Description

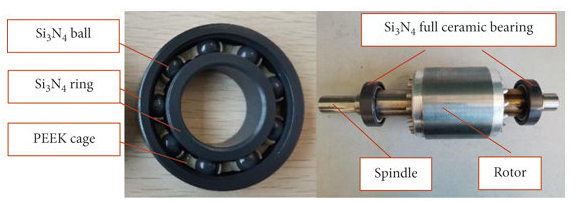

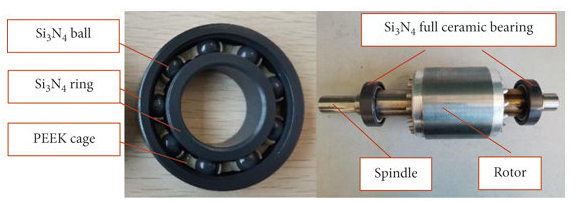

All-ceramic deep groove ball bearings have the characteristics of non-magnetic, electrical insulation, wear and corrosion resistance, oil-free self-lubrication, high temperature and cold resistance, etc. They can be used in more extreme harsh environments and special working conditions than zirconia (ZRO2) materials.

When the ball is full, it can be used in high temperature environments above 800°C. The PEEK cage can also be used at temperatures above 250°C. For polar temperatures (e.g. below -70°C), full ceramic bearings with PTFE cages or stainless steel 316 cages can be used. Normally, the normal radial clearance is C0.

When it is necessary to adapt to extreme environments, other clearances can be customized.

The advantages of all-ceramic bearings compared with steel bearings are:

1. Can be used at higher temperatures: Ceramic materials can stably maintain their mechanical properties at high temperatures, so they can be used in high temperature fields.

2. More suitable for occasions with temperature changes: Since the thermal expansion coefficient of ceramics is smaller than that of steel, the clearance of ceramic bearings is less affected by temperature changes than steel bearings, so they can be used in a wider temperature fluctuation range.

3. The thermal expansion coefficient is small, which helps to reduce thermal deformation.

4. Can work without oil: Ceramics have self-lubricating properties and can also be lubricated by media, so they can be used in high vacuum and inconvenient lubrication situations.

5. Resistant to acid, alkali and salt corrosion, and can be used in chemical corrosion situations.

6. Can be used in situations that require electrical insulation and no static electricity: Ceramics are non-conductive and non-static, and will not cause current ablation of steel bearings.

7. Can be used in magnetic environments: Ceramics are non-magnetic, and magnetic foreign matter or abrasive particles are not easy to adhere to the channel, which can reduce abrasive wear.