spherical bearings are widely used in various industries, including construction, mining, agriculture, and manufacturing. They are ideal for heavy-duty applications where high loads and precise motion control are required. For example, in excavators and backhoes, spherical bearings help maintain the orientation of the bucket or arm while exerting significant force. In manufacturing processes, they ensure smooth operation of robotic arms and conveyor systems.

Conclusion

Custom hydraulic cylinder spherical bearings are a critical component that enhances the performance and reliability of hydraulic cylinders. By providing a smooth, low-friction motion and withstanding high loads and misalignment, these bearings play a vital role in a wide range of industrial and mobile applications. With their durability, efficiency, and versatility, spherical bearings are an excellent choice for customers seeking to optimize their hydraulic systems.

Benefits

Custom hydraulic cylinder spherical bearings offer numerous advantages over traditional plain bearings or roller bearings

Benefits

Custom hydraulic cylinder spherical bearings offer numerous advantages over traditional plain bearings or roller bearings

Benefits

Custom hydraulic cylinder spherical bearings offer numerous advantages over traditional plain bearings or roller bearings

Benefits

Custom hydraulic cylinder spherical bearings offer numerous advantages over traditional plain bearings or roller bearings custom hydraulic cylinder spherical bearing. They can withstand high loads and misalignment, making them suitable for applications with complex motion profiles. Their low-friction design results in reduced energy loss and increased efficiency, leading to cost savings over time. Moreover, spherical bearings have a longer service life and require less maintenance compared to other types of bearings.

Applications

Spherical bearings are widely used in various industries, including construction, mining, agriculture, and manufacturing. They are ideal for heavy-duty applications where high loads and precise motion control are required. For example, in excavators and backhoes, spherical bearings help maintain the orientation of the bucket or arm while exerting significant force. In manufacturing processes, they ensure smooth operation of robotic arms and conveyor systems.

Conclusion

Custom hydraulic cylinder spherical bearings are a critical component that enhances the performance and reliability of hydraulic cylinders. By providing a smooth, low-friction motion and withstanding high loads and misalignment, these bearings play a vital role in a wide range of industrial and mobile applications. With their durability, efficiency, and versatility, spherical bearings are an excellent choice for customers seeking to optimize their hydraulic systems.

custom hydraulic cylinder spherical bearing. They can withstand high loads and misalignment, making them suitable for applications with complex motion profiles. Their low-friction design results in reduced energy loss and increased efficiency, leading to cost savings over time. Moreover, spherical bearings have a longer service life and require less maintenance compared to other types of bearings.

Applications

Spherical bearings are widely used in various industries, including construction, mining, agriculture, and manufacturing. They are ideal for heavy-duty applications where high loads and precise motion control are required. For example, in excavators and backhoes, spherical bearings help maintain the orientation of the bucket or arm while exerting significant force. In manufacturing processes, they ensure smooth operation of robotic arms and conveyor systems.

Conclusion

Custom hydraulic cylinder spherical bearings are a critical component that enhances the performance and reliability of hydraulic cylinders. By providing a smooth, low-friction motion and withstanding high loads and misalignment, these bearings play a vital role in a wide range of industrial and mobile applications. With their durability, efficiency, and versatility, spherical bearings are an excellent choice for customers seeking to optimize their hydraulic systems. Latest news

-

203KRR3 Round Bore Series Bearings | Cylindrical Outer Ring, Precision

NewsAug.23,2025

-

Top Spherical Roller Bearing Material Exporter - High Performance

NewsAug.22,2025

-

Durable UCFC202-09 Round Flange Housing 4-Bolt Ball Bearing

NewsAug.21,2025

-

25x52x44.4mm UEL205 Bearing with Eccentric Sleeve

NewsAug.19,2025

-

High Quality 6319 2RS Deep Groove Ball Bearing 95x200x45

NewsAug.18,2025

-

UCT205-15 Take Up Housing Pillow Block Bearing | Reliable

NewsAug.17,2025